Souza Sezz

- Author: Mike Souza

- Subject Matter: 10R80/10L90

- Issue: New filter system

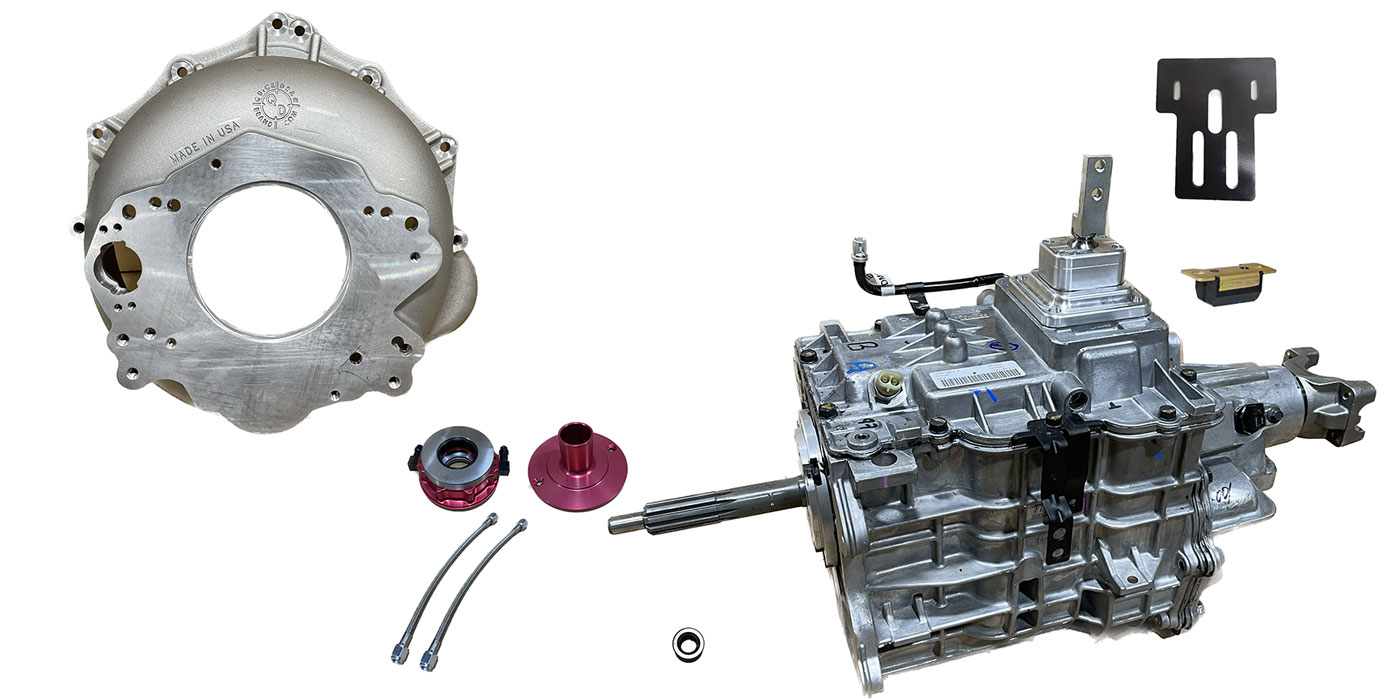

(Figure 1)

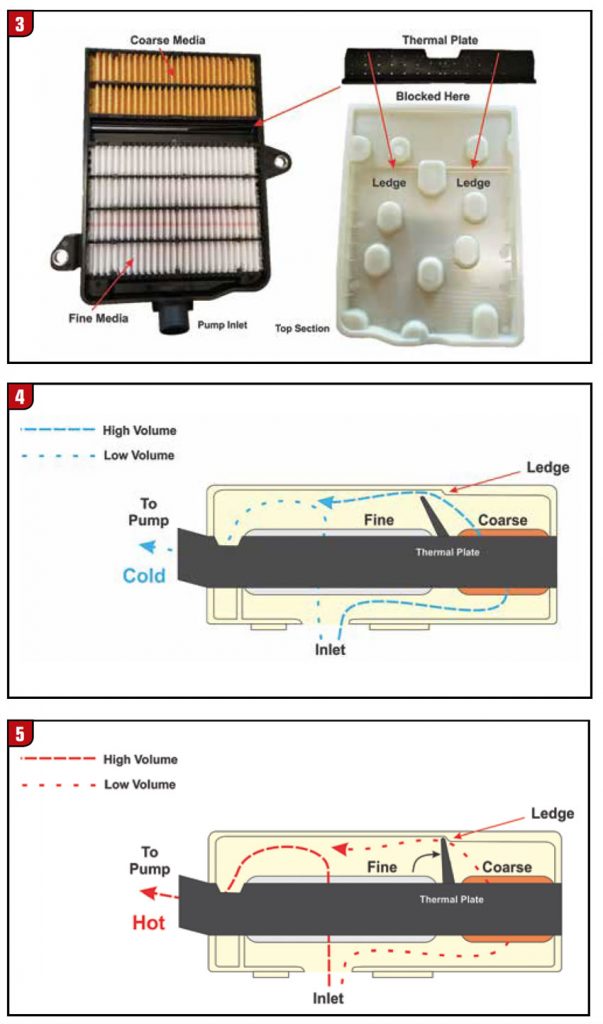

The new Ford and GM 10-speed transmission also has a newly developed filter and filtering system (Figure 2). This new filter design has two types of media, fine (white) and coarse (orange). The coarse material is common in most transmission filters, the fine media is a newer material and twice as large as the coarse media. This fine media is designed to catch the smaller particles of debris. There is a Thermal Plate in between the two types of media. The top of the thermal plate when heated will come into close contact on the ledge at the top section of the filter assembly (Figure 3). The way the filter works is kind of interesting. When the oil is cold (high viscosity) at startup, the fluid will flow through both the fine and coarse filter media. The fluid will travel in the path of least resistance as in this case restriction. The fluid viscosity when cold will pass through the coarse media much easier than the fine material. Meaning most of the fluid volume will flow through the smaller coarse media section (Figure 4) toward the back of the filter assembly.

This design will allow enough fluid volume to the pump during a cold start up and quickly prime the pump. As the fluid heats up (low viscosity), the Thermal Plate will move towards a slight ledge along the topside of the filter housing. This will restrict the smaller coarse media section, directing more volume of the fluid to flow through the larger fine media side of the filter assembly (Figure 5). Therefore, catching more of the finer particles of debris when the fluid is heated to operating temperature. The fluid having less viscosity should pass through the fine media section of the filter without starving the pump for oil. We have been told that the thermal plate has been eliminated. The engineering theory is the fluid viscosity will control the volume of fluid through each media in the same manner without the thermal plate. Although the part number for the Ford filter did not change, the part number for the Ford 10-speed filter is #HL3Z-7A098-A (referred to as a screen assembly). The part number that we found for the GM filter is #24291343 and it’s shown as updated. At the time that this article was written, the list cost of the Ford filter was about $48.22 and the GM was anywhere from $35.00 to $40.00 from different vendors.

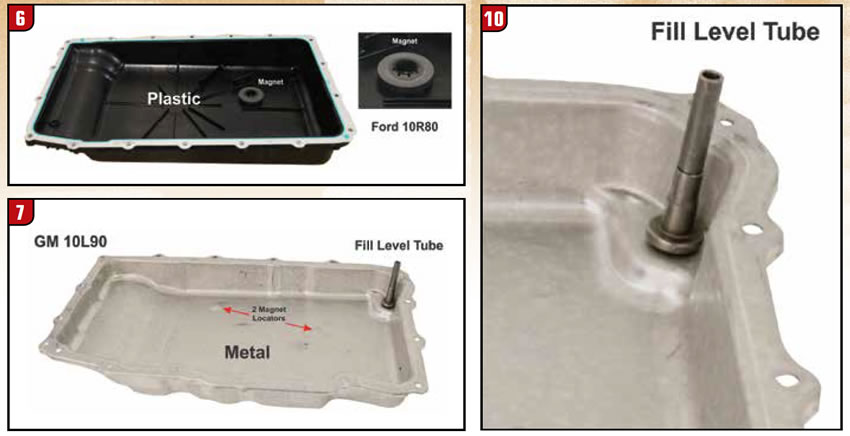

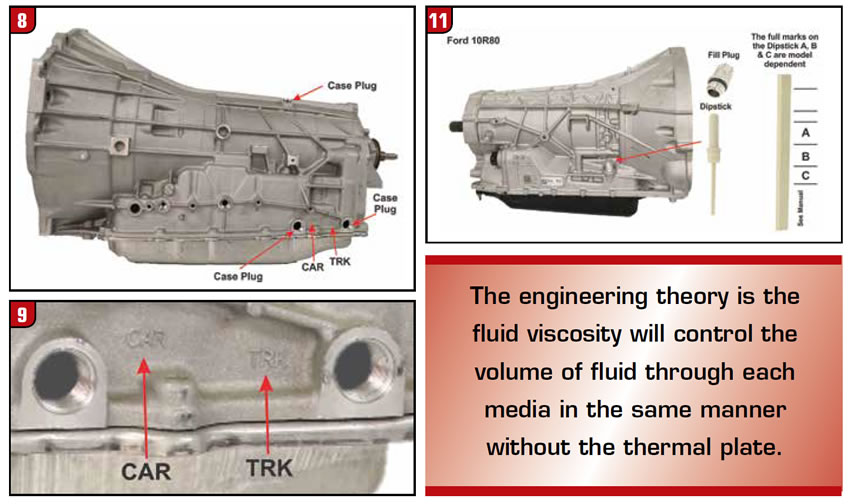

Although both transmissions are very similar, the sump (pan) on the Ford 10R80 model is plastic with a magnet held in place with a washer type clip (Figure 6). The GM 10L90 model has a metal pan with a fill level tube and fill plug located in the pan (Figure 7). There are two large case plugs on the rear driver’s side of the case just above the pan rail and another smaller one on the top of the case found only on GM models (Figure 8). One of the plugs on the side has embossed letters CAR and the other has TRK (Figure 9). There is no information found in the factory manual for these case plugs in the fluid level check or fill procedure. An educated guess would be CAR for car and TRK for truck, but that’s just an assumption. These case plugs are for factory use only. The two large case plugholes are not to be used for checking fluid level. The fill level tube in the pan is a bit higher than the bottom of the case plugholes (Figure 10). Filling the transmission to the bottom of the case plugholes would cause the transmission to be under filled. The Ford 10R80 has a fill plug and dipstick on the passenger side of the case like the 6R80 transmission. The dipstick has three different fill marks, A, B and C. These fill marks are model dependent and should be verified with factory information when the fluid level is checked (Figure 11). The fill procedure for the GM 10L90 and Ford 10R80 transmission can be found in Mitchell On Demand (MOD), Alldata or Identifix.

Thanks for reading the “Souza Sezz” column, see you next time!