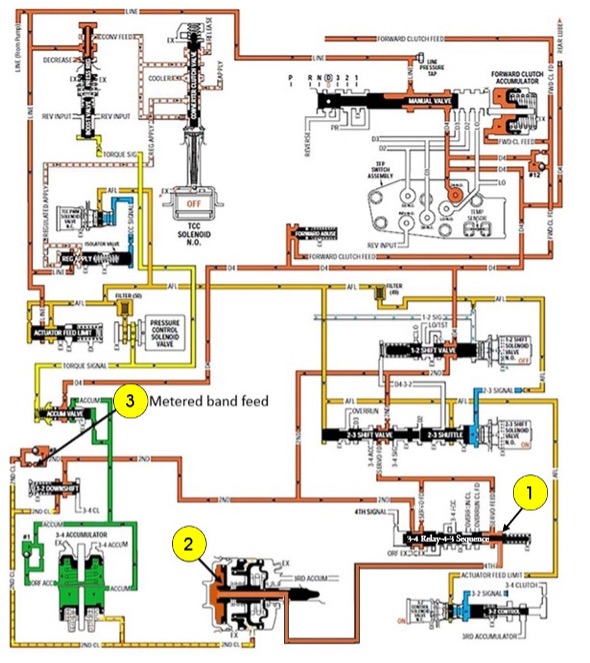

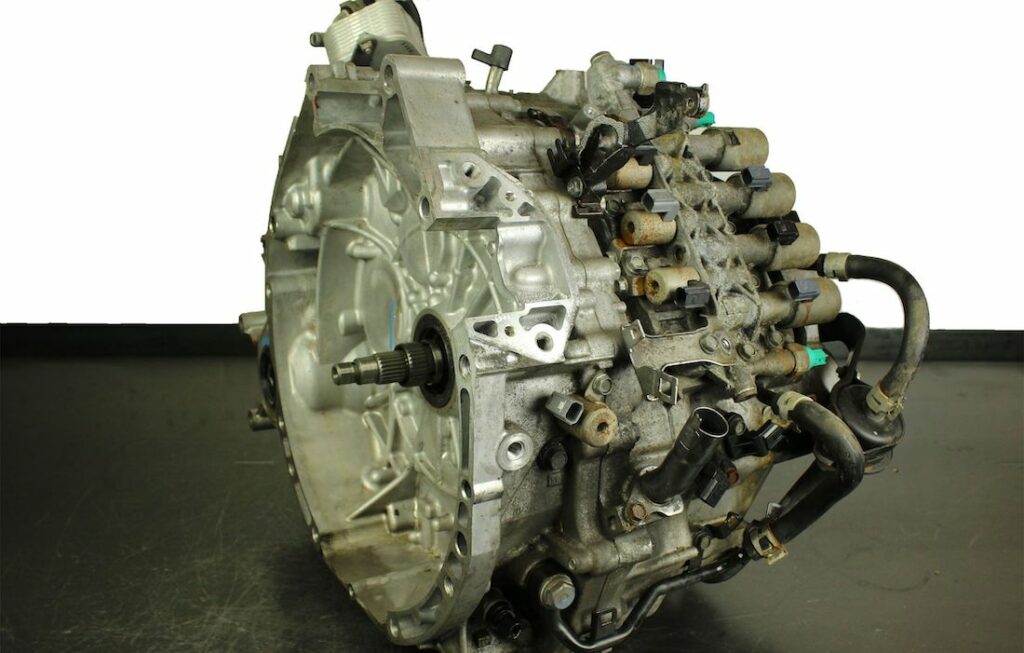

The Honda six-speed transmission has been on the bench of many specialty shops for one reason or another (figure 1). But, for those of you who have yet to lay your hands on one, mounted on the upper side of the unit is one of the largest, if not the largest solenoid and pressure switch assembly on a passenger car transmission you have ever seen (figure 2).

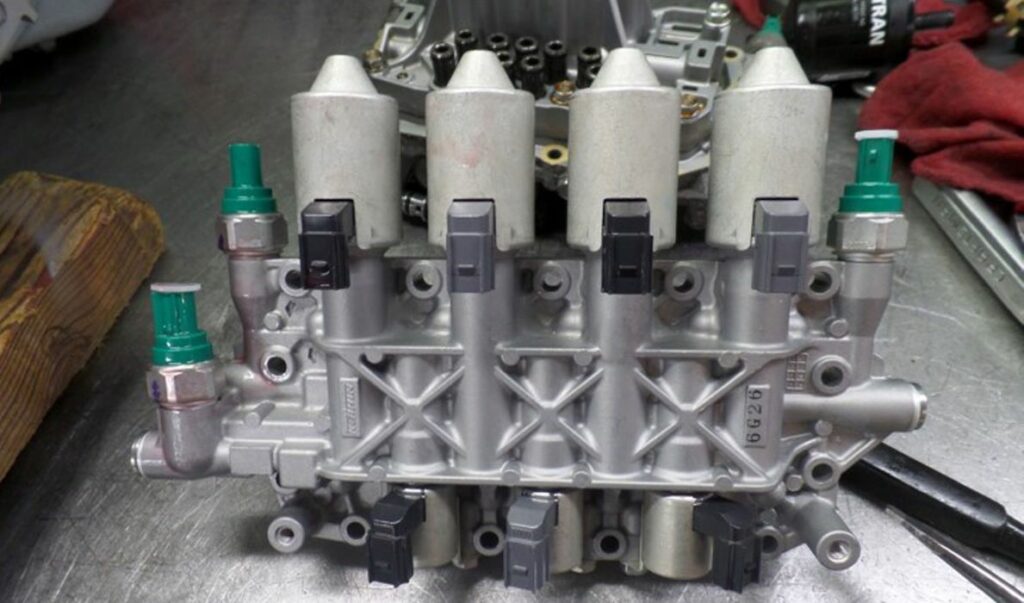

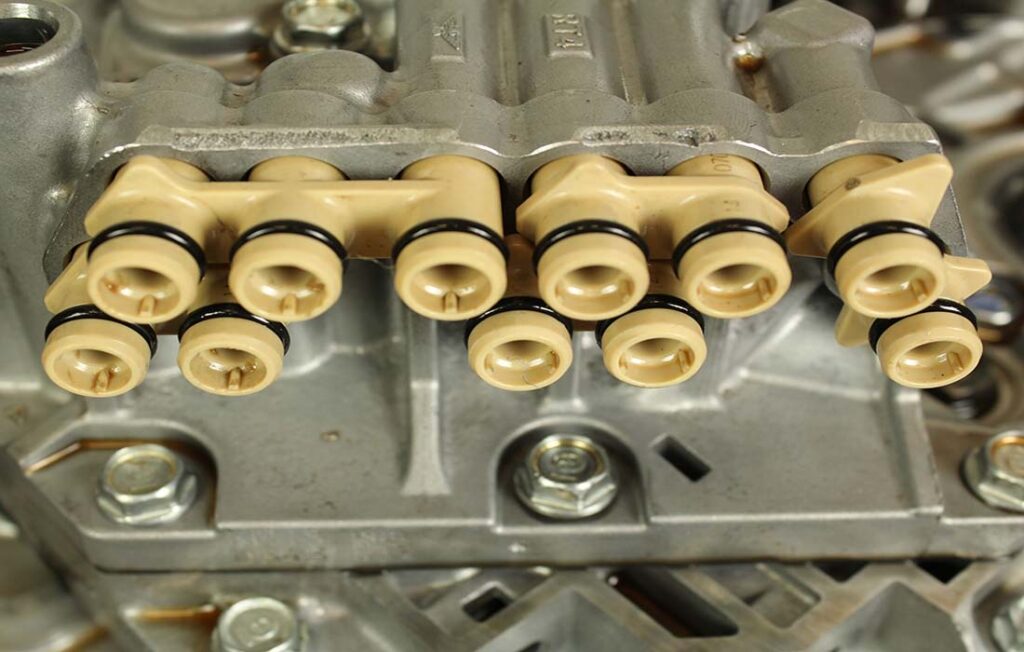

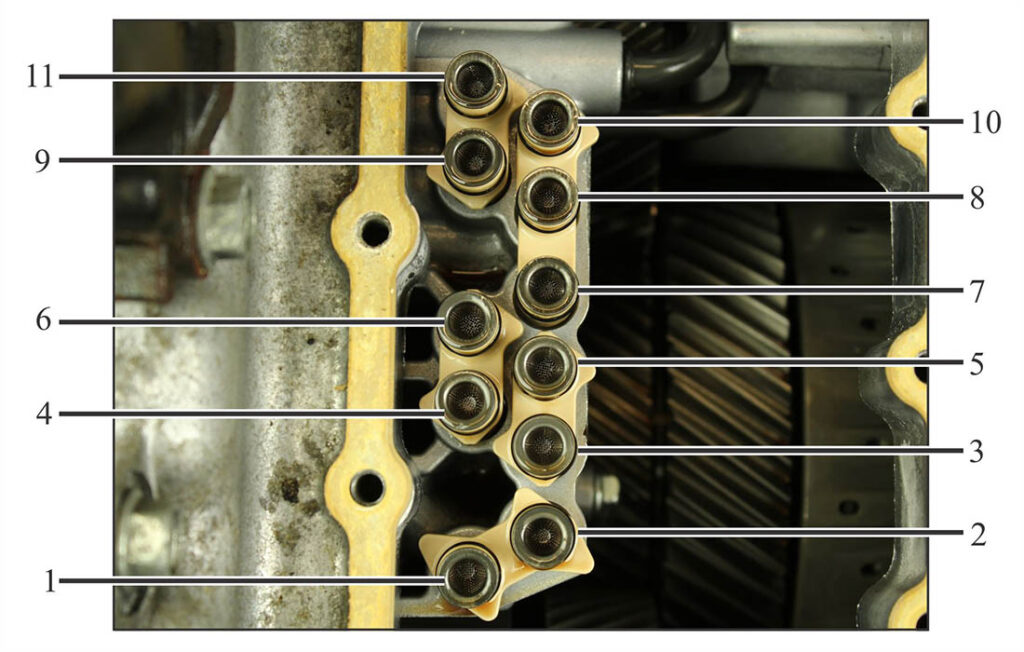

When this solenoid/pressure switch assembly is removed from the transmission (figure 3), you will see five plastic manifolds containing a total of eleven pass-through hydraulic circuit filter pipes. Each of these eleven pipes has its own filter screen cups in them (figure 4). It is quite easy to lose a few of them as they are not integral to the pipe. However, they can be removed (figure 5). So, if you are not aware of this, they can fall out unnoticed and magically disappear.

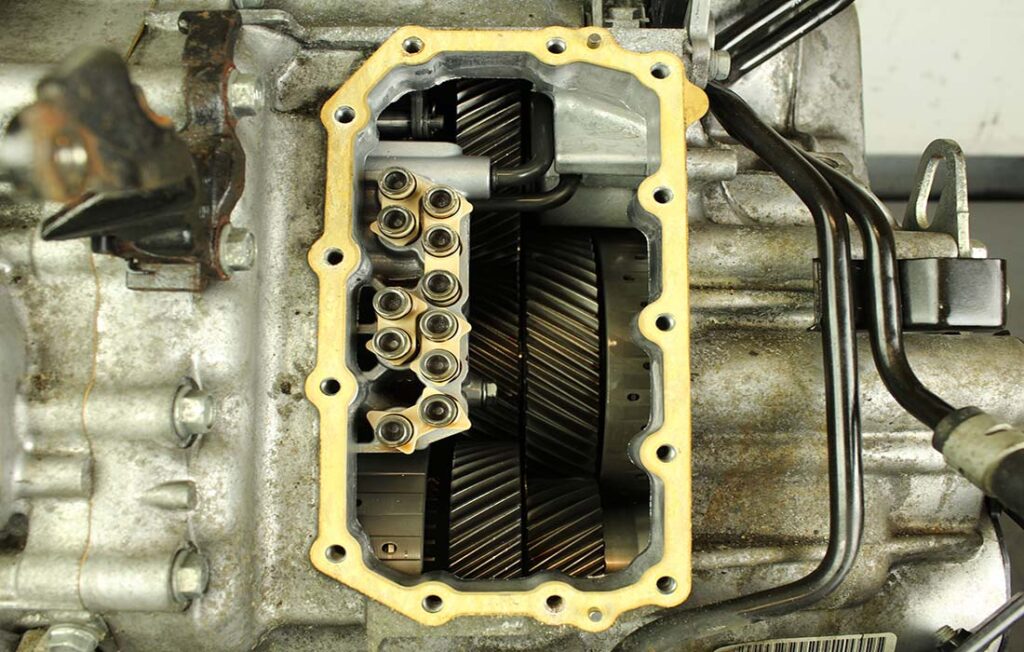

These filter pipe manifolds are strategically keyway placed into an internally mounted adapter housing (figure 6). Honda calls this adapter housing “the manual valve body.” The O-rings located closest to the end of these pipes is the side that presses into this manual valve body (figure 7).

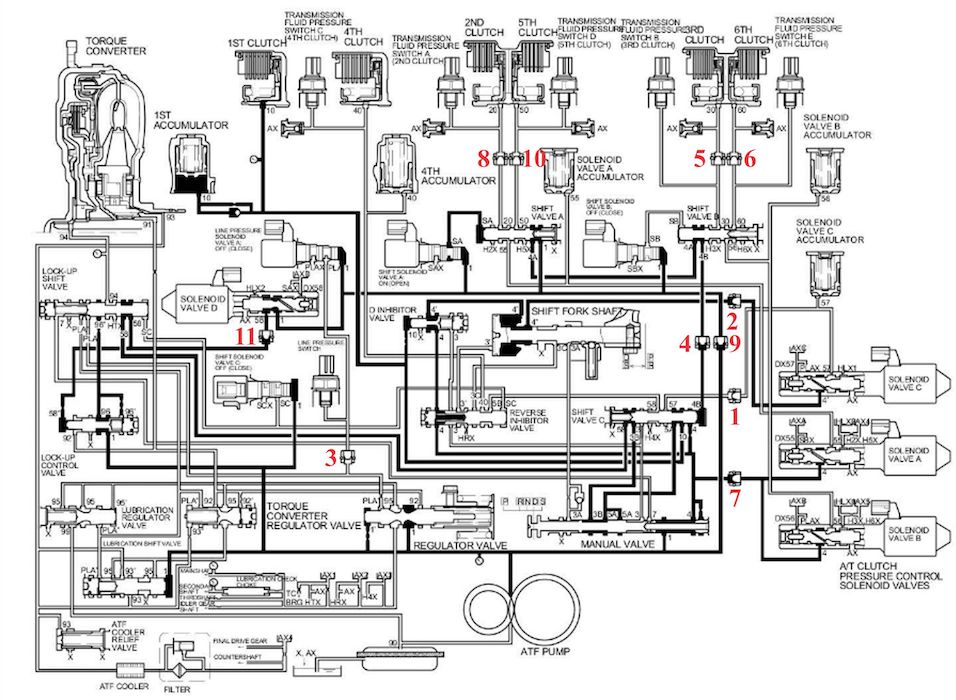

The question that comes up now and again from curious minds has been, “Are the functions of these filter pipes identified by Honda”? And the answer is both yes and no. “Yes,” in that they can be seen in hydraulic schematics showing their individual functions, but “No” in that they are not individually identified in their repair manual.

In figure 8, each of these hydraulic filter pipes is numbered. These numbers are then placed next to their corresponding filter location in Honda’s hydraulic schematic seen in figure 9.

These are the hydraulic functions of each of these filter pipes in the manifold pipeway:

- Filter # 1 filters the circuit between AT Clutch Pressure Control Solenoid Valve C, Solenoid Valve C Accumulator and Shift Valve C;

- Filter # 2 filters the circuit between AT Clutch Pressure Control Solenoid Valve C and the Shift Fork Shaft;

- Filter # 3 filters the circuit between Line Pressure Solenoid Valve A, Line Pressure Switch, Regulator Valve and the Lock-Up Shift Valve;

- Filter # 4 filters the circuit between Shift Valve B and Shift Valve C;

- Filter # 5 filters the circuit between Shift Valve B, Transmission Fluid Pressure Switch B and the 3rd Clutch;

- Filter # 6 filters the circuit between Shift Valve B, Transmission Fluid Pressure Switch E and the 6th Clutch;

- Filter # 7 filters the circuit between AT Clutch Pressure Control Solenoid Valve A, AT Clutch Pressure Control Solenoid Valve B and the Manual Valve (Pressure Supply;)

- Filter # 8 filters the circuit between Shift Valve A, Transmission Fluid Pressure Switch A and the 2nd Clutch;

- Filter # 9 filters the circuit between AT Clutch Pressure Control Solenoid Valve D, Line Pressure Solenoid A, Shift Solenoid Valve A, Shift Solenoid Valve B and the Manual Valve (Pressure Supply);

- Filter # 10 filters the circuit between Shift Valve A, Transmission Fluid Pressure Switch D and the 5th Clutch; and

- Filter # 11 filters the circuit between AT Clutch Pressure Control Solenoid Valve D and the Lock-up Shift Valve.