The 2014 Ford Edge SEL with a 3.5L engine (figure 1) and a 6F50 transmission can also be equipped with an AWD system. This would include a Power Transfer Unit (PTU) attached to the transmission with a rear driveshaft going to the Read Differential Unit (RDU). The RDU comprises a differential assembly along with a viscous coupling assembly controlled by an Active Torque Control (ATC) coupling solenoid. The system is designed to monitor vehicle conditions continuously and seamlessly adjust torque distribution between the front and rear wheels. When it is functioning correctly, there should be no perception of this taking place when launching or driving the vehicle.

If any overheating is detected, the system is designed to stop all slip and lock the clutches completely to cool the coupling while transferring power to the rear wheels. If the assembly does not cool down, it fully releases, pushing all the power to the front wheels. Despite there being a protective overheat strategy in place, the assembly can overheat enough times to seize clutch plates in this coupling resulting in wheel hop on turns and the driveline windup skips on straight drives.

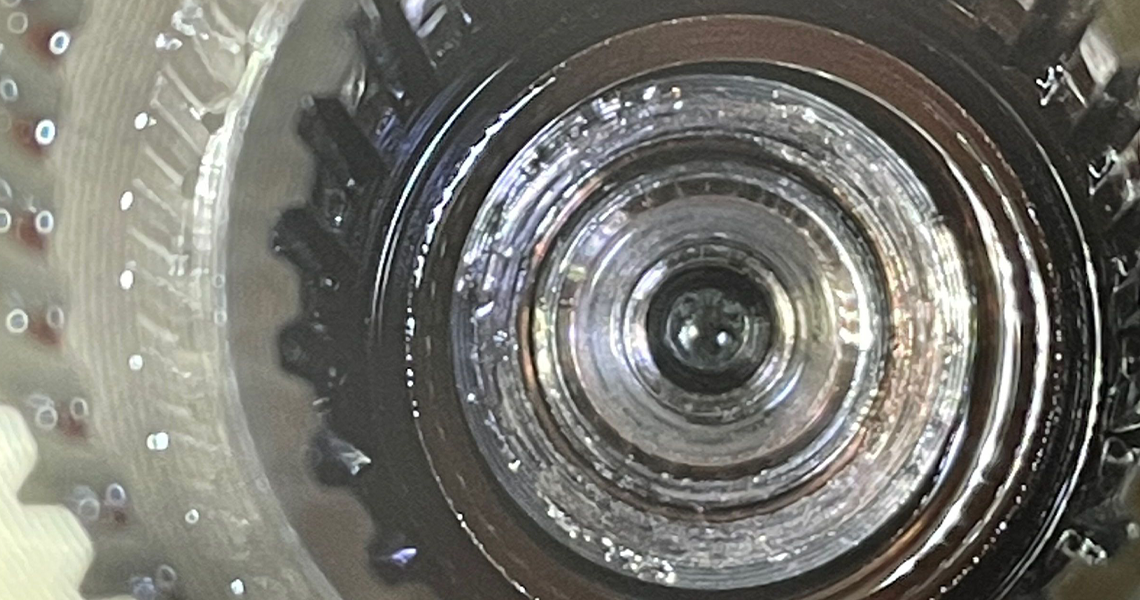

The dilemma is that this assembly is non-serviceable. Craig at AACTION Transmissions in Pembroke Pines experienced this problem. The RDU can be seen in figures 2 and 3. While figures 4 and 5 show the viscous coupling assembly separated from the rear differential. It is an enclosed assembly that cannot be purchased separately. The entire RDU needs to be purchased to correct this condition.

Aside from having a seized viscous coupling assembly, this unit also suffered from fretting corrosion, as seen in the spline area. Most dialectic greases have a -40 to 400°F heat range. Above that range, this grease becomes compromised. Once this occurs, spline-to-spline rubbing and vibration deteriorates the metal, causing this condition. Eventually, if the coupling assembly did not seize, the spline will strip, causing a torque loss to the rear wheels.

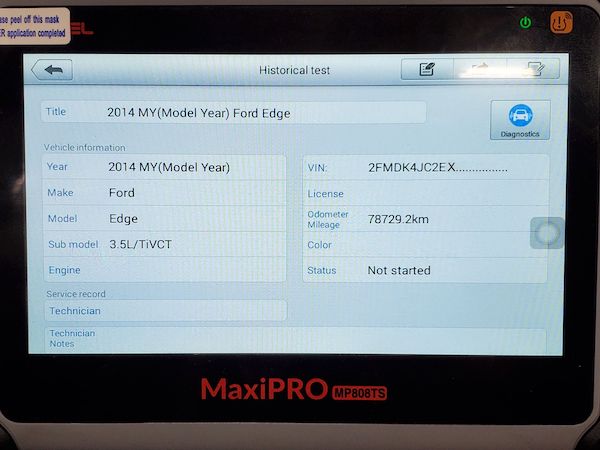

And, for whatever reason, once an RDU is determined to be defective, simply installing a new one does not complete the repair. Figure 6 shows the Active Torque Control (ATC) coupling solenoid bar code tag. It contains a strategy number that must be programmed into the PCM to function properly within factory tolerances. Very similar to the transmission’s solenoid strategy and ID numbers.

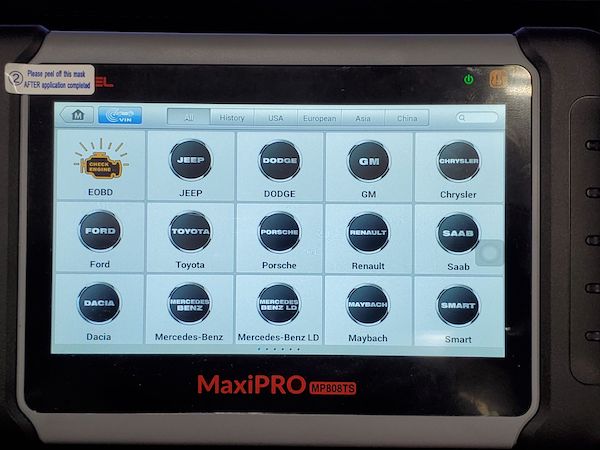

Programming this RDU is quick and straightforward if you know where to go and, of course, if you have the equipment to do the work. The Autel MaxiPRO MP808K (figure 7) got the job done for AACTION Transmissions. Other software and scan tools get the job done, like Forscan if you do not have Ford’s IDS.

The tip here is where to go to perform this programming. You may go to the transmission side of the software and not find it. You may then go to Programming and not find it there either. You will need to get into the PCM and select “Special Functions.” Once you locate the ATC-RDU programming function, using the bar code tag as seen in figure 6, obtain the code off of the bar code from the new RDU to be installed. The old one for this vehicle was 5439E3, as seen in figure 6. Once entered, the programming event only takes seconds.

There is a technical service bulletin from Ford (20-2165) for 2017-2019 Ford Escape 1.5L vehicles where the AWD-RDU exhibits a bump/clunk condition when turning at low speeds and parking lot maneuvers.

It reads as follows:

Some 2017-2019 Escape vehicles equipped with a 1.5L EcoBoost engine and all-wheel drive (AWD) may exhibit a bump or clunk from the rear drive unit (RDU) when turning at low speeds and parking lot maneuvers. This may be due to the software in the powertrain control module (PCM). To correct the condition, follow the Service Procedure to reprogram the PCM using operation number 202165A.

It is advisable to inform the customer that this vehicle is equipped with an adaptive transmission shift strategy that allows the vehicle’s computer to learn its unique parameters and improve shift quality. When the adaptive strategy is reset, the computer will begin a relearning process. This relearning process may result in firmer than usual upshifts and downshifts for several days.