The 6T40 was introduced in 2008 for General Motors front-wheel-drive cars in the Chevrolet Malibu and has gone through several changes throughout its three generations, specifically in the pump area. The 6T40 is closely related to the more lightweight 6T30 and the heavier duty 6T45 and 6T50. Generation one started phasing out during the 2012 model year. The generation two pump had a slightly different pressure regulator valve, but overall the first two 6T40 generations had the same pump layout.

The third generation of the 6T40 was introduced in 2015 with a completely redesigned pump to improve fuel economy. A remote axis pump setup was implemented to reduce the effort required by the engine to turn the pump, as previous generations were chain-driven by the converter. The new generation utilizes a variable vane-type pump that lowers power consumption during lower flow demand and at higher engine speeds.

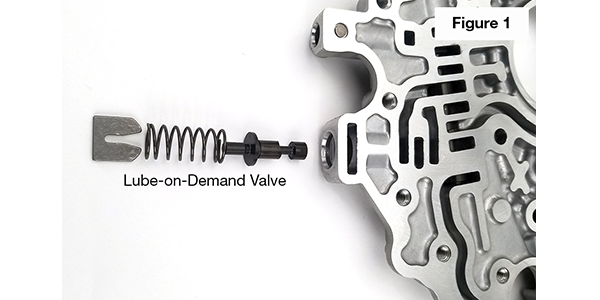

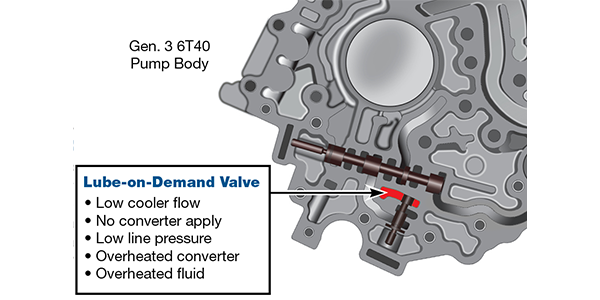

One of the unique features of the latest pump design is the lube-on-demand valve (Figure 1).

Under 87 psi, the valve stays closed and lube flow travels through an orifice in the separator plate. Above 87 psi, the valve opens and lube flow travels through two orifices, allowing the delivery of double the cooler flow in TCC apply in higher line pressure conditions (Figure 2). These unique features were all implemented in the interest of fuel conservation by minimizing the demand for the pump.

The lube-on-demand is a very active valve, and castings pulled from used examples show that the bore is highly prone to wear as it is visibly side-loaded. Some examples found in the real world have pulled 0 in-Hg vacuum when tested. Wear in this bore will cause the converter feed pressure to be directed straight to the exhaust. This can cause converter apply issues, lube/cooler flow issues resulting in overheating and reduced line pressure.

What can you do?

Since wear in this bore is inevitable, whenever a drivability issue is related to converter apply, low line pressure, lube/cooler flow issue, or general rebuild, the lube-on-demand valve should be vacuum tested to check if the wear is excessive (Figure 3).

If it is excessive, the aftermarket has responded with a solution to correct the valve-to-bore clearance and restore the function of this unique feature.

Jason Larochelle is a Sonnax product support representative. He is a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax technicians.