The TorqueFlite transmission has been around since mid-to-late 1950s. There have been many changes surrounding the manual shaft and rooster comb through the years. This transmission shaft controls the position of the manual valve that directs oil for the gear ranges, but it also is used for a Reverse light control as well as Park/Neutral safety control. As it evolved, changes to these safety backup switches caused extra stress against the rooster comb that posed new challenges to the technician.

Constant switch spring tension now is creating wear that needs to be addressed to help prevent issues such as shifter bind and shifter position detent ball and spring bore wear. Wear in this area became more evident when the name on the Park/Neutral switch changed to what now is called a MUX switch (Figure 1).

This new design switch now also provides signals to the dashboard for the shifter position. Indicator lights now show the position of the shifter P-R-N-D/OD-2-1. This new style of switch adds spring tension inside the switch. This can cause extra stress against the rooster comb and create new issues such as:

- Shift cable stress (stretching because of binding).

- Stuck in park.

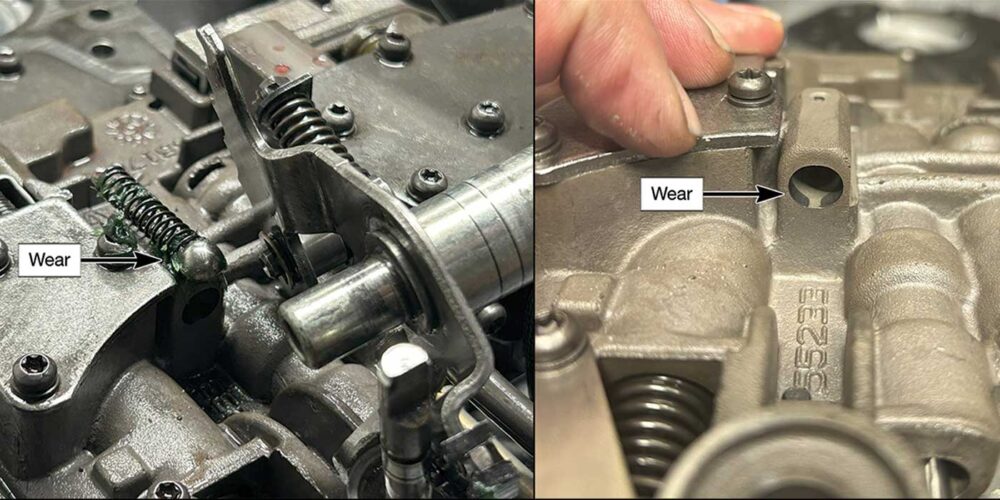

- Aggravated wear at the shift detent ball and spring pocket in the valve body (see Figure 2).

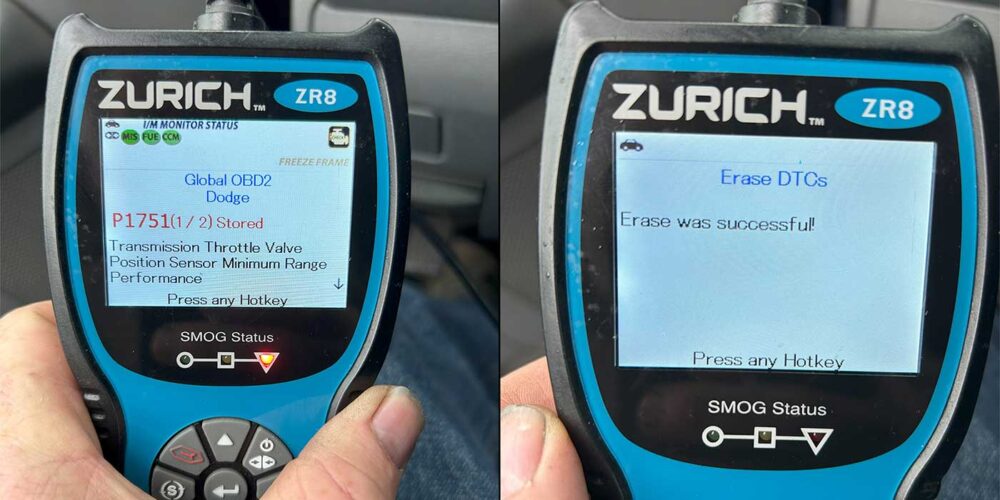

- 48RE – TTVA codes: TV electric motor bind caused by TV rod binding against the inside of the manual shaft, not allowing it to self-calibrate (see Figure 3).

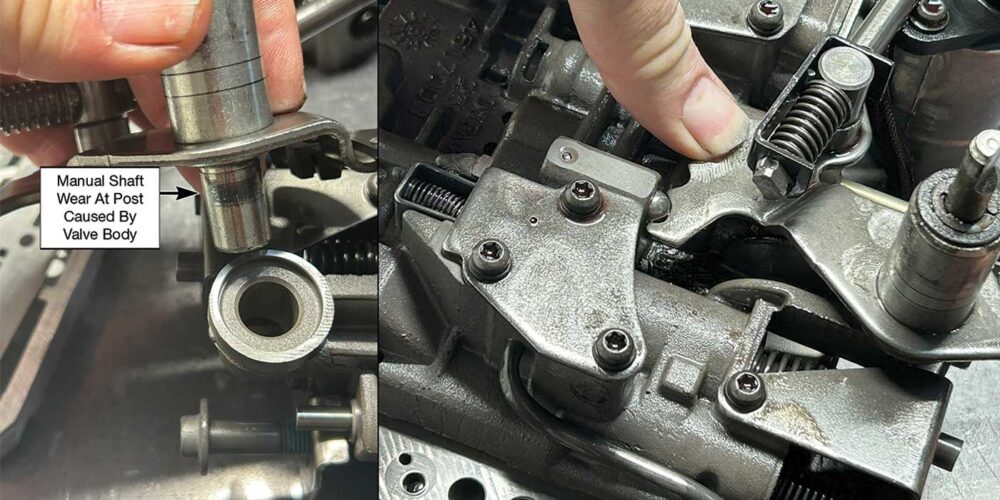

Keep in mind, this wear typically starts because the manual shaft is being pushed sideways by the spring force of the switch. Over time, the more that the transmission is shifted through the gears, the shaft causes the transmission case manual shaft bore to wear where the manual shaft seal rides and where it is supposed to be kept centered (Figure 4).

The case guide hole goes from being a perfect circle to an oval opening. This hole in the transmission case — where the manual shift extends through — is used to keep the manual shaft centered along with a peg extension at the end that extends from the bottom of the manual shaft and fits into the valve body.

When wear happens in the case seal area, one of the first things you’ll notice is that the shifter does not want to move freely. This is most obvious when the shifter sticks in Park. This case wear changes the angle of the shaft, allowing it to rock back and forth in the valve body pocket. This causes the rooster comb, which is a flat plate that’s part of the shaft that controls the locked-in positions of the manual valve, to no longer ride true center to the detent ball (spring loaded in a pocket of the valve body) controlling stopping points. When this happens, this detent ball area must be addressed to assure proper position of the manual valve.

An aftermarket workaround for the sticking in Park is often the technician filing or grinding on the rooster comb. When properly repaired, both the case shaft hole and the peg that is on the bottom of the shaft are supported in the valve body, allowing the shifting to become stress-free as designed.

Addressing the wear area in the case and testing the shaft in the valve body is very simple. Case wear is easily identified. Typically, there is noticeable wear on the side of the shift shaft at the area where it rides in the case. Also when installed into the case, the wear is easily identified with an open gap to one side of the shaft viewed (evidence of wear at the case) with the shaft seal removed. This wear often causes the manual shaft seal to also leak.

Testing for shift shaft post wear on the valve body side is fairly simple. With the detent ball and spring removed, see if it can be rocked back and forth like a teeter-totter. If there is rocking or play, the shaft is typically worn out (Figure 5).

It is important to take the time and inspect these areas especially when dealing with codes or binding and make the repair. When wear is in the valve body side or post side of the shift shaft, occasionally you can make a bushing to compensate for the wear (see article on “Chrysler RWD Valve Body Linkage Pivot Wear” by Gregg Nader in the tech resources area at sonnax.com), but more often than not, the fix is simply replacing the shaft. When alignment is as engineered, binds, codes and cable stretching become a thing of the past.

Randall Schroeder is a Sonnax technical sales and training specialist. He is a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of industry technical specialists, transmission rebuilders and Sonnax technicians.