The Transmission Digest Annual Survey of Retail Shops has served as benchmark and planning tool for the industry now for the past 38 years. Charts and tables in this study are based on a survey of subscribers that was conducted early this year.

Where differences are obvious, we separate the responses of transmission specialty shops from general repair shops that perform powertrain work in an attempt to create a more accurate picture of the information.

Conversely, when we depict more general information concerning the industry as represented by readership of the magazine, we combine the segments of transmission specialty and general repair shops. In most cases, the information is the result of calculating an arithmetic (or weighted arithmetic) mean of the answers we received.

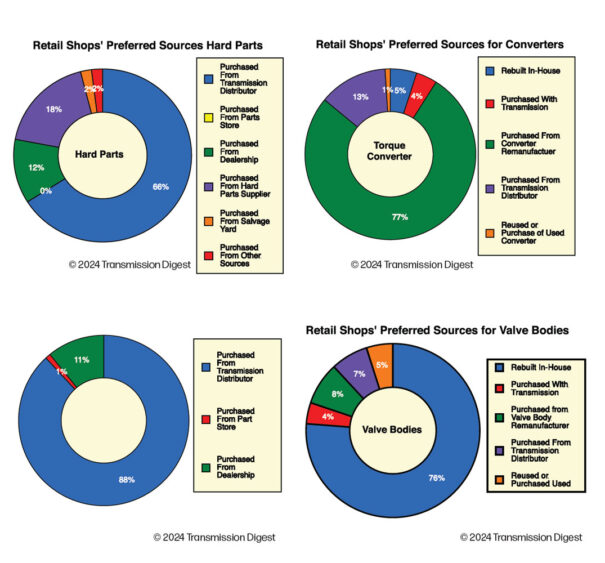

Who’s selling us parts/sub-assemblies?

One way of examining the shops that make up Transmission Digest’s readership is the survey question, “do you consider your shop to be a transmission specialty shop of a general repair shop?” In the past, there were marked differences between specialty and general repair shops as the former made use of a specialized channel of parts suppliers and distributors, while the later relied more often on traditional automotive parts stores, new car dealerships and jobbers.

Those differences have become much less apparent as transmission shops became general repair facilities while keeping their preference for obtaining parts and sub-assemblies from specialty distributors and parts suppliers. These days, those same specialty suppliers are available to the general repair shop that rebuilds transmissions.

To faithfully indicate the overall industry’s preference of supply sources, these figures were weighted based on the shop’s reported volume of transmission jobs.

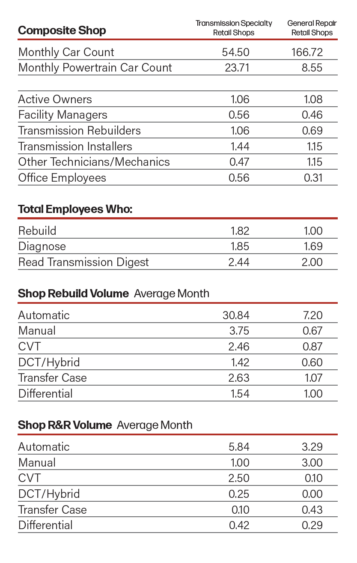

Composite analysis of Transmission Digest reader shops

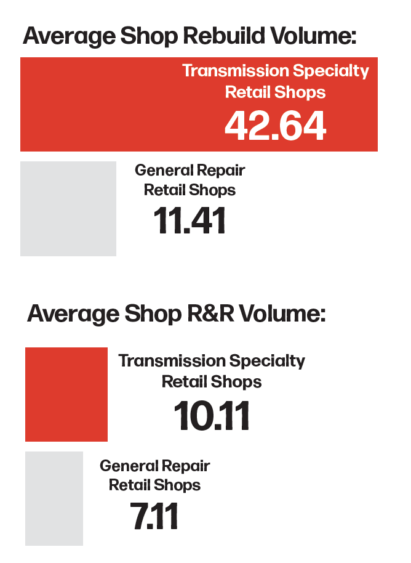

A revealing way of looking at the survey information is to create a composite shop, one that represents the mean average of all the information gathered for certain categories. In creating this composite, we look at self-described transmission specialty shops and general repair shops that perform transmission and related work.

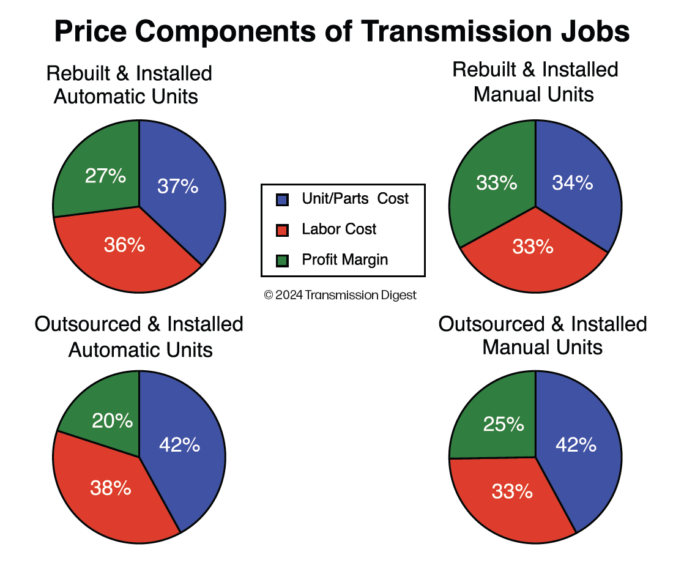

Labor + Parts + Profit = Price

This analysis is important for any business. It’s worth noting that many retail shops strategize without considering the cost of materials and labor in an effort to match the predominant local price for a particular rebuilt or R&R installed unit. This traditional approach of matching another facility’s price often results in adjusting the job’s profit component in order to reach the price point. Looking at all three of these components gives that shop a chance to explore for cost constraints in an effort to achieve profitability relating to a particular group of jobs.

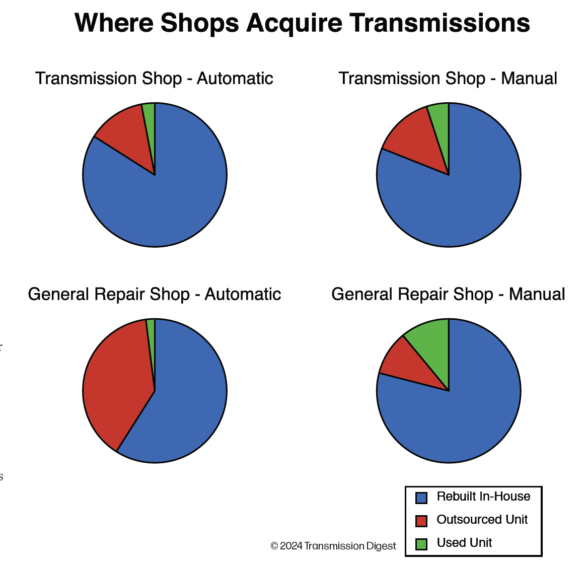

Sourcing transmission units

The survey identifies the percentage of units that shops installed used, rebuilt in-house as well as those that were outsourced. Outsourcing includes transmission units that are purchased from bench builders, automobile dealerships, aftermarket production rebuilders and reman units obtained from parts distributors. The charts here assume that the decision of a supplier for outsourced units is based on price, warranty, perceived quality and availability. We have combined all of the outsourced units into a single category for the graphic depictions.

We have added a weighting factor based on each shop’s report of monthly transmission job volume to accurately portray the overall retail market’s use of the various source categories. Finally, the pie charts depict the proportion of various unit sources used by those shops that offer the particular service named by the individual pies.

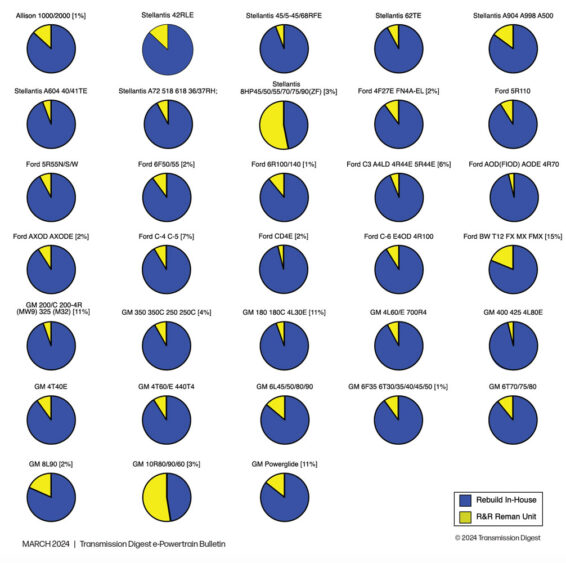

Rebuild it, perform an R&R or refer the job away?

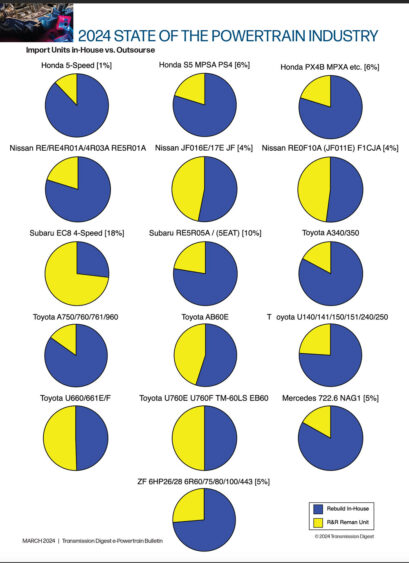

In this series of charts, we report on the transmission work that Transmission Digest subscriber shops perform. For each transmission family depicted, the shop was asked if most that unit was typically rebuilt in-house, replaced with an outsourced reman unit or if the job was referred to another shop.

We weighted the responses by the average monthly transmission jobs reported by each shop: A shop that works 100 transmission jobs a month is counted more heavily than the shop that handles one a week.

Because referrals end up in another shop represented in the survey, the pie charts show only the ratio of in-house rebuilt vs. outsourced reman units. The figures for percentage of referred jobs, when equal or greater to one percent, are in brackets next to the unit name. Historically, the rate of referral varies quite a bit from one year to the next based on the shop habits of responding subscribers.

Finally, the studied families of transmissions are based on kit sales. This year’s survey finds that 49 units/families make up roughly 96% of kit sales.

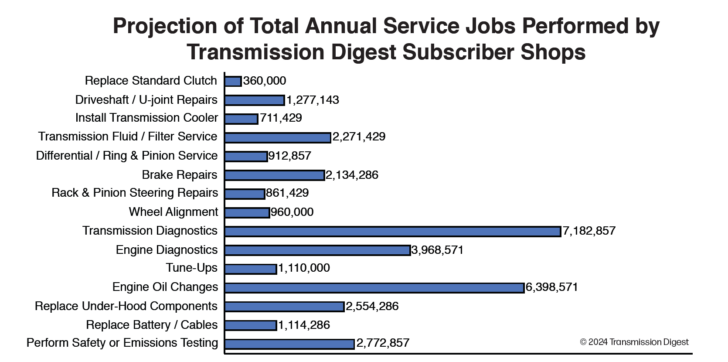

A look at what the industry does

There aren’t many measurements that impress the Transmission Digest editors more than a look at the total number of automotive jobs performed by our readership. Nowhere is the responsibility to maintain a widely varied and cutting-edge content emphasized more strongly to us.

The projected numbers of annual jobs were calculated by taking the average number of jobs for each category as reported by shops responding to the survey, multiplying by the number of retail shop recipients of the magazine and then multiplying by 12 to convert the monthly figure gathered in the survey question into annual projected jobs.

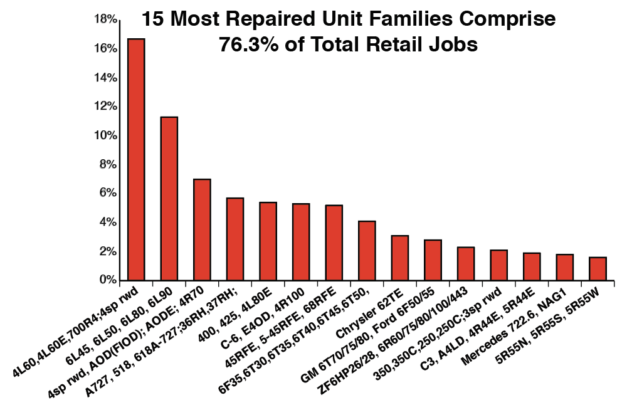

The industry’s most serviced units

For this year’s survey, we updated the list of most often seen transmissions and/or transmission families. There are 49 of these (based on distributor kit sales). This is an imperfect indicator as the reman factories often use kits specifically formulated for their operations as opposed to the distributor kits used for on-site rebuilding.

We approximate that these units make up just about 96% of the transmission jobs coming to the aftermarket. The 10 most common units accounted for 66.6%; the most common 15 account for 76.3% of all the work showing up in retail bays; while the 49 most popular units reflect 96% of transmission jobs.

While the venerable 4L60 transmissions remain the most often repaired, it is noted that six-speed units are increasingly being rebuilt/replaced. As the domestic pie charts indicate, eight-speed and 10-speed units are now commonly making their way to the shop bays as well.

Finally, there are a bountiful number of additional units that shops less commonly repair. For space consideration, these are not a part of the survey.