The complaint

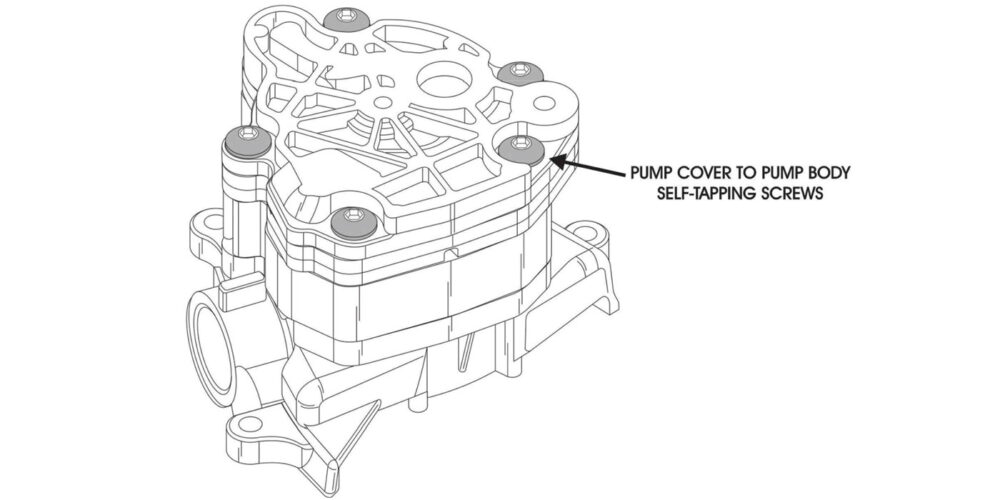

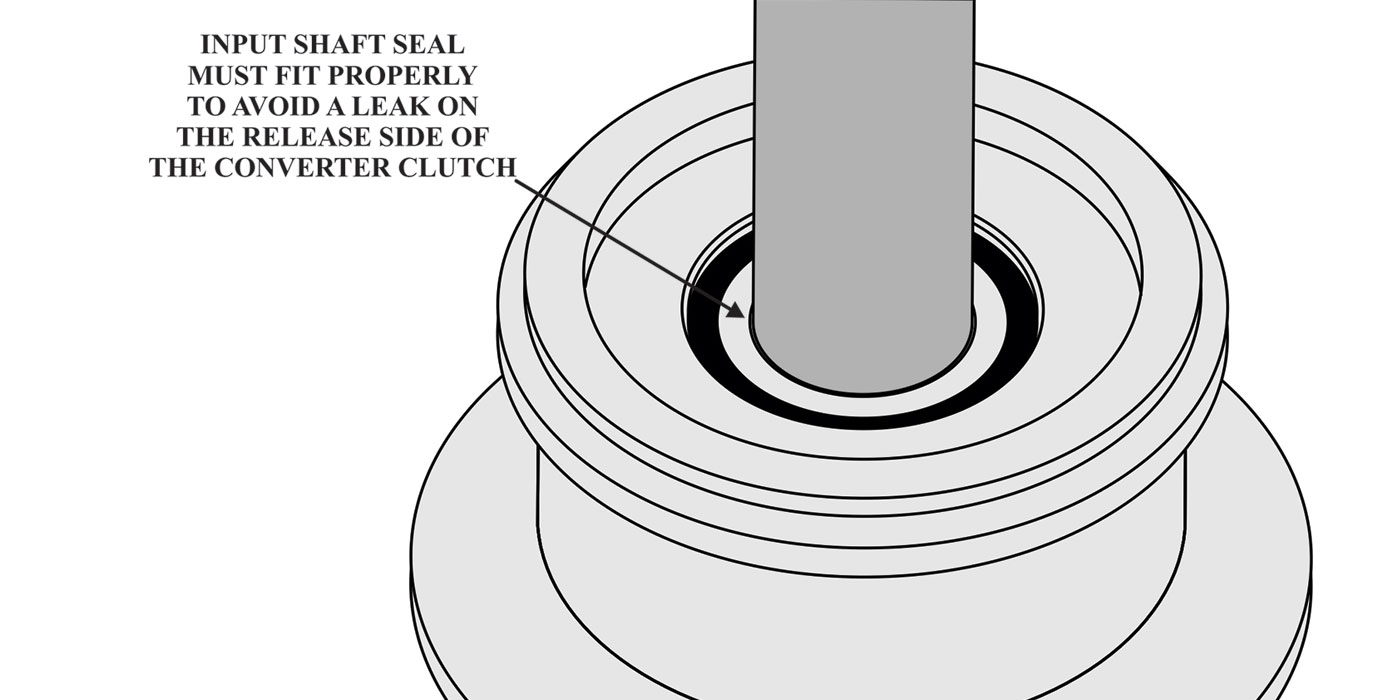

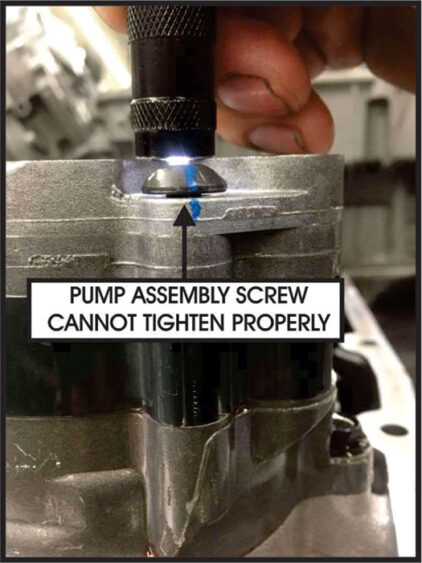

During the transmission rebuild process, the pump is disassembled for inspection and cleaning. When it is time to install the five pump assembly screws (see Figure 1, above), metal shavings are found in the five pump cover to pump body screw holes (see Figure 2) that will prevent the Torx head screws from tightening down properly, as seen in Figure 3. This will result in low pump pressure.

The cause

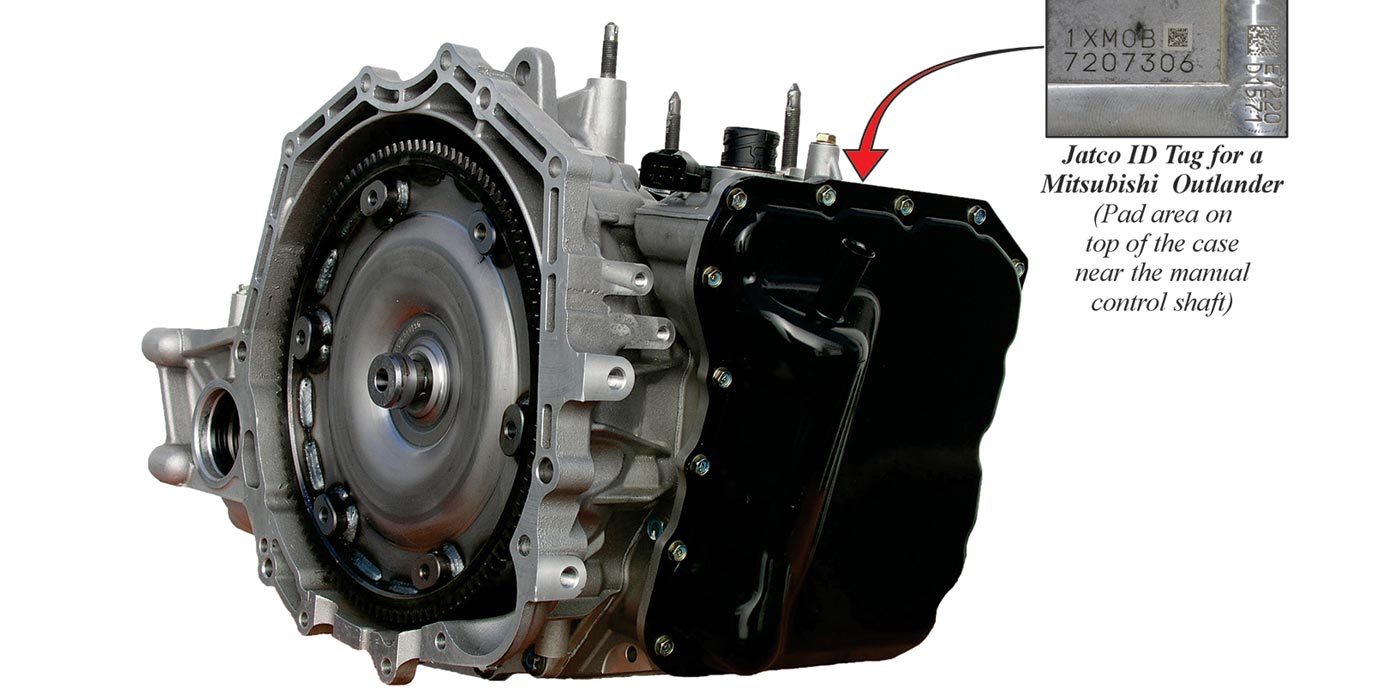

General Motors designed the 6T70/75 transmission fluid pump to be a non-serviceable component. The five Torx head screws that hold the pump sections together are self-tapping screws that cut their own threads into the pump body when assembled at the factory—you can see this in Figure 4. When the screws are removed, they are partially stripped, which creates the metal shavings.

The correction

Blow the metal shavings out of all five bolt holes, making certain all metal shavings are gone. Chase the threads with a M6x1.0 bottom tap—see figure 5—and clean the holes of any metal shavings. Install the five pump assembly bolts and torque to 120 in./lbs.

Read more articles in our Transmission Tech/Talk series here.