The complaint

A vehicle equipped with a GM 6T40 generation one transmission has just been overhauled. When the transmission was placed in reverse or drive, there was a significant delay. Overall transmission performance was poor. A line pressure check indicated that line pressure was low. The valve body and pump were ruled out as faulty components. The line pressure electronic control system performed normally.

The cause

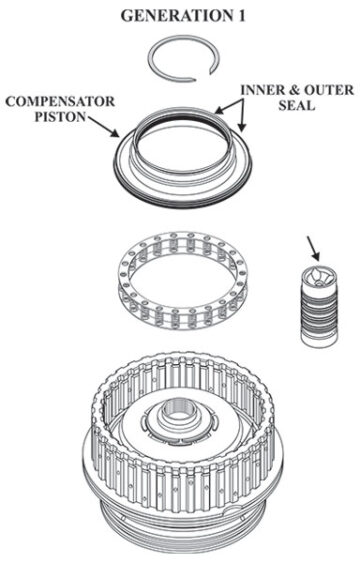

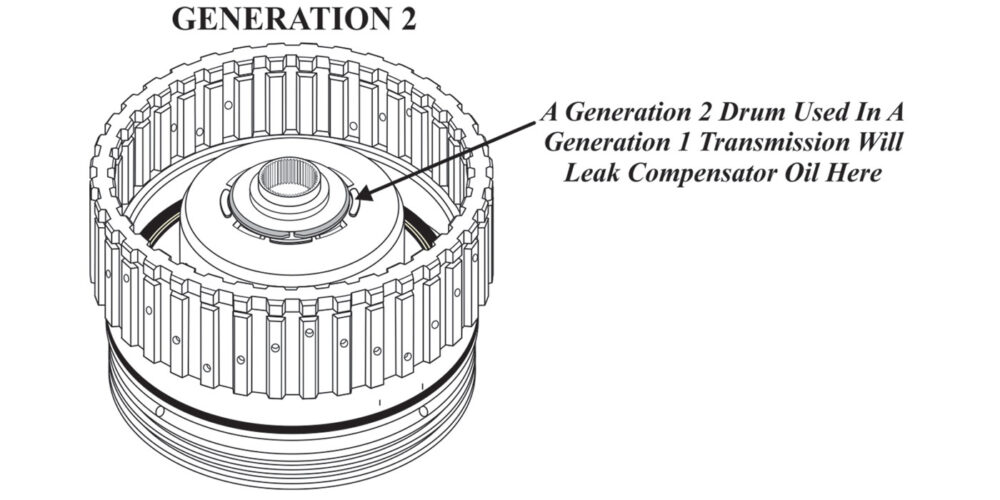

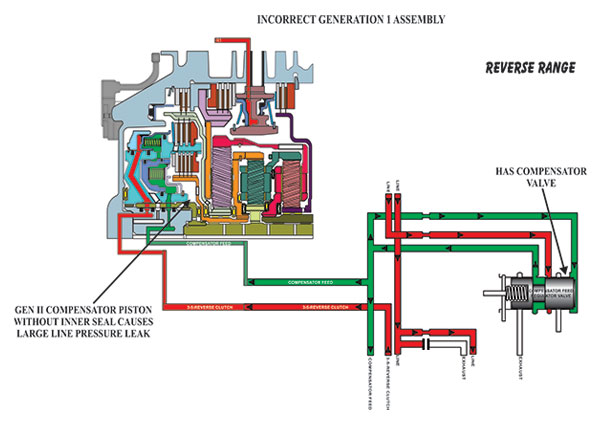

A generation two 4-5-6 Clutch Housing was installed in this transmission along with a three-ring support tower. The problem lies in the compensator piston that a generation two clutch housing uses compared to the generation one housing.

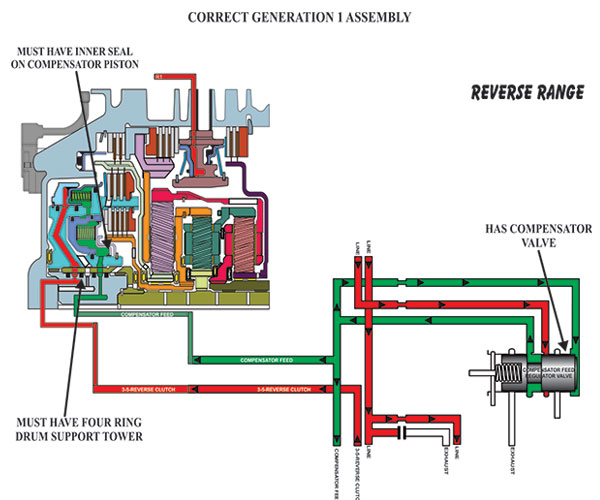

The generation one compensator piston seen in figure 1 has an inner and an outer lip seal. This is designed to seal regulated compensator oil. This requires a four-ring support tower.

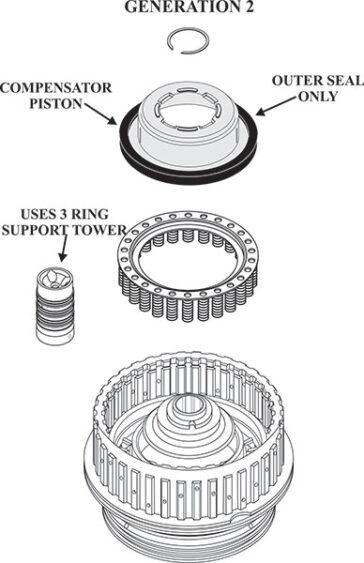

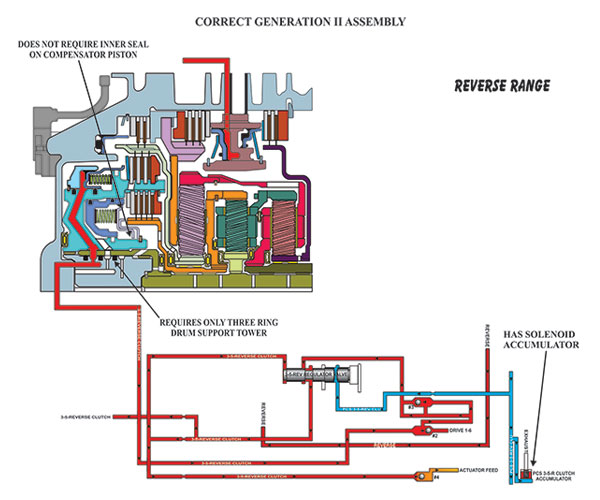

The Generation II compensator piston seen in figure 2 has only an outer lip seal. This requires a three-ring support tower.

In a generation two transmission there is no compensator circuit; it uses a backfill circuit instead. This is why the generation one transmission had the delay due to compensator oil leaking past the inner diameter of the compensator piston, as shown in figure 3.

In addition, loss of oil past the compensator piston causes a lack of sufficient pressure to fully stroke the compensator valve which allows line pressure to leak past the missing seal and ring, as seen in the hydraulic in figure 4. The compensator oil leak was significant enough to lower line pressure to the point that it affected overall transmission performance.

The correction

Install a generation one 4-5-6 Clutch Housing components and four-ring support tower in a generation one transmission.

Summary

Line pressure is fed to the Compensator Feed Regulator Valve, which then feeds the compensator feed circuit (green). Compensator oil enters between the top two rings on the four-ring support. This is why a four-ring tower is needed. The oil then seals on both the inner and outer seals on the piston.

When a Gen. 2 clutch housing is used, the compensator oil from the Gen. 1 valve body leaks at the top of the ring tower and at the piston due to a missing seal. This large leak closes the compensator regulator valve all the way trying to compensate for the leak. The result is that line pressure is fed into a huge leak lowering overall line pressure, which then affects all ranges. The transmission may even fall out of gear at a stop.

Note: The vehicle may perform normally on a road test as long as pump volume can overcome the leak. Once the pump can’t overcome the leak, the aforementioned complaints will occur.

The 3-5-Reverse pressure control solenoid routes clutch apply fluid to an accumulator valve. The accumulator valve is used to dampen any pressure irregularities occurring in the solenoid clutch fluid circuit. This helps to control clutch apply fluid pressure and feel. As a result the Gen. 1 compensator valve has been eliminated.

Read more articles in our Transmission Tech/Talk series here.