The complaint

A 2012 Chevrolet Cruze equipped with the generation one GM 6T40 transmission has the typical 3-5-Reverse snap ring blow out. The technician replaces the clutch housing with a new AC Delco part and goes on to complete the rebuild.

Upon completion of the transmission installation, the technician attempts to reset the shift adapts, but it will not relearn. He drives the car in an attempt to reset the adaptives even though the transmission is shifting poorly, at which time the “Check Engine” lamp comes on. He uses a scan tool to retrieve codes and a P0218 “Transmission Overtemp Condition” is set. The technician checks the transmission temperature on the scan tool data list, which indicates a temperature of 260ºF.

With the car back on the lift, the technician shoots the transmission pan with an infrared temperature gun, which indicates a transmission temperature of 250ºF. The infrared temperature gun was used to check the temperature of the cooler lines. There was a 30ºF difference, so the cooler was considered to be working properly.

The technician notices that the transmission temperature never rose with the engine running and the transmission in park. The moment the car was put into drive with the foot brake applied, the temperature immediately began to rise.

The pan was dropped and it was full of fine metal, which would indicate a converter failure. With the transmission cleaned out and another rebuilt converter installed, the same events took place on the road test with the same results.

When the transmission was removed the pump was disassembled to check the TCC Control Valve and it was fine. So were the front and rear stator bushings.

The cause

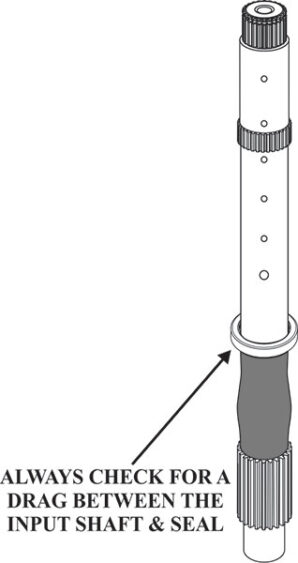

The technician slid the input shaft into the input shaft seal in the back of the pump cover and did not like the fit. There was practically no drag on the seal. The technician recalled the last 6T40 he had built and that seal had a drag on the input shaft. This means the converter clutch was applied just enough to drag but not enough to kill the engine. This would explain the overheat condition and the converter failure.

The correction

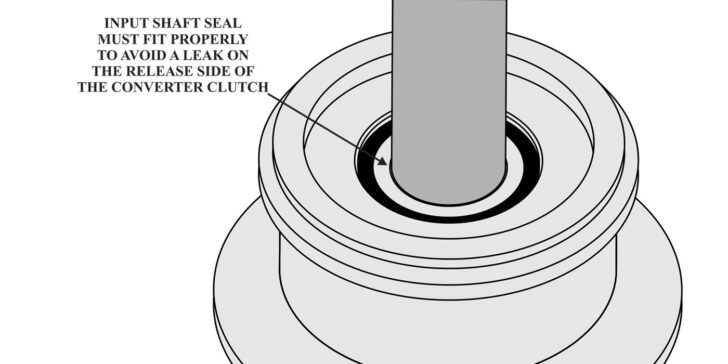

A new input shaft seal was installed and the fit to the input shaft was checked and it had a drag on the shaft. Always check the fit of the new seal on the input shaft for drag, as shown in figure 1.

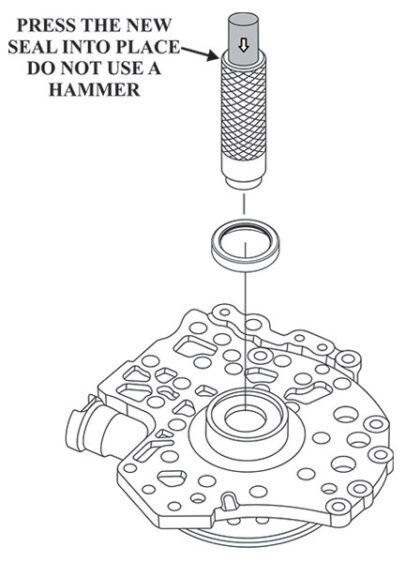

Press the new seal in place as shown in figure 2; do not use a hammer which could deform the seal causing the above complaints.

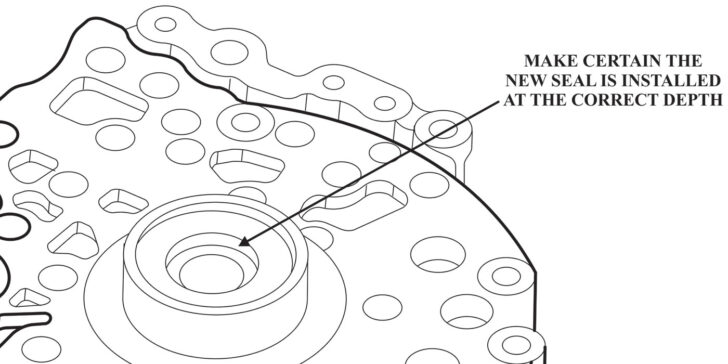

Note: Check the depth of the old seal before removal so the new seal is installed at the same depth as seen in figure 3.

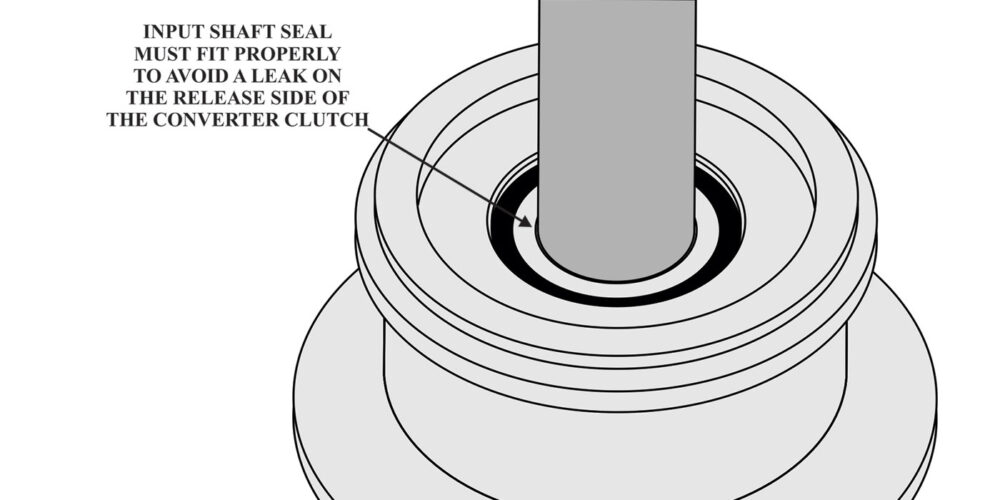

The input shaft seal must not be deformed in any way so it fits the input shaft properly to avoid a leak on the release side of the converter clutch, as seen in figure 4.

The transmission was assembled and installed back into the vehicle. The shift adapts reset immediately and the transmission temperature remained normal as well as transmission operation during the road test.

Read more articles in our Transmission Tech/Talk series here.