Continuously Variable Transmissions, or CVTs, are more common than you think. Audi, Subaru, Nissan, Ford, GM and many other automakers use CVT transmissions in cars and SUVs. There is no way to avoid them. Chances are there is one in your shop right now.

What does CVT mean for technicians? On the maintenance side, a CVT requires more or the same frequency of fluid and filter changes as a conventional automatic transmission, and many of the basic procedures are the same. On the diagnostic side, a CVT is less complicated internally than a six- or nine-speed transmission. Diagnostics with a scan tool are about the same. On the service side, while you may never pull a variator or belt out of a CVT, you can service components like sensors, pumps and valve bodies. The point here is not to fear a customer complaint about a CVT.

CVT identification

So how do you know you are working on a CVT? This is tricky, because a CVT is about the same size as an automatic transmission. The only indication might be the shape of the case. In some CVT-equipped vehicles, the shifter might lack a low range. But, some CVTs might have a sport mode or even paddle shifters. Otherwise, you may never know you are driving a CVT.

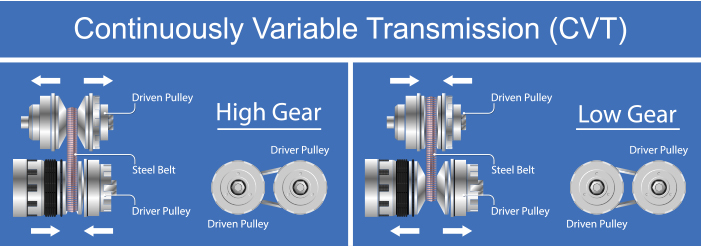

A CVT does not have conventional forward gears. Instead of five or six forward speeds, a CVT has a single belt or chain attached to two pulleys that vary the diameter to change gear ratios. This allows the engine’s input to operate at a constant RPM range while the output speed of the transmission changes. Think of it as having an infinite number of gears that can be selected for any situation.

There is nothing magic about a CVT, but there are some unique diagnostic, service and inspection procedures that need to be followed.

CVT operation

On many vehicles, there is a torque converter where the CVT attaches to the flex plate. Some vehicles use a torque dampening disc or even a clutch that resembles the one you might find on a manual transmission vehicle. Disc and clutches are more common on CVTs found in hybrids.

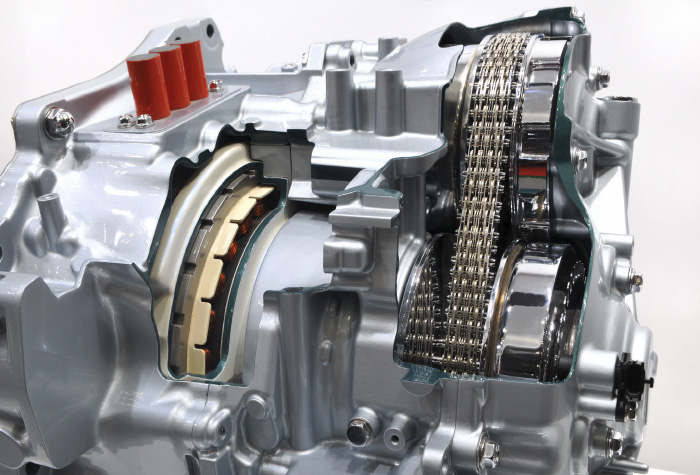

Behind the torque converter or discs might be a pump. This is very similar to a conventional automatic transmission pump. But, on many CVTs, considerably more pressure is generated than a conventional automatic transmission pump. For example, some CVTs create more than 700 PSI. Some pumps are powered by the input shaft. Others might be external and powered with a chain, like on some Jatco and Aisin transmissions.

There are typically two clutches next on the input shaft that lock sun and planetary gears. These clutches are used to engage forward or reverse. Now we have the conical pulleys or variators, the heart of the CVT. These have a groove that the belt or chain rides in. The two conical plates of the variator are angled. As the plates’ distance decreases, the belt or chain is forced outward. This changes the diameter of the variator.

Connected to the input variator via the chain or belt is the output variator that does the same trick as the input variator. On some transmissions, the input variator is called a primary variator.

The position of the variators is controlled by hydraulic pressure generated by the pump and controlled by the valve body. The base of the variator is a hydraulic chamber that controls the position of the conical plates. This arrangement is why the pump has to produce so much pressure.

With the input variator open and the output variator closed, we get low gear where the input shaft or variator has to spin several times to turn the output variator once. This multiplies torque and gets the vehicle moving from a stop.

When you reverse the variator positions, with the input variator closed and the out variator open, we get overdrive where one turn of the input equals three-quarters of a turn of the output shaft.

A CVT will change the position of the input and output variators to give an infinite number of gear ratios. This allows the engine to remain in the powerband where it is the most efficient.

The belt or chain can have more than 400 parts. There are more than 300 of these plates or “elements” that grip the plates of the variators. The elements are held together using steel bands on either side. This type of belt pushes the output cog.

A chain is typically used on larger vehicles with more weight and power. These pull and work as a timing chain. During normal operation, the chain or belt will shed some metal debris that you might see on the magnets on the filter. The fluid path through the transmission is designed to keep this debris out of the valve body.

On the output shaft, the power is transferred to the final drive and differential on this transmission. On some CVT transmissions, the output could be attached to a start clutch. The start clutch connects the transmission to the final drive. The clutch is controlled by the valve body. This is common on some Honda and Toyota CVT transmissions.

As you see, inside the case of a CVT is not anything too exotic or complicated. Next, we will cover diagnostics and some service tips.

Shifting a CVT

If a transmission doesn’t have any gears, how do you know it is shifting smoothly or slipping? The answer is to not go on feel or compare it to an automatic transmission. The secret is to trust your scan tool more than the test drive.

A CVT has a multitude of sensors inside and on the case. These sensors measure the speed of the variators, positions of the stepper motors, solenoids, along with temperatures and pressures data. The control system works hand-in-hand with the engine control module to ensure the gear ratio is correct for the load and speed.

Think about a slipping transmission. When you are test-driving a vehicle, the slipping of the transmission can be felt as a flare of engine rpm and the lack of acceleration.

Ask yourself, how does the transmission control module sense slipping of a CVT? If the problem is a slipping belt or chain, it will look at engine RPM and the speed sensors on the input and output variators.

The transmission control module knows the commanded position of the variators. If the chain or belt slips, the speed of the input will not match the expected speed of the output variator. This discrepancy would cause the transmission control module to set a code. Some codes will use the words “plausibility error” in the code descriptions when these problems occur.

The same is true with a shudder in the transmission. The transmission control module will look at the crankshaft position and its sensor on the input and output pulleys. It will also look at the actions of the solenoids to decide to adjust shifts or set a code. Think of it as a misfire monitor for shifts.

Plausibility error codes can also be set if the forward or reverse clutches do not perform as expected. The torque converter lock-up clutch can also set plausibility codes. Plausibility codes can be a sudden engagement of the clutches because there are multiple sensors that detect the rotational speeds of the inputs and outputs.

As for codes, you will notice that sequence of letters and numbers start with “P,” indicating a powertrain code and have a 1, 2 or other numbers next. These numbers indicate it is a proprietary code that is typically unique to the manufacturer and the CVT transmission. Some codes might have letters in the third or fourth position. To decipher these codes, you will need service information or a scan tool with the correct software to interpret the name of the code.

Some CVTs will use a stepper motor to actuate a valve that controls pressure to the primary variator. The stepper motor connects to a ratio control arm and ratio control valve. The other end of the ratio control arm connects to the pulley follower.

The ratio control valve changes the transmission ratio by changing the pressure in the pulleys. The transmission control module sends a signal to the stepper motor in a specific pattern. The stepper motor can extend or retract, moving the position of the ratio control valve.

The transmission control module knows that the stepper motor is functioning by the changes in the speed of the two variators. So when it sees a ratio issue, it blames the stepper motor and sets a stepper motor code like P1778. But it is not grounds for replacement unless you have checked the hydraulics it controls.

This article was originally published by our sister site, Brake & Front End.