Shift Pointers

- Subject: Failure of C1/K1 clutch

- Units: Aisin Warner AWF21 (TF-81SC), TF60-SN (09G/09K/09M)

- Vehicle Applications: Ford 500, Audi/VW

- Essential Reading: Rebuilder, Diagnostician

- Author: Wayne Colonna, ATSG, Transmission Digest Technical Editor

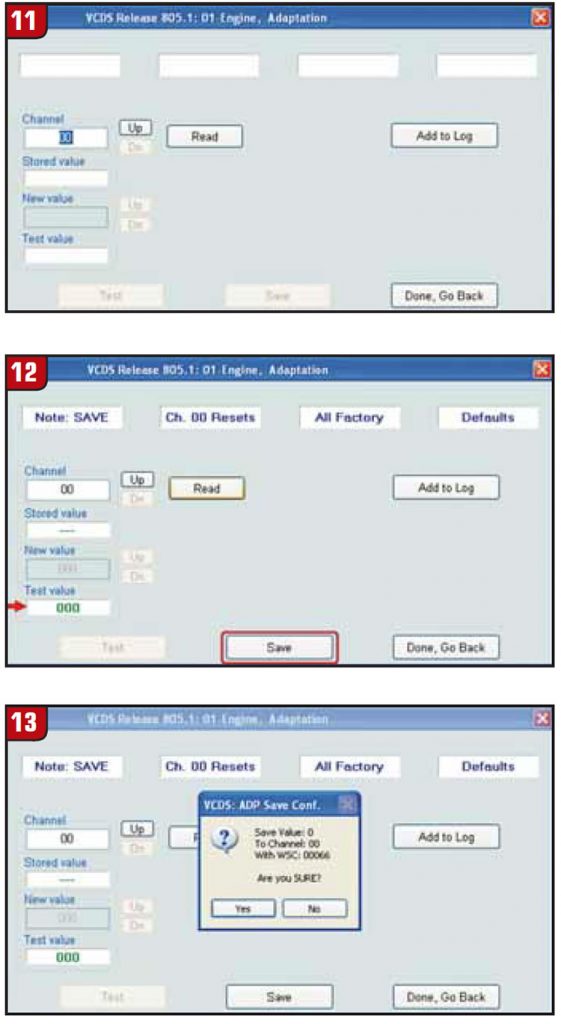

If you just read the “Technically Speaking” article in this edition of Transmission Digest you might recall that we spoke a little about how balance pistons are being used in rotational clutch drums, and their purposes. This article covers one of the problems we have seen with the C1/K1 clutch (Figure 1) as it relates to the AWF21 (Aisin TF-81SC, used in the Ford 500) and the TF60-SN (09G/K/M, used in Mini Cooper, Audi/VW) transmissions.

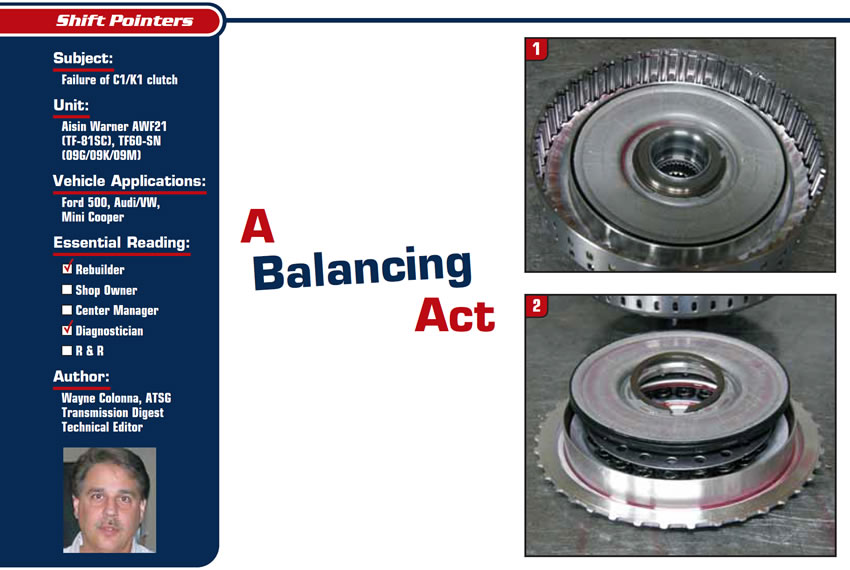

Figure 2 shows the balance piston sitting on top of the clutch-apply piston. You will notice that this style of balance piston has a molded seal on only the outside diameter. There is not one on the inner diameter. This may remind you of a similar piston in the 41TE transmission. The idea with the 41TE is to keep the double-action overdrive/reverse-clutch piston centered when not in use.

Residual oil behind the apply piston is neutralized by the oil supplied to the balance piston, known as the dribbler circuit. So this type of technology has been with us since as early as 1989.

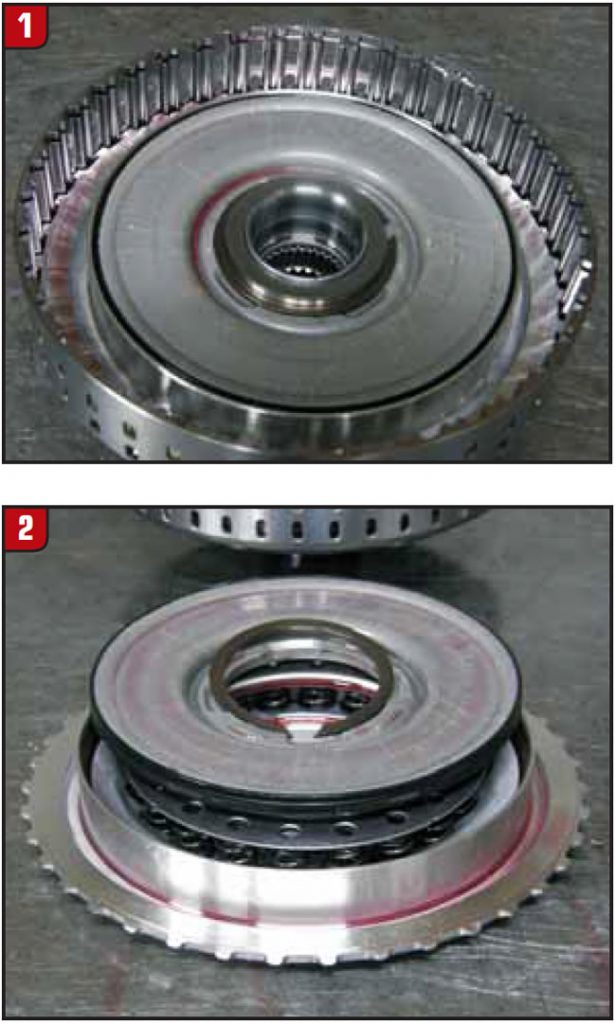

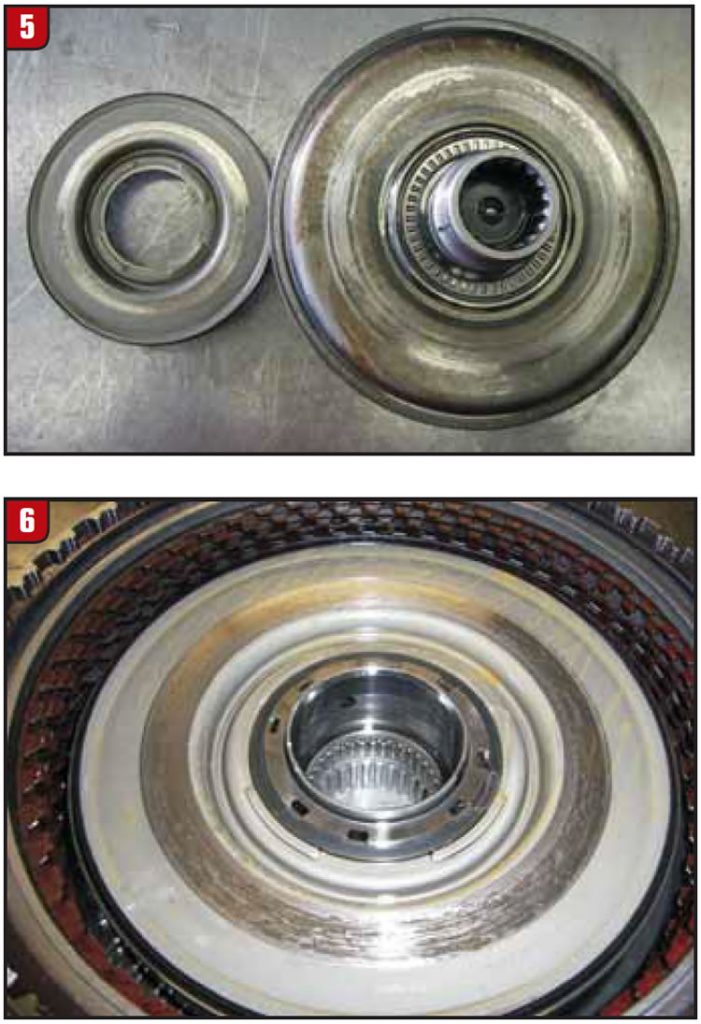

Getting back to the problem we have seen with the six-speed TF60-SN unit, the original-design drum in a transmission known as the AF40-6 (similar to the one in the Ford 500) had center slots in the drum (Figure 3) and the apply piston was solid metal (Figure 4). When this drum was fully assembled and placed into the transmission, a needle-bearing race was placed on the drum, covering the center slots in the drum. Sitting in front of this clutch-drum assembly is the front planetary assembly’s internal ring gear, which has the needle bearing that rides on this race. When the vehicle is being driven, the C1/K1-clutch drum rotates with the front planetary assembly’s internal ring gear 1-1 in first through fourth. But when the clutch is released in fifth and sixth the clutch drum and ring gear rotate at different speeds.

Now here is where the problem begins: With the slots being covered by the needle-bearing race on the C1/K1 drum, the oil behind the balance piston cannot exhaust sufficiently past the slots in the drum with the bearing race over the top. When the apply piston comes on during a 6-4 or 5-4 downshift, the oil between the apply piston and balance piston causes the balance piston to flex forward, pushing it into the backside of the internal ring. Since these two parts are temporarily turning at different speeds they rub together, and the metal-to-metal contact causes damage (figures 5 and 6).

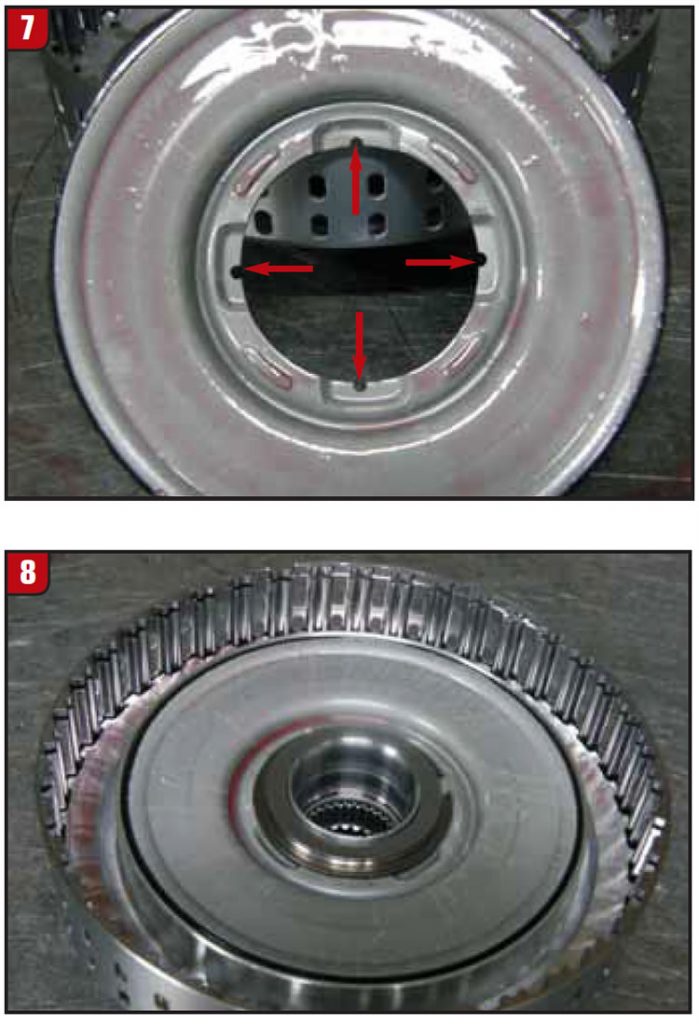

Through the years the drum, apply piston and counterbalance piston have had moderate changes made to them in an attempt to correct this condition. Despite these changes the problem persists. What we are doing now, which seems to be working well, is to use a Dremel tool and make little notches around the inner diameter of the balance piston (Figure 7).

Do not overdo it, as too much will cause a new problem for you. If you look at the area where the notches are placed you will see one of the modifications made by the manufacturer. They made recesses in the piston so that this oil could have an exhaust. They also eliminated the slots from the drum (Figure 8). However, with the snap ring sitting over the top of these recessed slots in the balance piston, the exhaust made by these slots must not be sufficient to alleviate the problem, as the failure continues. So by adding just a little help with a Dremel, the problem is solved.

There is yet one more item to cover, and that is to reset shift adapts after any type of repair. This is a must-do procedure; otherwise, you will experience harsh and/or flared shifts after overhaul and you may think you have a problem when you really do not.

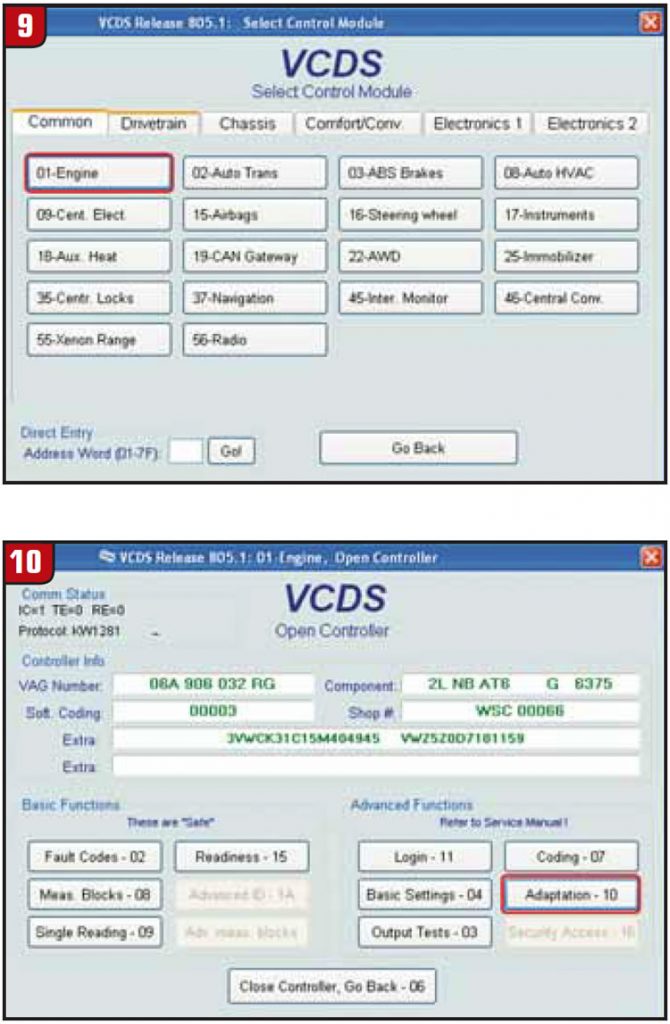

The problem in setting the shift adapts is in having a tool that will accomplish the task. The VAG-COM does, and it does it easily. To do the reset you must go into the ECM, not the TCM (Figure 9).

There you will find the adaptation menu (Figure 10). When you are there select the “Read” button (Figure 11) and a “000” will show up in the “Test value” window; then, select “Save” (Figure 12). The next screen will ask you whether you are sure, and you select Yes and you are finished (Figure 13). Now drive the vehicle, and in a few drive cycles the transmission should shift well if there are no real problems. No doubt, it’s all a balancing act.