Technically Speaking

- Author: Mike Riley, Technical Editor

- Subject Matter: Valve body

- Unit: TF60SN (09G)

- Vehicle Application: Volkswagen

- Issue: Shift complaints

It’s all about the valve body

Almost every transmission family ever produced has had weak spots or difficult areas to deal with, whether it is operation, diagnosis or assembly. The Volkswagen TF60SN (Aisin produced) is no exception.

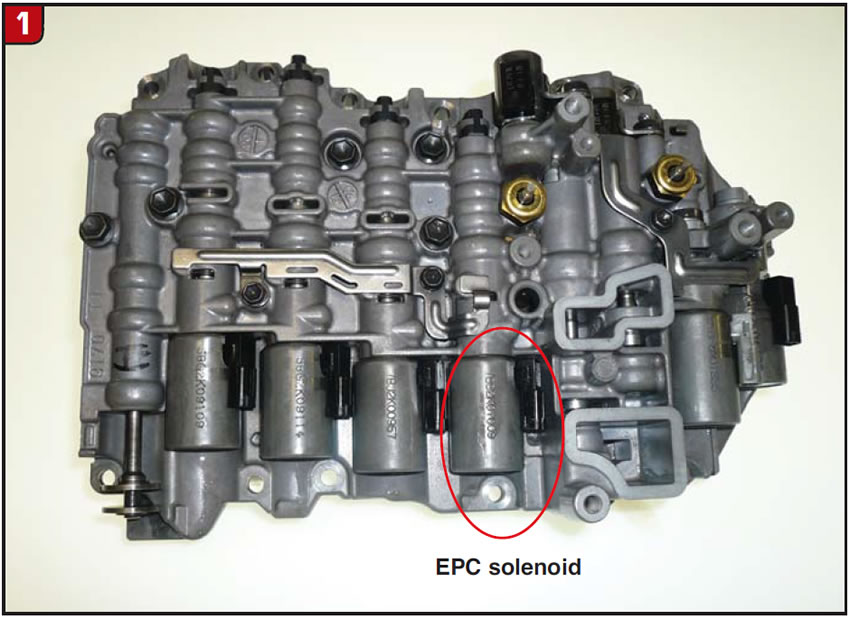

One area of the TF60SN (09G) that has surfaced as troublesome is the valve body. In addition to the normal valve-body issues is the electrical concern. Today’s valve bodies not only have a ton of electrical do-dads to deal with, but the complexity of the items has also increased (Figure 1).

The majority of the solenoids on the TF60SN valve body are linear, which means not only are they PWM function but they use valves as well. The valves ride in bushings that can wear and create a multitude of problems.

The valve body itself is no walk in the park either. The location and extent of wear will determine the types of problems that occur, just as with any other valve body.

The TF60SN, however, takes this to new heights. Older valve bodies were pretty basic, using simple shift valves, checkballs and orifices to control upshifts and downshifts. A pressure regulator along with boost valves would control line pressure, and accumulator valves would help to control shift quality. Even with the increase of electrical components such as solenoids, pressure switches and sensors, operation remained fairly simple. Newer valve bodies such as in the TF60SN literally use a solenoid and regulator valve for every clutch as well as main line-pressure regulation and other functions.

Computer controls have also advanced and are able to fine-tune shift timing and shift quality. On vehicles like Volkswagen, a designated scanner program is required to tap into computer commands to the transmission. The VAG program can access most of the TF60SN functions, with the exception of line-pressure control. A laptop computer can be used to access the VAG program, which would then function like a regular handheld scanner for road testing.

The TF60SN valve body consists of four main chunks of housings. The lower housing (Figure 2) contains the six linear and two shift solenoids along with several valves.

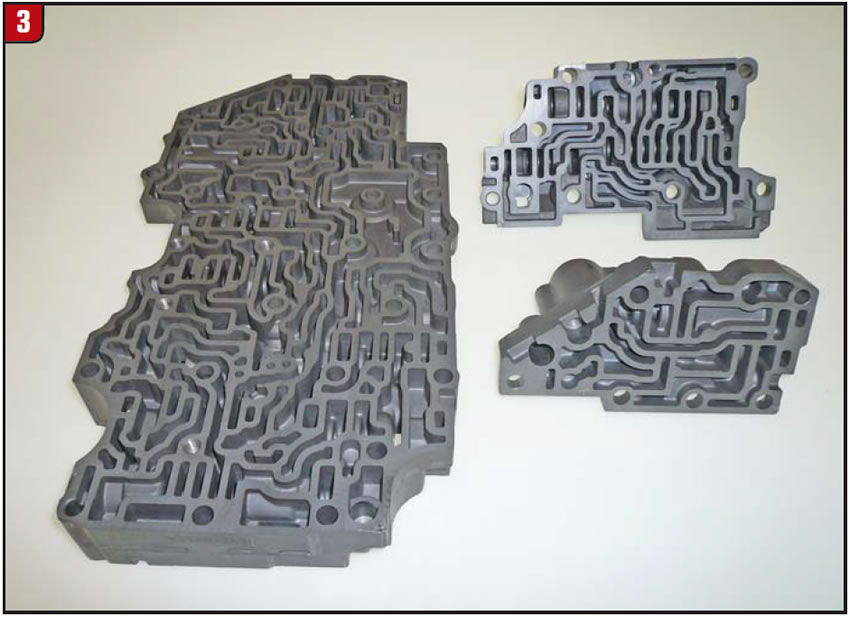

The other housings are the upper, and the small and large accumulator housings (Figure 3). Collectively, there are enough valves, springs, clips, checkballs and spring-loaded checkvalves to outfit three valve bodies.

The valve body shown in this article was removed from a 2003 Volkswagen Beetle with 82,000 miles on it. Cold, the transmission worked well. Garage shifts, upshifts and downshifts were all normal – until it got hot, that is. Once the temperature reached about 70° Celsius, it got ugly quickly. The shifts went from mild mannered to super-hard in a heartbeat. The neutral-to-drive apply actually had a double bump occur about three to five seconds apart, almost as if the K1 clutch applied twice.

There were no trouble codes set and all computer signals seemed normal using the VAG program. One key computer signal that is not available on VAG is line pressure, and since all clutch apply was affected, having access to it would have been nice. The symptom resembled a stuck regulator valve or EPC solenoid that would act up once hot.

The valve body was replaced with a reman and the unit worked well, cold and hot. The question then became, “What’s wrong with the original?” Since the problem could have been either electrical or mechanical, the solenoids were inspected first. Although the EPC was the main focus, all the linears were checked for resistance and amperage as well as valve movement. They all appeared to be OK.

Note: A tool such as the Schaffer solenoid tester can be used to cycle the linears to verify valve movement. Additional fixtures would be needed for pressure testing.

The valve body was then disassembled to look for stuck or worn valves. Using a pick to move the valves showed they were free in their bores. All the valves and sleeves were removed and inspected for wear. All valves were in good condition as illustrated in the sampling in Figure 4.

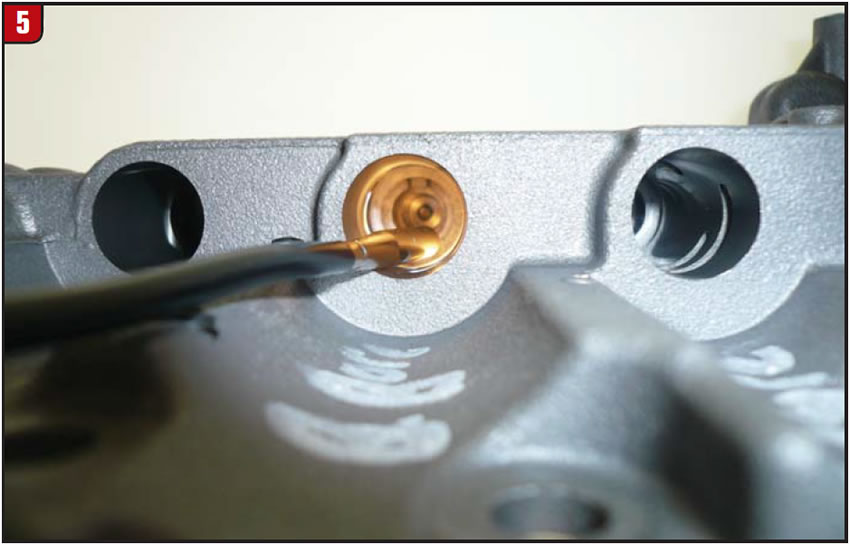

With a bore flashlight, each bore was inspected for wear (Figure 5). All bores appeared to be in good condition, with no scratches or egg-shaped bores. After the preliminary inspection was completed, all valves were reinstalled and the valve body was reassembled. At this point, there was nothing obvious to explain the hard shifting.

The valve body was sent to the folks at VBX (ValveBody Xpress) to perform a thorough test and inspection. What had occurred in the vehicle also occurred on their test stand. Cold, the clutch pressures were good, but as the temperature was raised, pressures started to drop off.

Normally, falling pressure would result in softer clutch apply, but not with the TF60SN. As with other, later-model applications, when the computer detects pressure changes from the norm, it will compensate accordingly – in this case, overcompensate.

The technicians at VBX have experienced this type of problem and have taken steps to rectify it. Although it’s uncommon, the solenoids functioned fairly well so the valve body was again disassembled and all valves were removed. Valve-body remanufacturers use different methods to determine the integrity of valve bores (gauges, vacuum test etc.).

Upon inspection, several bores were found to have varying degrees of wear, which would explain the fall-off in pressure. The computer knee-jerk reaction was the result.

Due to the complexity of the TF60SN valve body, VBX, among others, is required to do an inordinate amount of work to restore the valve body and make it function correctly.

It is in the DNA of a rebuilder to “fix” stuff on the bench, but in some cases like the TF60SN valve body, the effort may exceed the benefit.