After rebuilding a 5R110W trans for a 2009 F350, the vehicle was road tested and then delivered to the customer. While driving the vehicle, the customer noticed that the transmission temperature in the information center went to 250 °F (figure 1).

When it was returned to the shop the wrench light was on (figure 2). A scan tool pulled DTC P0218 for a Transmission Overtemperature Condition confirming the customer’s observation. The next morning the tech cleared the code and took the vehicle out for a road test. The overtemperature condition did not appear. He drove the vehicle for over an hour watching the transmission temperature in the information center which never went beyond normal.

The shop then called the customer to inquire about the exact conditions he was driving the vehicle for the over-temp to occur. This revealed that the vehicle had to be driven on a highway at 55mph or greater. With this new information, the tech drives it on the highway at 55 plus mph where he watched the temperature run up to 250 °F followed by the illumination of the wrench light. When he returned to the shop, a laser gun was used to check the temperature of the oil pan sump. It showed 240 °F confirming an overheating condition did exist.

Cooler flow was then checked by carefully disconnecting the return line at the transmission. Very little flow occurred. This was not an original problem with the transmission and during the rebuilding process, the only hard part change made was the pump and torque converter. For this reason, the unit was pulled to inspect the pump.

There is an early and a late style pump for the 5R110W transmission. 2003/2004 for early and 2005 and up for late. Mismatching these parts have caused a no-move condition along with seeing approximately 150 psi of line. Could there be another type of mismatch causing this overheating problem? Or possibly an early pump was installed into this transmission?

Converter Anti Drain-Back Valve

Once the pump was removed for inspection, it was confirmed that the correct year pump was used with all matching parts. Additionally, all the valves were moving, none were stuck. With nothing appearing to be wrong visually with the pump, the torque converter becomes suspect.

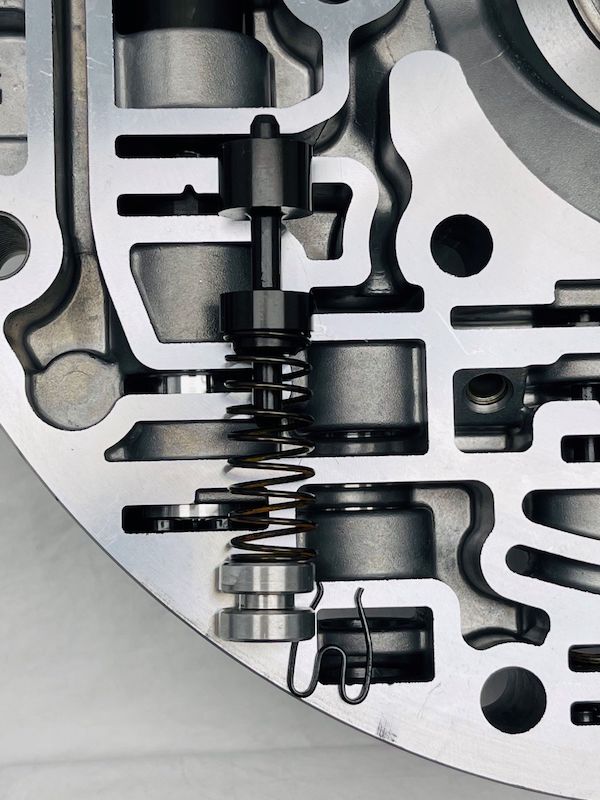

Figure 4

Figure 5

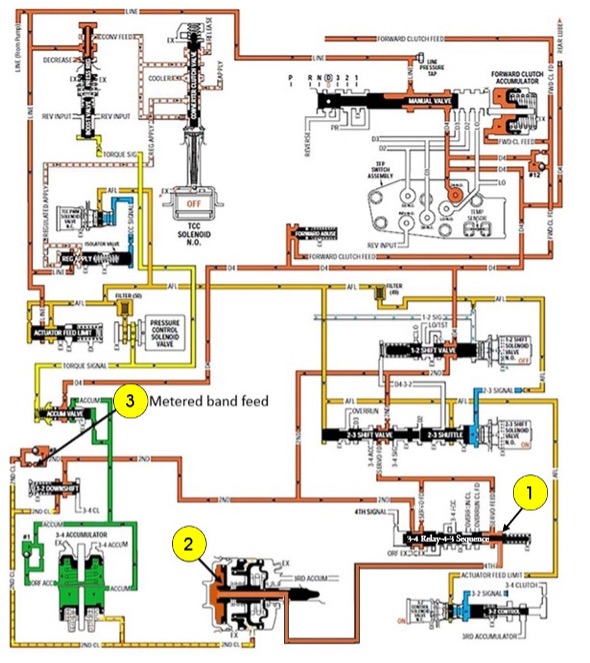

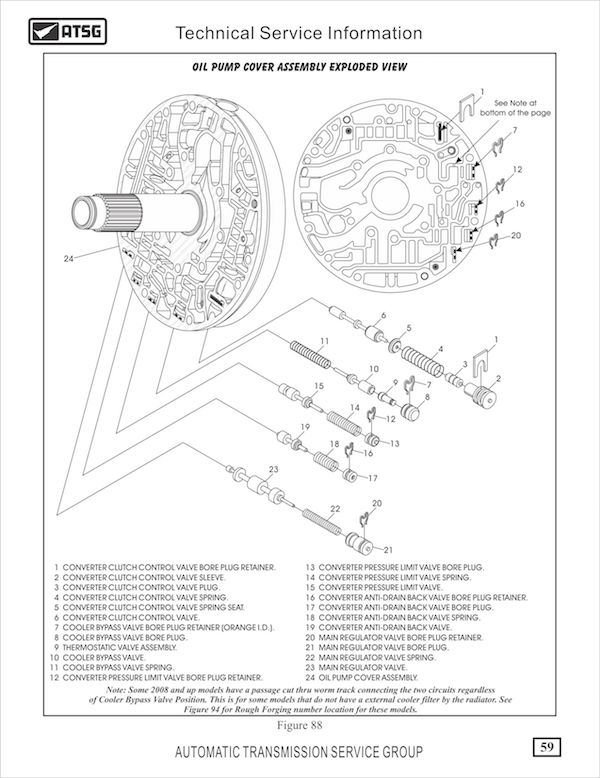

While this is being considered, an ATSG manual was used to verify valve configuration in the pump (figure 3). This extra step in the diagnostics revealed that the Converter Anti Drain-Back Valve was installed backward.

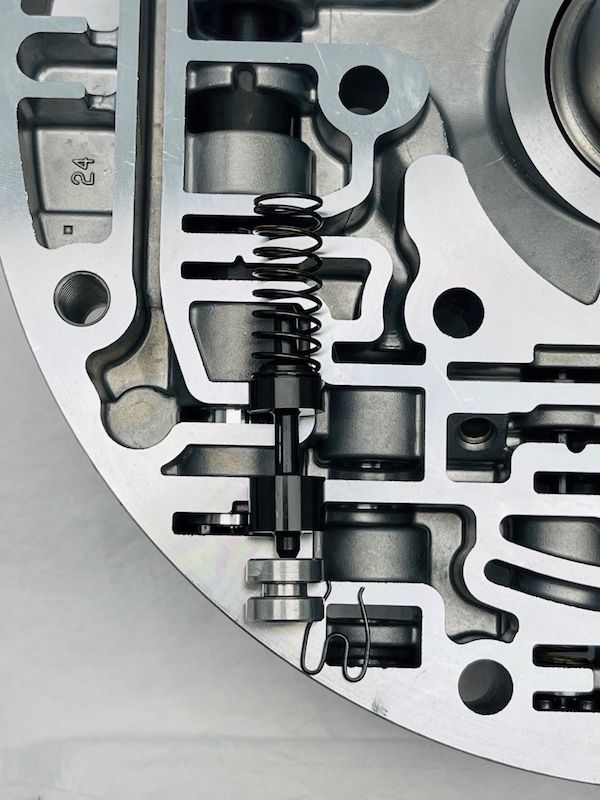

Figures 4 and 5 show the incorrect positioning of this valve lineup. Figures 6 and 7 show the correct lineup. The valve must be the first to be installed followed by the spring, bore plug and retainer.

With both valve lands (spools) are the same diameter, this is a very easy mistake to make. And it certainly is not a pleasant one seeing that it requires removing the transmission again from the vehicle. It could cause someone to experience hyperthermia themselves.

Figure 6

Figure 7