If a transmission starts overheating, the root cause must be something to do with the transmission itself, right? Not always. The following are a few examples where the transmission was not to blame.

Exhibit A: GM 6L80/90

The first overheating case comes from GM 6L80 and 6L90 transmissions equipped with a thermal bypass valve in the cooler lines.

The purpose of the thermal valve is to get the transmission fluid up to temperature when it is cold. I think if the valve were to fail in the open position no one would ever know the difference, but when it sticks in the closed position the vehicle lets you know quickly. I first heard about this problem from our warranty department, as they had been receiving calls about overheating transmissions. The cooler lines on these trucks do have a very high failure rate because they tend to leak where the rubber hoses are crimped to the steel lines, so our retail locations reported that they were replacing a lot of them. We have barrels of them in the scrap iron collection in the back of the shop.

Our technical department send out a request to collect the thermal blocks and send them down so they could be inspected. We at the Millard location in Omaha inspected some as well, and found that some of them have a plastic cup washer between the thermal valve spring and the thermal valve and some have metal cup washers. The plastic ones were getting a hole punched in them from the point of the thermal valve. Figure 1 shows the metal cup and broken plastic cup.

At first, our only fix was a new thermal block or rebuilding the blocks with metal washers. But now there is an aftermarket bypass that makes a spool valve that completely bypasses the thermal valve. Figure 2 shows the layout of a disassembled thermal valve with the broken plastic cup.

Figure 3 shows the aftermarket bypass valve that we now include with our remanufactured 6L80/90 transmissions.

We have also found the same setup on GM 8L90 transmissions that also have the same failure of the plastic spring cup. Figure 4 shows a recent 8L90 application that was overheating.

We have discovered that the OEM cooler lines for some applications went on national backorder recently, so we had to use some lines sourced from Dorman. One shop reported that our new bypass valve would not fit into a Dorman line, so they just left the lines as they were and used the bypass that came with the aftermarket lines.

Read more stories in our R&R Tech series here.

Exhibit B: Ford 6R140

Next, let’s take a look at 2011 and up Ford trucks equipped with 6.7L diesel engines and 6R140 transmissions.

In this situation, a customer dropped off their truck, saying that the transmission was getting hot. After a 15-mile drive on a summer day, the transmission temperature rose to 270°F very quickly. I had to pull over and let it sit for a while to cool down before I could go back to the shop. The transmission cooling system in these models is different than most that we are used to seeing; it has a secondary cooling system separate from the main engine cooling system.

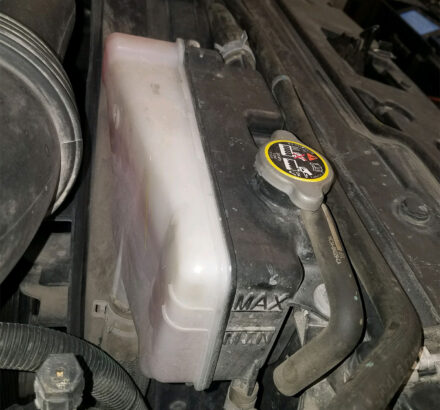

The secondary system consists of quite a few components: a transmission cooler, coolant pump, exhaust gas recirculation cooler, fuel cooler and a water-to-air intercooler for the turbocharger. It also has a small coolant tank for the coolant, which in this case was empty. Figure 5 shows an example of this tank.

With no coolant to cool the transmission cooler, the cause of the transmission overheating in this truck was evident. The truck looked like it had some recent engine work done. Several of the hoses on the top were not secured in their hold-downs and fasteners. For this reason, the steel coolant pipe that runs in line with the valve cover had vibrated and rubbed a hole in it, this made the coolant leak out causing the overheating problem. We then fixed the cooling system and got it to hold pressure. We then checked it out after a long road test and the transmission operation and temperature were back to normal.

Exhibit C: FCA AS69

This final case involves a Ram 5500 ambulance equipped with an AS69 transmission. The instrumentation indicated a transmission overheating condition. I took it for a long drive and at 239°F the heads-up display on the dash displayed a transmission over-temperature warning. I went back to the shop and used a temperature gun to narrow down where the problem was.

It was a hot summer day so everything from the transmission to the thermal block to the radiator was 190 to 200 degrees. It was hard to tell where the problem was.

I took off the upper cooler line at the radiator to check the flow and had none. I then took off the lines at the thermal block and still had nothing. The temperature on the scanner said it was 215°F inside the transmission. According to the specifications, the block is supposed to open at 160°F. This block is non-serviceable, so I had to get a new thermal block to replace it. After replacing the block everything was back to normal and working well. Since then, there a few different aftermarket companies that have come out with new thermal blocks that have no thermal valves in them and have full cooler flow all the time. (See Figure 6).

Given the frequency of failures surrounding these bypass valves and the emerging aftermarket replacement choices, it’s clear that the OEM needs to better address these critical areas of the transmission cooling systems they design. As we all know, heat is the enemy of these complex, modern-day transmissions.

Mike Greer has been with Certified Transmission since 1996 and been in the industry since 1987. He is an ASE master technician and has served as a master builder for the company in the past.