Over the last 28 years of being a technician, I have developed the habit of checking for and reading technical service bulletins at the forefront of the diagnostic process, especially when an unfamiliar vehicle exhibiting blatant or straightforward concerns comes into the shop. I have found many valuable nuggets of information while reading over these bulletins, from wiring concerns and connector issues, to transfer noises, water leaks, and engine and transmission performance concerns. The knowledge gained in reading through these bulletins has not only helped me with the vehicles I’m working on, but also increased my perspective and ability to connect the dots on other vehicles that don’t pertain to a current bulletin.

For instance, when I discovered bulletin number PIT5546G on a 2018 Chevy Silverado, it would have taken some extra time to connect the relationship of water being in the headlight causing a battery drain, along with the engine wanting to stay running intermittently with ignition off. The customer’s concerns matched the bulletin.

One concern addressed by bulletins yielding only moderate success is regarding transmission shudders. I’ve had a few make a difference with a “flash and flush”-style bulletin—but I emphasize the word “few.” For instance, the Honda Odyssey bulletin number 17-043 addresses judder from the torque converter. I’ve performed that TSB multiple times on vehicles exhibiting the issue to varying degrees, from severe to mild, with no change after following the bulletin. Every case required a transmission replacement in the end. Similarly, 6L80 or 8L90 shudder concern bulletins I’ve applied to vehicles have failed more often than not.

In a specific case, a 2019 Ford Edge with a 2.0L engine and equipped with an 8F35 transmission and the Auto Stop feature arrived at our shop exhibiting what the customer called a “jerk, or surge.” I was incredibly hesitant when I came across the TSB addressing this concern. Now, this TSB does not specifically speak of flushing—rather, it only speaks of reprogramming and reinstalling solenoid numbers.

Since that time, I’ve had ten or so of these vehicles come through in varying degrees of severity, and I now have quite a bit of confidence in the effectiveness of this bulletin. I will say, however, in each instance I did flush the fluid, which was dark and degraded.

The TSB I am referring to is bulletin number 21-2389 from November 2021. This bulletin states that some of the 2019 through 2021 Ford Edge or Lincoln Nautilus vehicles built on or before March 11, 2021, and equipped within 8F35 transmission, may exhibit a shutter/buck/jerk while driving up to 35 MPH, and that this may be due to software (calibration) in the powertrain control module.

All ten of the vehicles I have applied the bulletin to have the same powertrain specs as the subject vehicle. In every case, the customer complaint included the word “buck” or “jerk.” For the vehicles I worked on, the concern did exceed the TSB’s 35 MPH limitation, so I’m not sure why the bulletin mentions 35 MPH as being the cap speed. The vehicle mileage ranged from about 50,000 miles to 90,000 miles on these vehicles. The most severe case had 92,500 miles; this case is the one I will detail here as it was kind of an experiment for me. I was truly convinced that this TSB could not solve or save this one.

The vehicle was another 2019 Ford Edge. It had a severe jerk, almost binding any time on or off the throttle with the speed varying from takeoff, up to around 60 MPH. It also had a code P0741 (torque converter clutch solenoid circuit performance stuck off). This vehicle felt like someone was behind the car, bumping it in the rear pretty much all the way through the speed range. The more the throttle pressure increased, the more pronounced and severe the symptoms were.

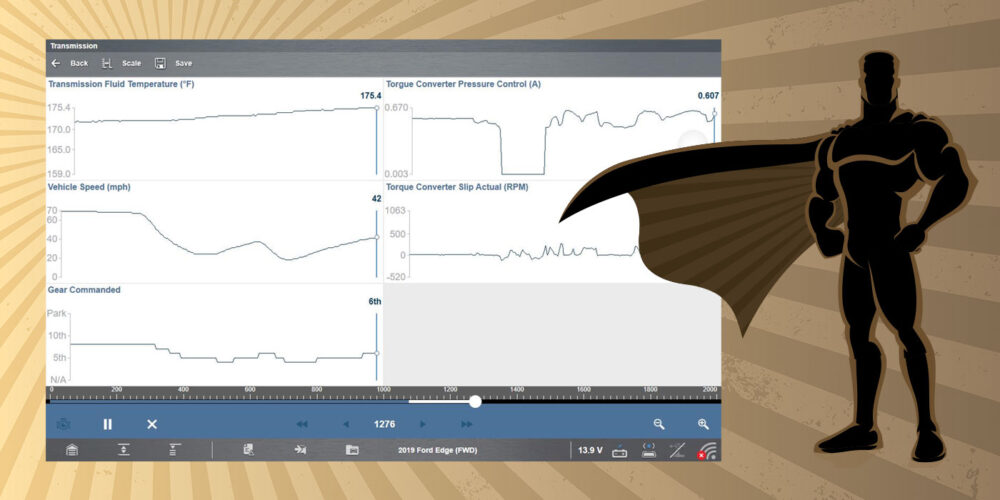

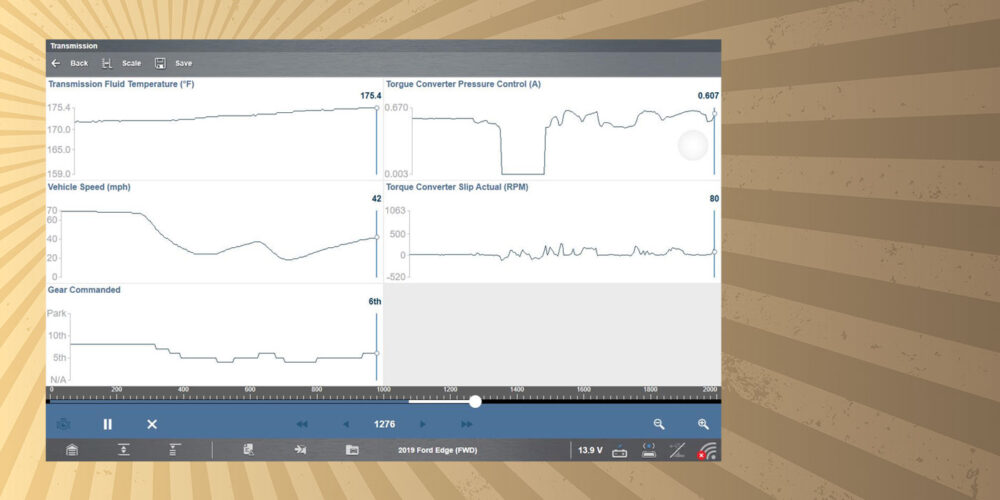

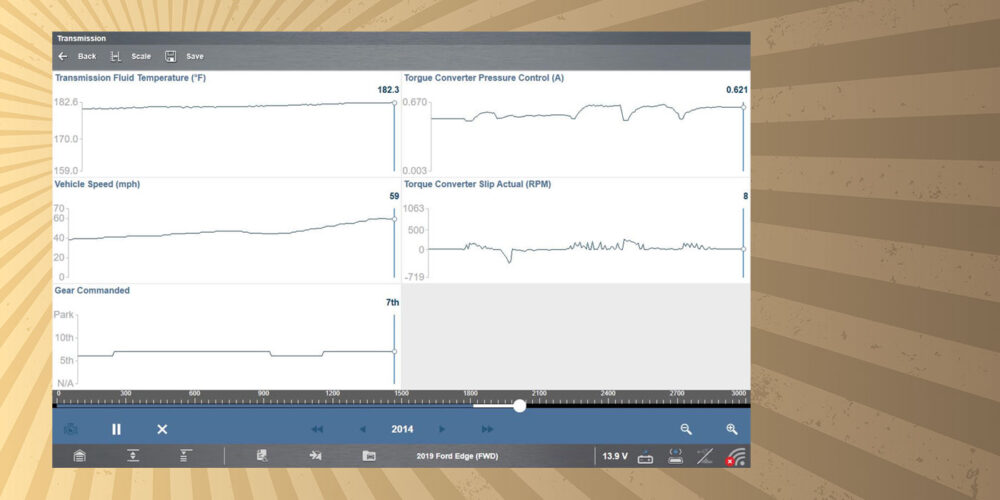

If you take a look at the images of TCC slip PID, you’ll see:

- Figure 1 was slowing down with light throttle pressure.

- Figure 2 was doing the opposite—speeding up with light throttle pressure.

- Figure 3 was from a complete stop up to 40 MPH.

Looking at these graphs, I’m sure at least some readers have a good idea of what it probably felt like; the plateau shape bumps really had a bind-like feel. The graph is only showing what I felt once the TCC was applied. I could feel it immediately from takeoff the moment the car started moving.

I brought it in to perform the TSB but exchanged the transmission fluid prior to the programming. Once the fluid was looking good, I went to my laptop and opened my FJDS software (our company uses the Snap-On passthrough Pro 4 as an interface, but I know there are many others that work very well). For all those that are performing programming on a regular basis, this is nothing new; the only slightly different question it asked before selecting the software was the following: “Has the crankcase pressure sensor been removed and replaced with a sensorless ventilation tube assembly?” The answer to this question on each of the vehicles I had worked on was no.

As I mentioned at the beginning, I thought there might be a very, very slim chance that the bulletin would correct this concern. So, to add to this experiment, I decided to not reinstall the solenoid numbers at that time like it states in the TSB. I had done this on all the other vehicles with almost instant improvement (though one or two of them did have to go through the gears at least once). This time I decided to just flush and reprogram the powertrain control module. I did not want to reinstall solenoid numbers at this time because I wanted to see what would happen. I wanted to verify that the software was indeed what was fixing this and that installing the solenoid numbers was just causing it to learn faster. I was also genuinely curious how much the fluid change was affecting it as well.

On the initial drive without installing solenoid numbers, I could tell that the software was helping. The problem was still there, but I could tell after ten miles of driving that it was trying to adjust and that it was getting much better. In fact, it got to the point where it was only noticeable during converter apply throttle movement. I went back to the shop and reinstalled solenoid numbers, which is a pretty straightforward process.

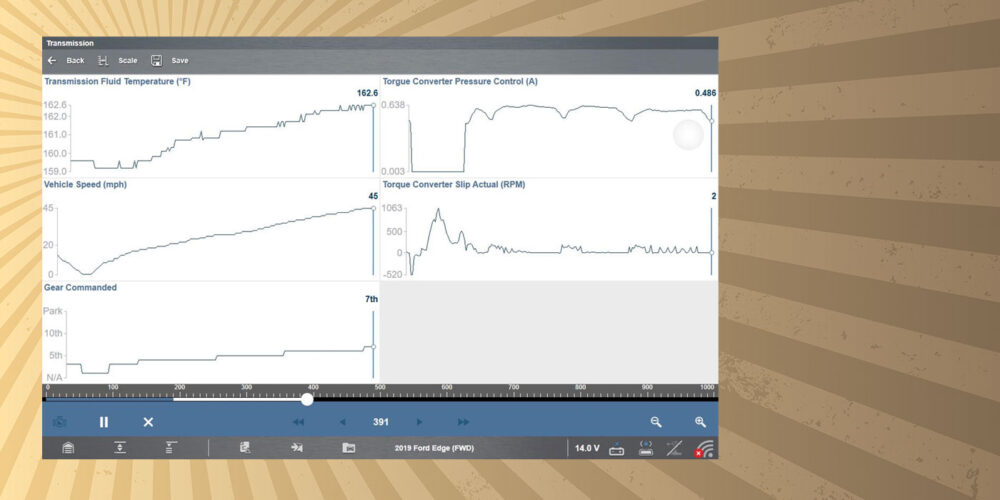

Don’t worry about trying to find the solenoid strategy and body numbers on the unit, as the tool will display the numbers that are already installed. All that is necessary is copying those down and reinstalling the exact same numbers. After doing that, everything was immediately gone. I did drive it for another thirty miles over the next two days just to make sure that P0741 didn’t sneak back in, but I had a lot of confidence in the repair because I did not see any slip the during the road test. Figure 4 is a screenshot after TSB was performed monitoring slip data.

As you can imagine, in almost all the cases I perform this TSB on, we were heroes to the customers. In three of the cases, they had been taken the vehicle to their local dealer and were told that they had unit failures and were unable to get a unit and install it for about six to 10 weeks. They brought it to us with the hopes of us being able to have a unit installed in a much faster timeframe, but instead we were able to resolve the problem with what amounts to a simple programming flash.

With the complexity of today’s modern vehicles and manufacturers constantly evolving, as technicians we are going to have to stay on top of our game. To accomplish this, we must constantly increase our understanding of systems and theories of operation. This includes spending time with other technicians in seminars and ongoing technical training classes. Reading over technical service bulletins and descriptions of operation on unfamiliar systems is necessary, as well. These practices will help us be heroes for our customers. Developing a habit of diligently reading through technical service bulletins and increasing our capacity of understanding and knowledge is key in developing a habit of chasing efficiency, and improving customer satisfaction.

Read more stories in our R&R Tech series here.

Kevin Wayne is a diagnostician at the Liberty, MO Certified Transmission location. He has been with the company since 2014. Kevin has been in the automotive field for more than 25 years, specializing in engine, transmission and electrical diagnostics. He is an ASE Certified Master Technician with L1 advanced level diagnostics certification.