The complaint

A 2015 Ford F-250 equipped with the 6R140W transmission has just been overhauled. Shortly afterward, the transmission has begun to develop forward and reverse engagement problems when the unit is cold. As it warms up towards operating temperature, the engagement problems diminish and do not return until the next cooldown period. Trouble codes P0722 “Output Shaft Speed Sensor No Signal” and U0422 “Invalid Data Received From Body Control Module” are set.

The cause

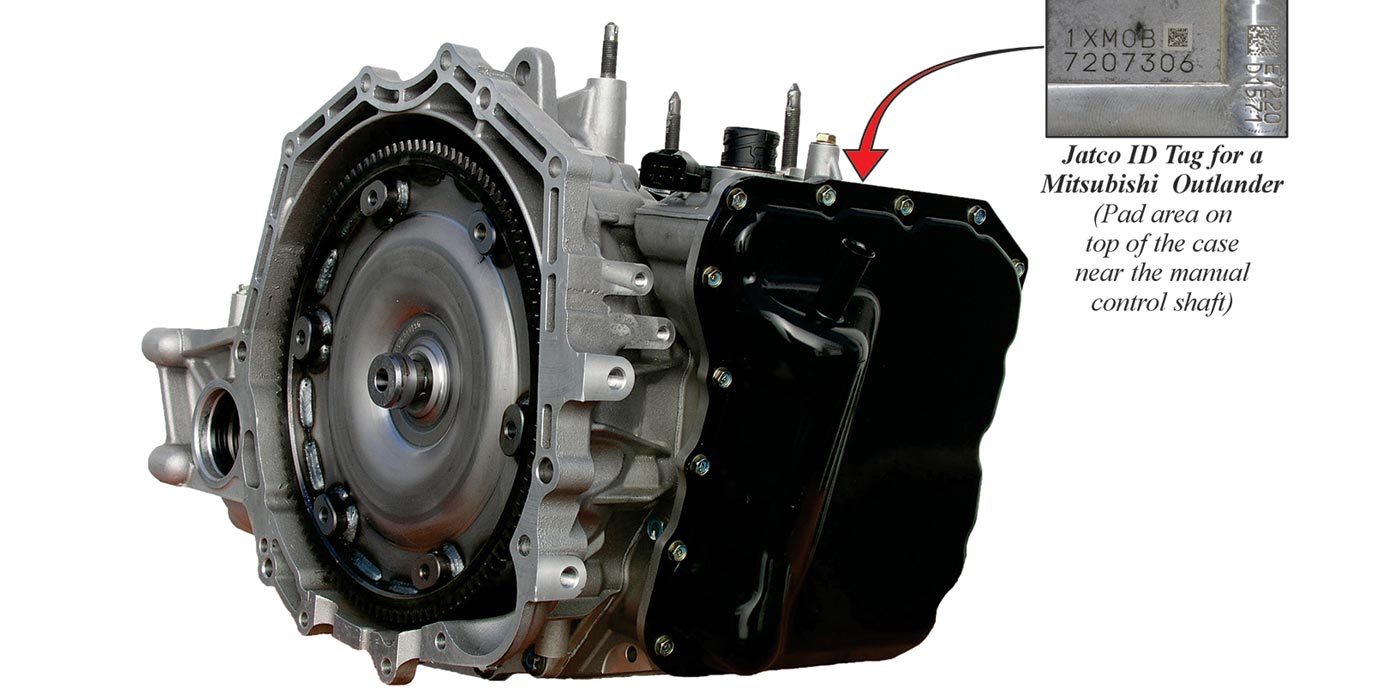

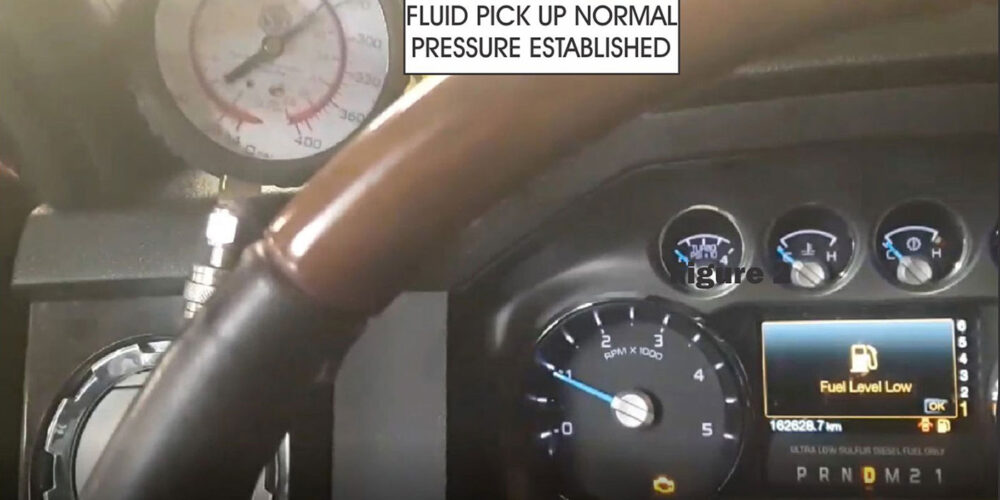

An undersized o-ring seal on the new filter neck (refer to Figure 1 above), is causing pump cavitation. The pressure gauge connected to the line pressure port indicates zero pressure (see Figure 2), which would explain the no engagement complaint.

Even with the case connector disconnected, the gauge still indicated zero pressure. As the transmission warms up the o-ring seal swells enough to allow fluid to be picked up, at which point the pressure gauge jumps up to the correct line pressure as seen in Figure 3.

Note: This may have been mistaken for a drain back problem, but the dipstick did not indicate an over-full condition when the transmission was cold.

The correction

Replacement of the filter with a good o-ring seal eliminated the engagement problem entirely. The above listed trouble codes were cleared and did not return, as those code definitions were falsely generated.

Read more articles in our Transmission Tech/Talk series here.