Body of Evidence

- Subject: Adjustment of clutch-control valves

- Units: TF60 (09G), TF80, TF81 (AF21)

- Vehicle Applications: VW, Mini Cooper, Volvo, GM, Ford, Mazda

- Essential Reading: Rebuilder, Diagnostician

- Author: Jeff Parlee

Have you ever installed a TF80, TF81 or TF60 after overhaul and it has had harsh shifts or engagements, or maybe there has been a flare/bump upshift or harsh coast-down clunks? Most times, clearing the shift adapts and driving the vehicle to relearn the shifts will correct these annoying problems. After a good, long test drive to relearn the shift adapts, sometimes a shifting or engagement problem remains. Assuming that there is not excessive wear in the valve body and the linear solenoids are good, the clutch-control valves on the valve body can be adjusted to correct these problems.

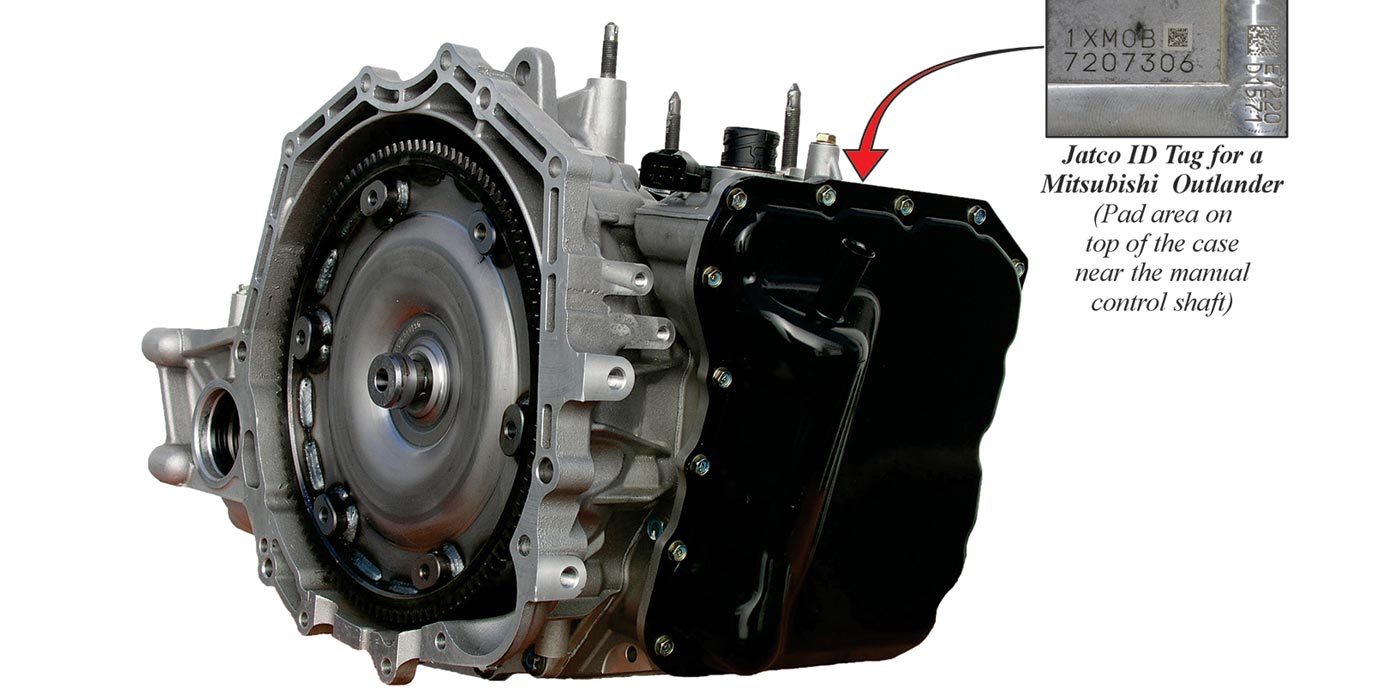

First, let’s get a little background on these valve bodies and clutch-control valves. The TF60, also known as 09G, is used in Volkswagens and Mini Coopers; the TF80 is used in Volvo and GM vehicles in the United States; and the TF81 (also known as AF21), is used in Ford and Mazda vehicles in the United States.

The TF60, TF80 and TF81 transmissions have the same solenoid firing order and the same clutch and band application, and all three use clutch-control valves and linear solenoids to control the shifts and engagements. All three of these transmissions are adaptive-learn and require that the shift adapts be cleared and then the vehicle driven to relearn the shift adapts. Ford, Mazda and Volvo seem to relearn the shift adapts quickly, but Volkswagen seems to take the longest to relearn.

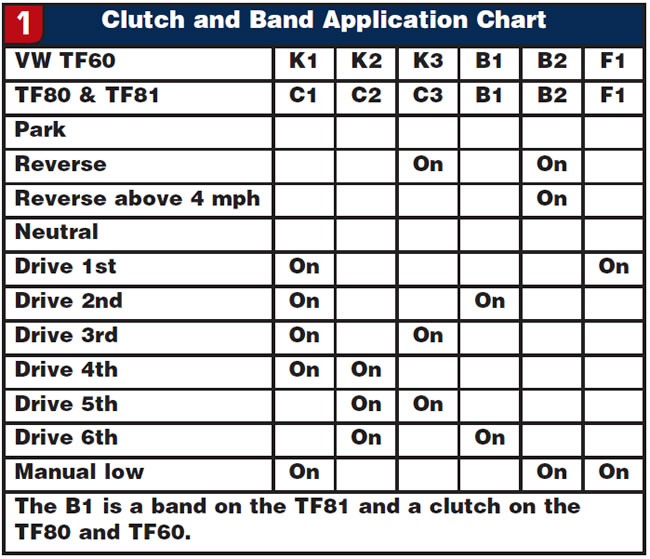

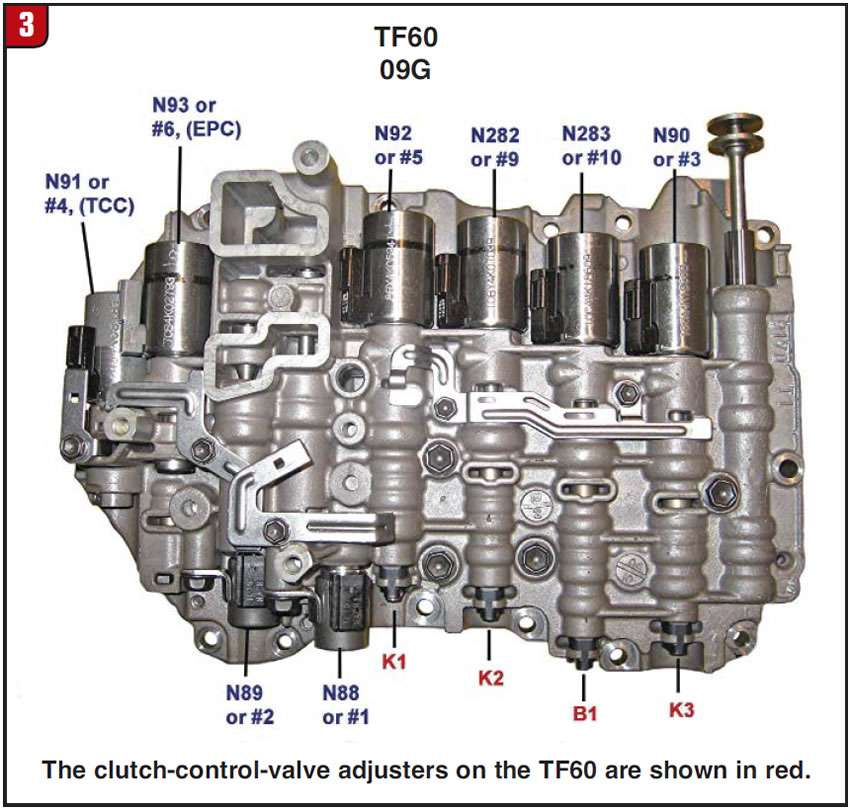

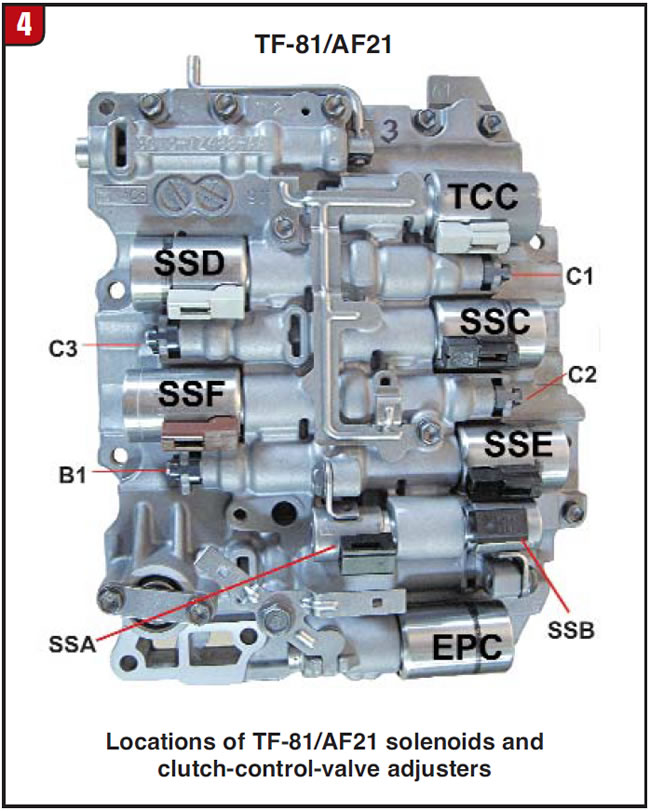

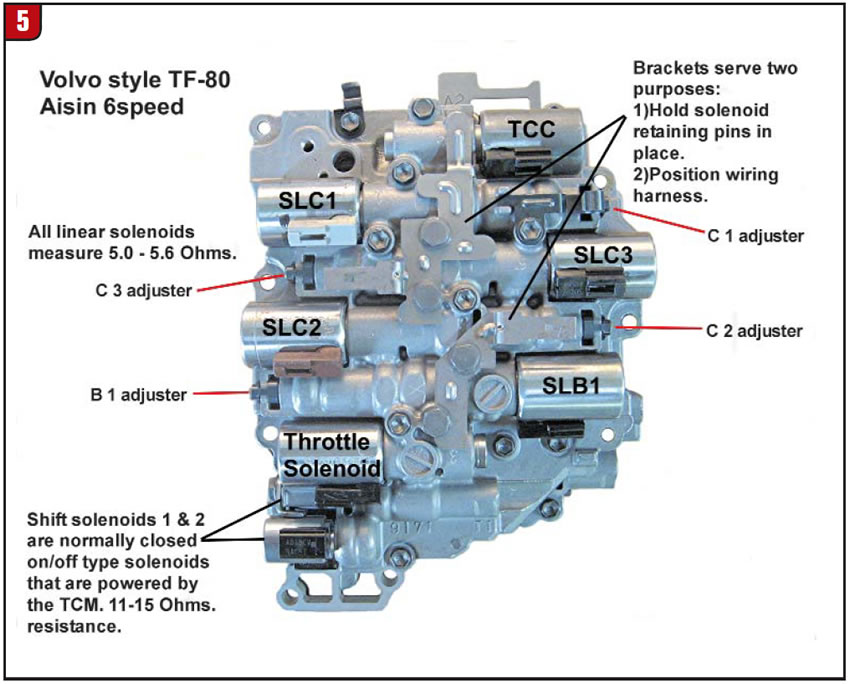

As you can see in Figure 1, the four clutches (K1, K2, K3 and B1) control at least one of the shifts or engagements. Clutch-control valves regulate the engagement of these four clutches. For example, the K3 controls the reverse engagement, the 2-3 shift and the 4-5 shift.

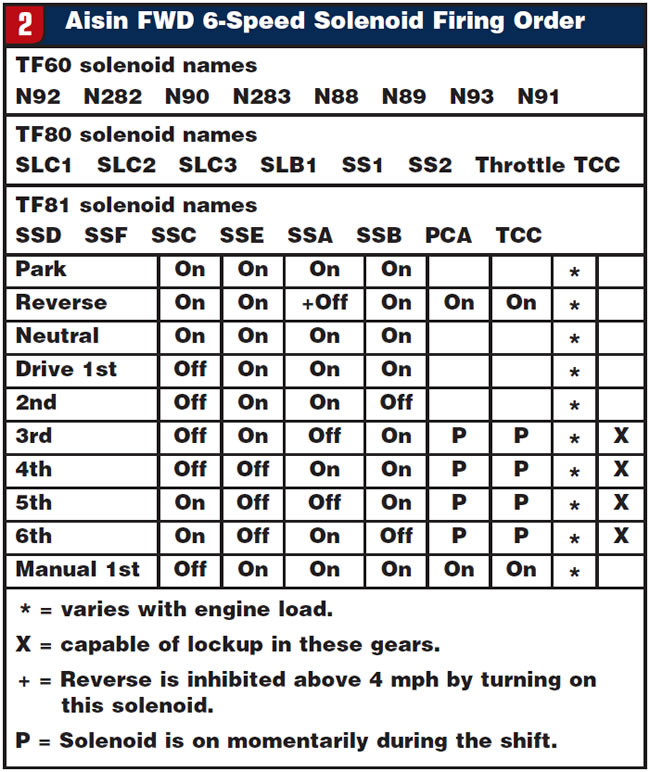

The linear solenoids that control the clutch-control valves are pulsed off to apply the clutch (Figure 2). When the solenoid is electrically off, it is flowing maximum oil to the clutch-control valve.

A clutch-control-valve lineup consists of a linear solenoid, clutch-control valve, spring and adjuster.

How it works: The solenoid sends oil to the end of the clutch-control valve, compressing the spring against the adjuster. As the solenoid pulses off, the clutch-control valve moves down the bore, regulating line pressure to the clutch and accumulator. If, during the solenoid pulsing, the valve does not move far enough down the bore, the result will be not enough pressure to the clutch and a flared shift. If the flare is long enough, the TCM will raise line pressure to get the clutch applied and the result will be a flare/bump shift. Conversely, if the clutch-control valve moves too far down the bore during solenoid pulsing, the result will be too much pressure and a harsh shift. You can see the importance of the proper spring tension on the clutch-control valve. If you have a delayed engagement or flared shift you would want to turn the adjuster counterclockwise to decrease spring tension and allow the valve to move a little farther, providing more pressure to the clutch.

For example, say that you have a delay into reverse and a 2-3 flare. You would turn the K3 or C3 adjuster counterclockwise.

There are several reasons why you may need to adjust a clutch-control valve:

- Clutch-pack clearance may be different from OEM; always check the thickness of replacement steels and frictions.

- Bonded pistons may be worn, allowing clutch pressure to leak.

- Sealing rings may not be sealing correctly.

- Slight wear in the valve body.

The most-common shift/engagement complaints are:

- Delay/bump into reverse, 2-3 flare/bump and 4-5 flare

- 3-4 flare/bump or 3-4 neutral

- Harsh 1-2 and 5-6 (sometimes 5-6 feels fine).

The adjustment depends on how severe the problem is.

- A delay into reverse with a small flare on the 2-3: K3/C3, turn adjuster counterclockwise 3/4 turn.

- A delay/bump into reverse, 2-3 flare bump & 4-5 flare: K3/C3, turn adjuster counterclockwise 11/2 turns.

- A 3-4 slight flare: K2/C2, counterclockwise 1 turn.

- A 3-4 flare/bump: K2/C2, counterclockwise 11/4-11/2 turns.

- A 3-4 neutral: K2/C2, counterclockwise 2-21/4 turns.

- A firm 1-2 with no flare: B1, clockwise 3/4-1 turn.

See figures 3, 4 and 5 for adjuster locations.

Remember; always try to relearn the TCM first. Follow all the rules: no codes, transmission at operating temperature, drive vehicle at 20%-25% throttle angle through all the gears and then allow 20-40 seconds to slowly come to a stop so that the TCM can relearn the coasting downshifts. The relearn can take as little as 15 minutes on a Ford, about 30 minutes on a Volkswagen. Remember that Volkswagen takes longer to relearn and the shifts may deteriorate before the relearn is complete. Only after a relearn should you try any adjustments. Short-cutting the relearn to perform adjustments right away can cause you to have to pull the pan again to make still more adjustments.

Jeff Parlee is the director of product support at Valve Body Xpress.