Shift of the shaft: Diagnosing Chrysler 48RE manual shaft issues

The TorqueFlite transmission has been around since mid-to-late 1950s. There have been many changes surrounding the manual shaft and rooster comb through the years. This transmission shaft controls the position of the manual valve that directs oil for the gear ranges, but it also is used for a Reverse light control as well as Park/Neutral

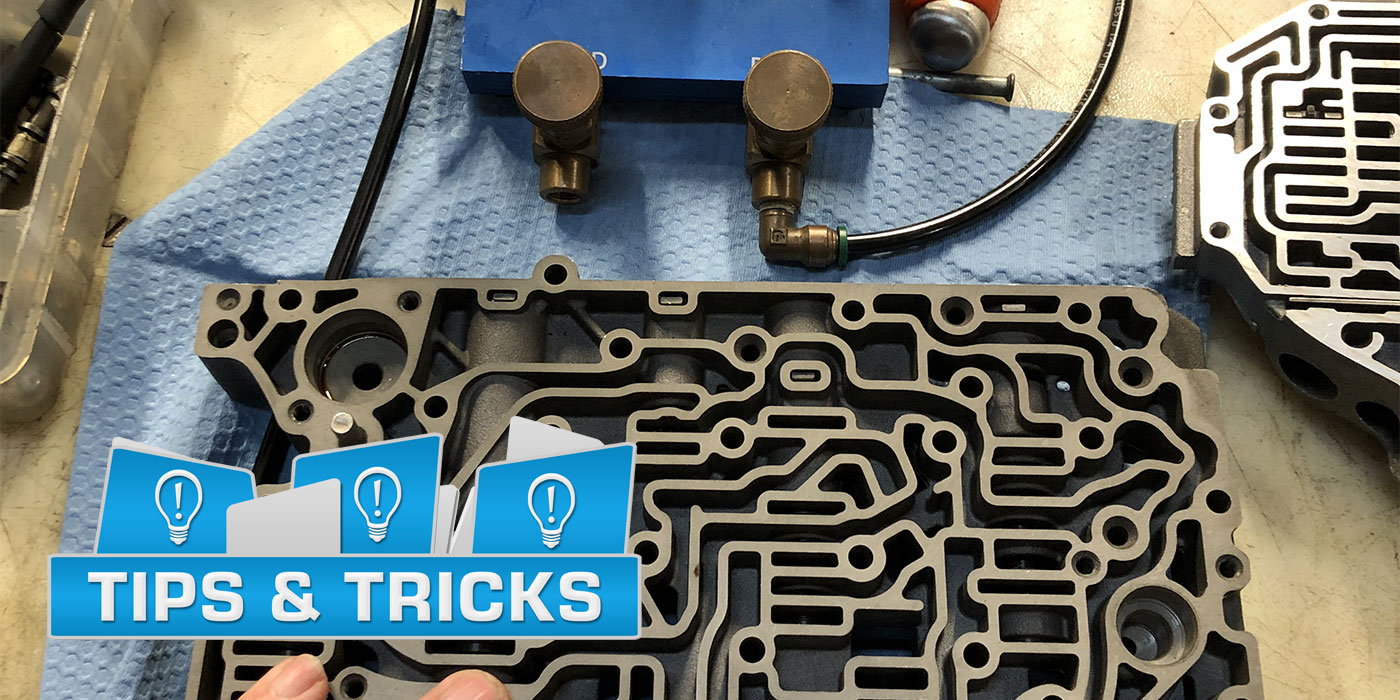

Tips and tricks for Chrysler switch valve plug testing

As technicians, we are often faced with build issues that can sometimes be frustrating at first. But with a little ingenuity, these frustrations can be turned around and made simple. In 1989, Dodge came out with the first fully hydraulic electronic-solenoid shifting transmission, the A604 (no shift valves), which later became the 41TE. Originally, there

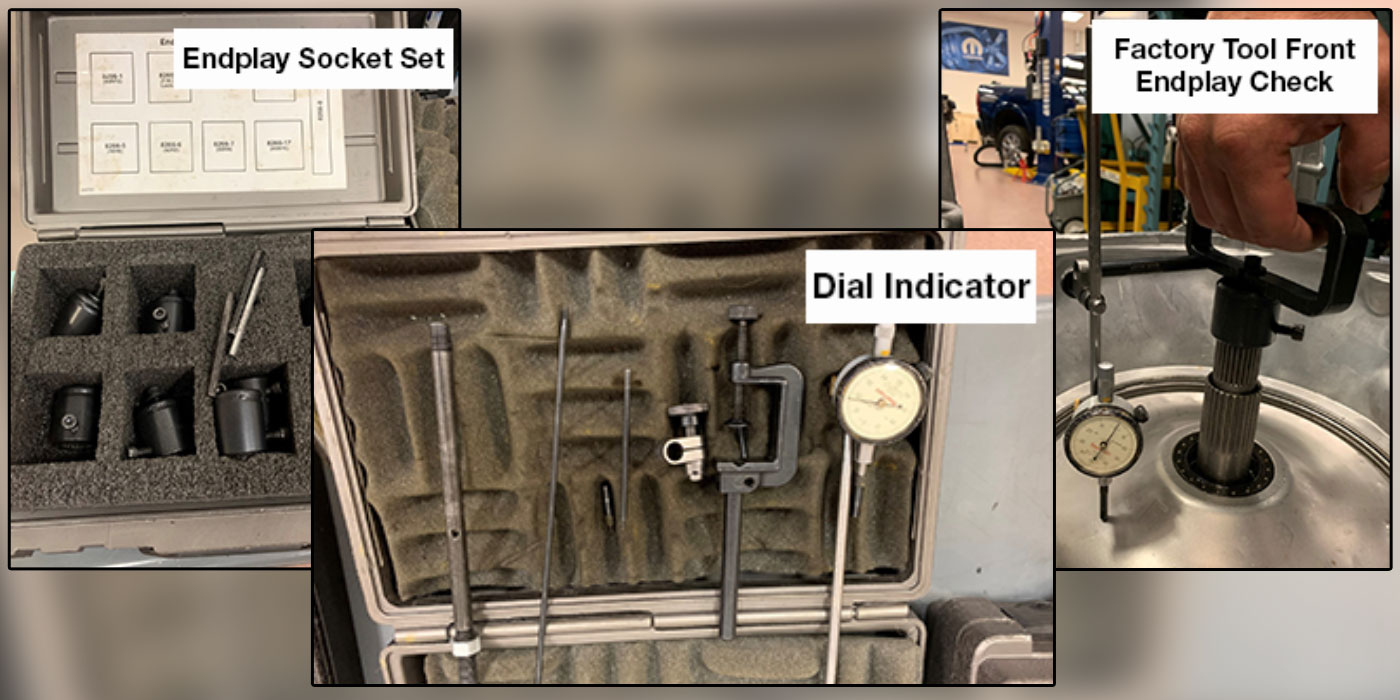

How to easily check endplays in Chrysler RFE transmissions

When building a reliable transmission for everyday drivers, it’s tempting to skip checking gear set endplay because of the factory tool cost. Often, I hear: “I feel movement, so at least I know it is not going to bind up;” or “This play feels good to the touch, so it is okay;” or “It’s not

Transmission Testing & Repairs: Make Sure You’re Vacuum Testing

Vacuum testing has become a trusted method for identifying valve body problems and verifying repairs.

Seal the Deal: Preventing Comebacks with Non-Valve-Body Vacuum Testing

Vacuum testing is not a new process in the automotive field. After engine builders “lapped” a sealable mating surface between valves and their seats, they would use vacuum to test for any leaks that needed to be addressed. Vacuum testing is relatively new to the transmission rebuilding industry, though.

Playing with Transmissions

Tech-support hotlines have been burning up for years with phone calls concerning rapid gear-train failure in GM TH400 transmissions after routine rebuild or repair. It’s time to address the issues that cause this and reverse widespread confusion surrounding gear-train setup on this and similar units. Today we will clear up the mystery in setting proper endplay for this transmission. If tolerances are not set correctly, costly comebacks can result.

Understanding these basic checks on the 400 will give you back-ground knowledge in setting build procedures that will be used with similar gear sets, such as 4L80-E.

Diagnosing the Elusive No Reverse with the 4L80-E

Diagnosing a shift concern can be easy, as long as you understand some basic techniques to help get to the root of the problem. A reliable and orderly diagnostic approach is splitting the circuits. Splitting the circuits means separating and analyzing the hydraulic, electrical and mechanical issues that could create the problem. Let’s follow through the flow of diagnosis in this one together. Make sure you have the following on hand: a line-pressure-test spec sheet with test-port locations, and a clutch and band chart to help eliminate other areas that may be associated with the problem shift.