Technically Speaking

Author: Mike Riley, Technical Editor

Subject Matter: Automatic transmission

Unit: 5R110W

Vehicle Application: Ford trucks

Issue: Upgrades

Still no end in sight

Beginning with the launch of the 5R110W in 2003, the number of tweaks has been unending. Some of the item upgrades had been limited to the item itself, whereas others resulted in rather expensive and heavy packages.

These OEM modifications have rendered cost containment nonexistent. It’s hard to limit the overall repair cost when the part components of the repair enter the stratosphere.

Certain upgrades like the pump and valve body were not much of an issue, unlike what happened regarding the coast-clutch assembly. Initially, there was a problem with the overdrive one-way clutch (OWC), which is a mechanical diode. The fix was to increase the width of the OWC by about 0.040 inch. This change triggered the first OD-package launch, due to the wider OWC and repositioning of the snap-ring groove in the coast-clutch drum. The package included the OWC, coast-clutch drum and OD sun gear. Gas or diesel applications didn’t matter.

The pace really picked up at the front end, in 2007, when Ford released four new packages, which depended upon whether the engine was gas or diesel and whether the transmission had PTO. This change made the previous one look like child’s play.

To start with, the OD OWC was split into two versions, one gas and one diesel. The gas version has two missing teeth, whereas the diesel has a full set. Functionally, there is not much difference.

Although the coast-clutch drum is stamped “gas” or “diesel,” they are the same. The stamping denotes only which OWC is included. The drum, in addition, is fully loaded.

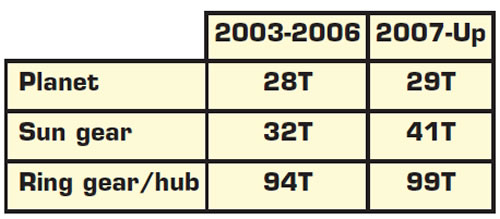

What makes this worse is that beyond the OWC and coast drum is the planetary gear set. It’s all different. The planet, sun-gear and ring tooth counts were changed as follows:

This change in tooth count resulted in a slight ratio difference. Last, non-PTO applications have just a sensor ring bolted to the planet, whereas PTO applications have a drive gear as well. All four packages cost several hundred dollars. All previous-model components have been deleted. The four packages are:

So much for the front end of the transmission; what about the back end, behind the center support?

In 2005, the gloves came off and a lot of stuff got changed, similar to the OD section thing in 2007. To start with, the front planetary components changed tooth counts and diameters (Figure 1). Along with the appearance difference between the ’03-04 on the left and the ’05-up on the right is the forward-clutch spline count. The forward frictions were changed from 90 teeth to 76 teeth. The forward drum changed slightly as well. Planet-gear tooth count increased from 18 in 03-04 to 23 for 2005-up. The tooth count for the front ring gear and hub went from 78 to 101 in ’05. Along with the thrust washer increasing in diameter is the lube-dam change. The lube dam increased in diameter, and there are now two types. Gas applications have six tabs and diesels have four tabs.

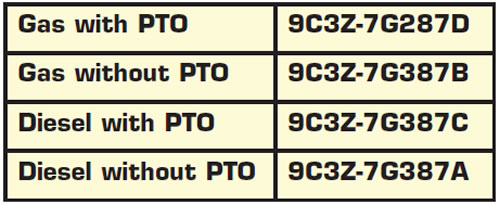

Not only did the tooth count of the front sun gear change, but so did the shell (Figure 2). Although the overall length of the shell is different, the main area of concern is the back side of the shell. Using the first-design rear planet with the ’05-up shell can cause interference. The sun-gear tooth count went from 42 to 55 in 2005.

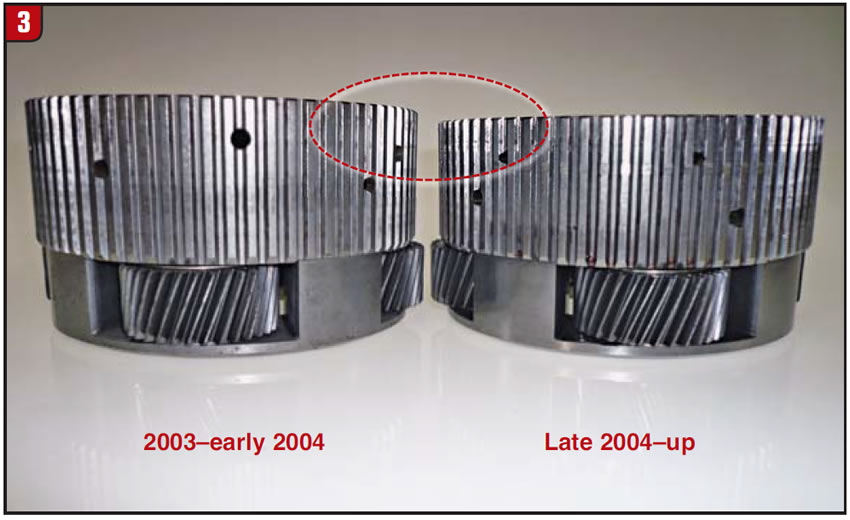

A new rear planet was also included in the ’05-up package as a precaution, due to earlier failures. By 2004 the rear planet was updated to limit the pinion-gear pins from walking out. The clutch spline length was shortened as well (Figure 3). The ’03 version on the left should not be used at all. Other items like thrust bearings and bolts were included in the 2005 package (5C3Z-7A398SA), which is now no longer available (NLA).

The most-recent big hurt circles around the low OWC, which also doubles as the low/reverse-clutch backing plate. In late 2008 Ford started to attach the OWC to the rear planet (Figure 4) for a couple of reasons. By permanently attaching the two components, both planet thrust washers were omitted, saving cost and labor. In addition, the low/reverse clutch plates are now part of the assembly, also saving labor cost. This modification may have been great for the factory but is wreaking havoc for service and repair. To just replace the OWC, let alone the low/reverse clutches, requires expensive iron. Again, all previous-design components are NLA.

One item of importance that was upgraded, without impacting a lot of other stuff, was the low/reverse-clutch retaining ring (Figure 5). The snap ring tended to pop out, which meant bad news. The new ring is designed to avoid that problem. As you can see in Figure 5, the ends are rolled outward on the new design.

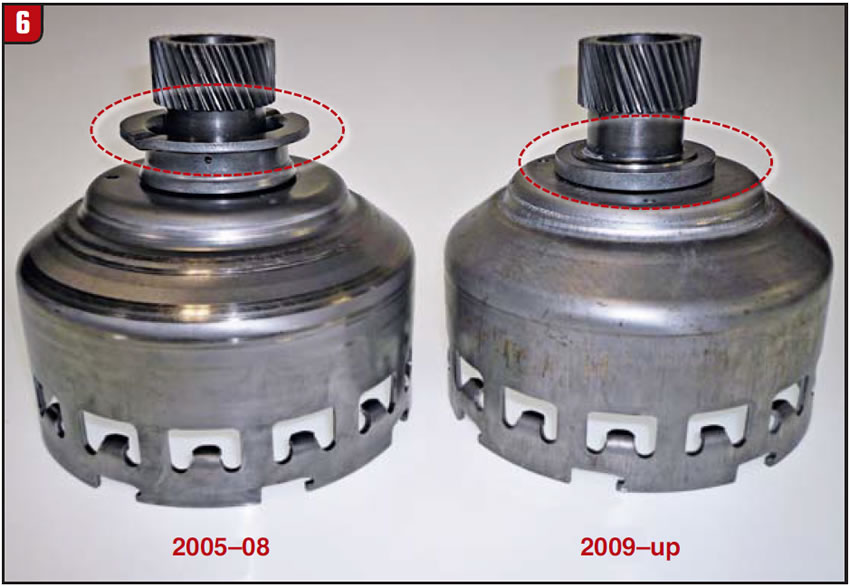

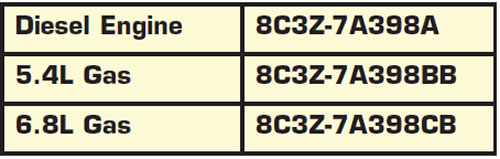

When the new-design rear planet without washers went into production, another item was tweaked as well, the sun gear and shell (Figure 6). Since there are no planet washers, there is no need for a planet-washer surface, which is why the shell collar was omitted on the shell on the right. The sun gear and other shell dimensions are unchanged.

Currently, there are three big packages that will retrofit to 2003, although the price tag is way north of a grand. The packages contain half of the transmission, so to speak, and apply as follows:

The basic difference between diesel and gas is the front planet and lube dam, whereas the 5.4L gas uses a five-pack low/reverse clutch and the 6.8L gas and diesel use a six-pack setup.

The question remains, what is necessary for repair? Can the unit be repaired when the OWC or rear planet is bad, with OE new parts, without the costly packages? The rear-planet/OWC assembly is available separately and for much less cost. The two part numbers are 9C3Z-7D006B for the five-clutch pack and 9C3Z-7D006AB for the six-clutch pack.

The first thing to determine is, will a planet without thrust washers work in a unit that originally had them? It’s all about clearances and stack-up.

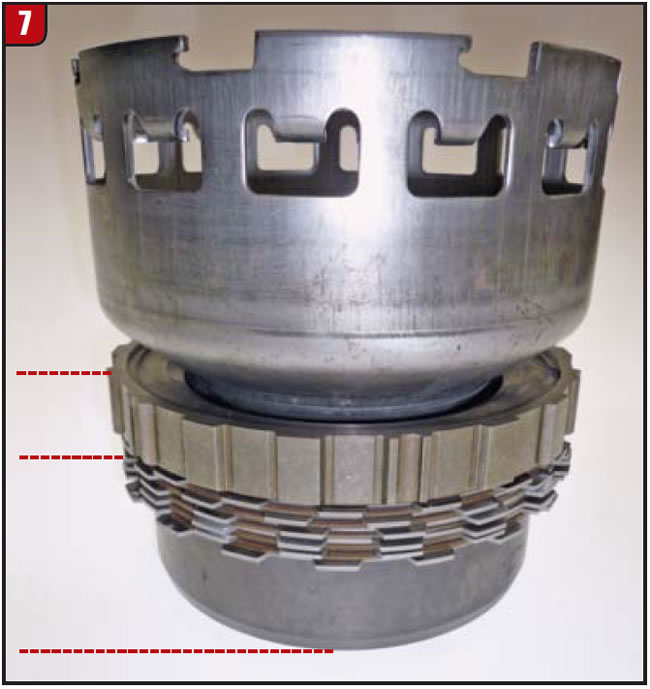

The planet thrust washers had nothing to do with overall endplay. Now, with the planet firmly attached to the OWC, it can no longer “float” back and forth (Figure 7). The stack-up starts at the back of the case to the rear ring and thrust bearing, forward through the sun gear and thrust bearings to the front planet, clutch drums and washers, ending at the center support. How the OWC is positioned in this case is the key.

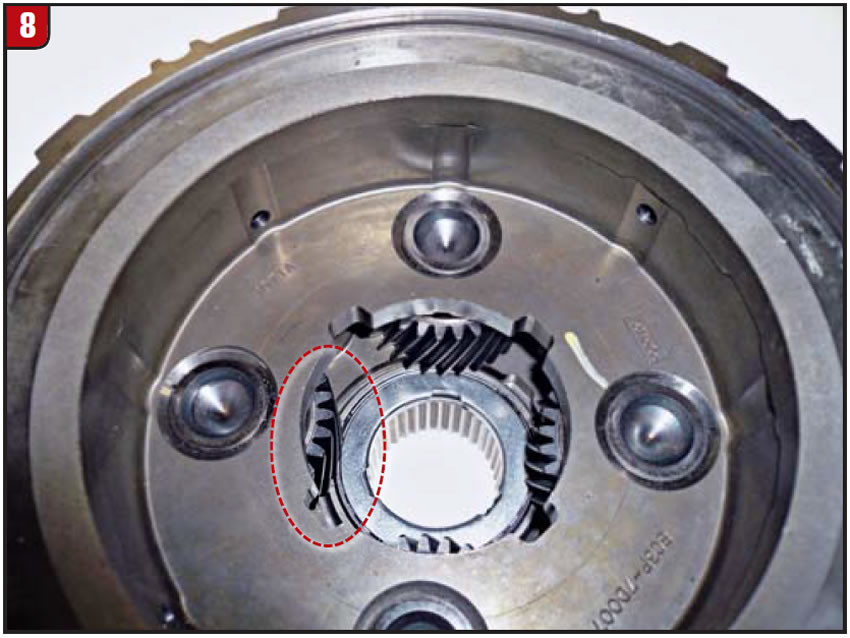

To see whether this will work out, start by dropping the rear ring gear and thrust bearing into the case. Then set the OWC/planet assembly into position and install the retaining ring. Using snap-ring pliers, move the ring gear up and down and check total travel (Figure 8). It should be well over 1/16 inch. Then using a depth mic, measure from the top of the front thrust bearing to what was the washer surface of the planet. Finally, measure the sun gear and shell from the end of the sun gear to the washer surface of the shell. Compare the two measurements to see whether sufficient clearance exists between the sun-gear shell and rear-planet surface. If it’s too close, whack away some of the shell collar.

The OWC lug position (where the OWC sits) seems to be consistent on early and late cases (Figure 9), which is why the stack-up test should work.

With proper checks and balances, a 5R110W can be repaired without resorting to major upgrade packages and needless expense.