R&R Tech

- Author: Barry Bartlett

- Subject Matter: Diagnosis

- Issue: Premature shift to overdrive

It seems that we have run into several different vehicles in the recent past that have had stacked shifts, and shifted into overdrive by 20 mph. While the symptoms were the same, the diagnoses and repairs were very different. Here is what we found to be the problem on each one.

The first vehicle was a 1999 GMC dump truck that another shop had been working on for some time but were still unable to determine the cause of the problem. They had replaced the PCM with a new unit, checked all the sensors and verified that the speedometer and the computer were displaying the correct speed.

I checked the signals from the speed buffer and all showed a good signal on the lab scope, but as I followed wiring diagrams, I discovered that there were two signal wires from the speed buffer to the computer. A check of the connector view and a trace of the wiring revealed an open circuit in the harness of one of the reference signals, labeled “A/T ISS Sensor”. Since the PCM needs this signal to time the shifts properly, the open circuit was the cause of the early shifts. A quick repair of the wiring solved this issue.

The next truck was a 1994 C1500 Chevy pickup that came in with a burned up transmission. After the installation of a remanufactured unit, we discovered that this vehicle also had stacked shifts and was shifting into fourth gear by 20 mph as well. Due to the inoperative original unit, we did not have an opportunity to drive the truck until we installed the new transmission. It is quite possible that the original unit failed due to the issues were we experiencing after the installation.

The first place I went was to the speed buffer. After testing the signals and checking that the wiring was good, I noted that this vehicle only had a single wire to the computer, unlike the previous case. Testing showed the correct reading on the speedo and the scan tool. As I followed the connector pin by pin, I discovered that it had a wire that was supposed to go to the transfer case module (terminal F8, dark blue wire), but this was a two-wheel-drive truck not a four-wheel-drive, so it did not have a transfer case module. I was not sure what the signal wire was shorted to, so I cut the wire at the computer and lo and behold, it began to shift normally. Somehow it was getting information from somewhere (possibly a short or ground to another circuit), but the computer thought that the non-existent transfer case was in four-wheel low and was shifting accordingly, even though the speedometer read the correct speed.

The next one I ran into was a 1995 four-wheel-drive S10 Blazer. Like the first truck, it came from another shop that had spent several days trying to figure out the cause of the stacked shifts and shifting into fourth gear by 20 mph. I suspected that the problem was the signal from the Transfer Case Module, but I could not find any data or information on what the signal should be to the PCM. A simple disconnect of the Transfer Case Module brought back normal shifts. The replacement of the Transfer Case Module solved the problem on this one.

Our final example was an early 90s Toyota Corolla which came into the shop with no movement and burnt fluid so the transmission was pulled for remanufacturing. After installation, I discovered that we had another vehicle with stacked shifts, and a fourth-gear shift by 20 mph.

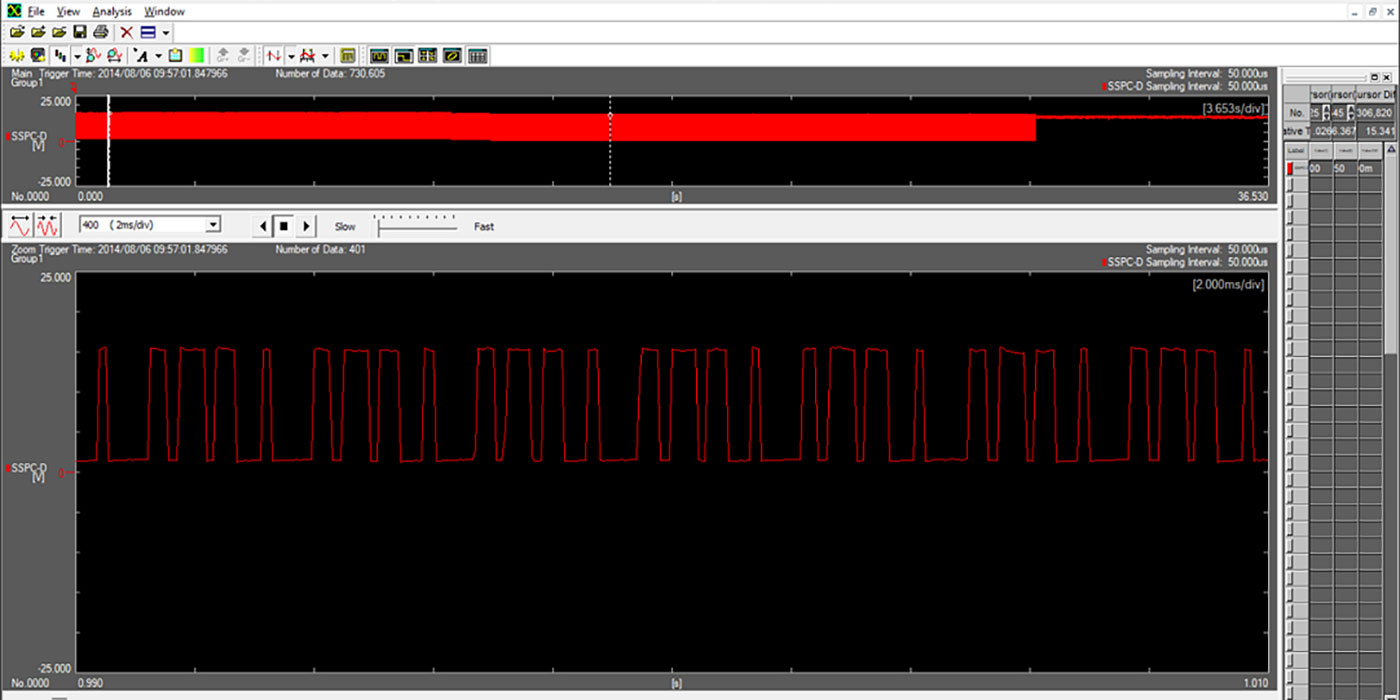

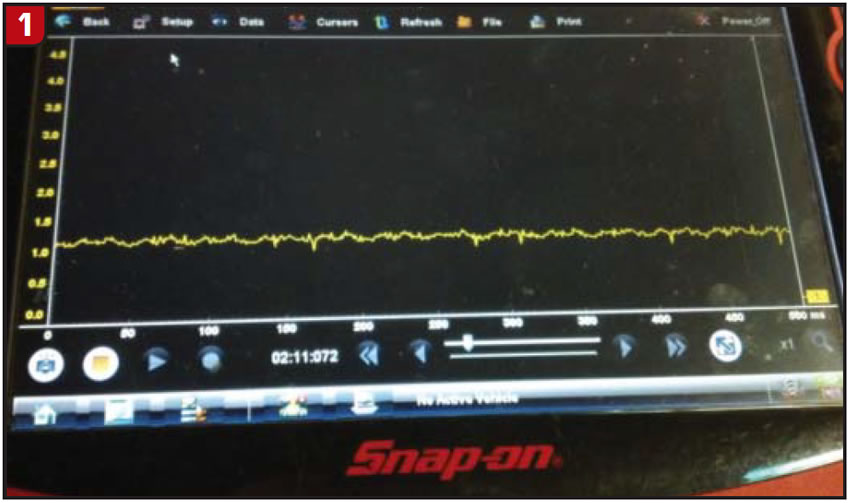

It was time to get out the lab scope and check the Output Speed Sensor, which revealed that there was a great deal of static coming from the sensor. We were unable to obtain another speed sensor, so I tried a remedy that I have used for years on Dodge trucks that experienced torque converter cycling on and off after lockup. This procedure uses a signal rectifier to filter out the noise on the signal wire from the Throttle Position Sensor to the computer to eliminate the static and produce a clean signal.

Here is the information from ATRA on how to make this signal rectifier, along with part numbers from Radio Shack. Pick up a resistor (part #271-1328, 3300 ohm) and a capacitor (#272-1436, 10uF). Put the 3300 ohm resistor inline on the signal wire you wish to clean up, and put the 10uF capacitor between the resistor and the computer. Attach the longer lead on the capacitor to the signal wire and attach the shorter lead to ground. The accompanying photos show the signal at the computer before and after the signal rectifier. Figure 1 shows a signal with static and Figure 2 shows the same signal with no static after the signal rectifier is put in place.

After installing the signal rectifier on the Toyota, the shifts were normal and the customer was satisfied.

Although the symptoms in all of these cases were the same, the repairs were slightly different but with one commonality to them: the cause of the problem in each case centered on some form of speed-sensor signal issue. Unless the diagnostics lead you to a component problem, a little trial-and-error may be required to get to the root cause of the problem. The books won’t always lead you to a solution. One thing to remember is that if all of the shifts are present (albeit stacked and erratic), the cause is likely electrical. With a little patience and time, the cause will reveal itself.

Barry Bartlett, a diagnostician at Certified Transmission, has over 45 years of automotive experience. He has done everything from managing, owning, and operating his own general repair facility to working in the transmission industry. He’s an ASE Master tech. with L1 advanced level diagnostics, the highest level of certification available. Barry and his wife Janet have been married 42 years and are proud parents of 6 children and 26 grandchildren.