Body of Evidence

- Subject: No 3-4 shift

- Unit: 4R100

- Vehicle Application: Ford truck

- Essential Reading: Rebuilder, Diagnostician

- Author: Joe Cangelosi

A friend of mine who owns a local transmission shop called me recently to see whether I could help with a difficult problem he was having with a transmission. He had taken in a Ford truck with a 4R100 transmission that had no fourth gear. The fluid was badly burnt and there was a lot of clutch material in the pan.

The transmission was pulled and disassembled. Sure enough, the snap ring that holds the overdrive-clutch-piston return spring had come out of the groove and the overdrive clutches were destroyed.

The job seemed pretty straightforward up to this point. A soft-parts overhaul was done along with overdrive steels, rebuilt torque converter and a new solenoid block. The transmission was reinstalled, filled with clean fluid and road tested. That’s when the job stopped being routine. The transmission still did not have fourth gear and after a short test drive set code P0734 for a gear-ratio error in fourth.

Now, as they say, is when the fun began. The first thing the shop did was to drop the valve body and separator plate. The overdrive-clutch feed bolt was checked for tightness and the clutches air tested. All seemed OK. Next, the valve body and accumulator body were disassembled and checked for sticking valves. Again, no problem was found. At this point it was decided to reassemble the transmission with the original solenoid block to see what would happen.

Unfortunately, the road test yielded the same results: no fourth gear and code P0734. Just to be on the safe side, this time the computer signal for fourth gear and the various computer input signals were checked. Again, all seemed OK, with the computer commanding the 3-4 shift right on time. There was not much left to do in the chassis, so it was decided to pull the unit and recheck the overdrive-clutch assembly.

When I got to the shop, the transmission was on the bench and apart. The builder and I looked over the overdrive-clutch support, piston seals and overdrive-clutch stack-up. We also rechecked the valve body and accumulator body for sticking valves. We both came up with nothing.

About this time we decided to try an air-pressure test of the clutch circuits with the unit assembled. In many instances this is a good test for leaks in the circuits of clutches that would be applied in forward or reverse with all the shift solenoids off. When a 4R100 is in fourth gear all the solenoids are off, so this test is a natural.

If you’re not familiar with this air test what you must do is completely assemble the transmission except for the pan and filter. With the unit assembled place the manual selector in drive or reverse (depending on which circuit you are checking), block the filter inlet and blow air into the line-pressure port, then listen for the clutch packs to apply or for escaping air. On some units you may have air escaping from the torque-converter-charge circuits in the front pump area. If this happens install the torque converter and bolt a box wrench across the bellhousing to be sure the converter does not push out.

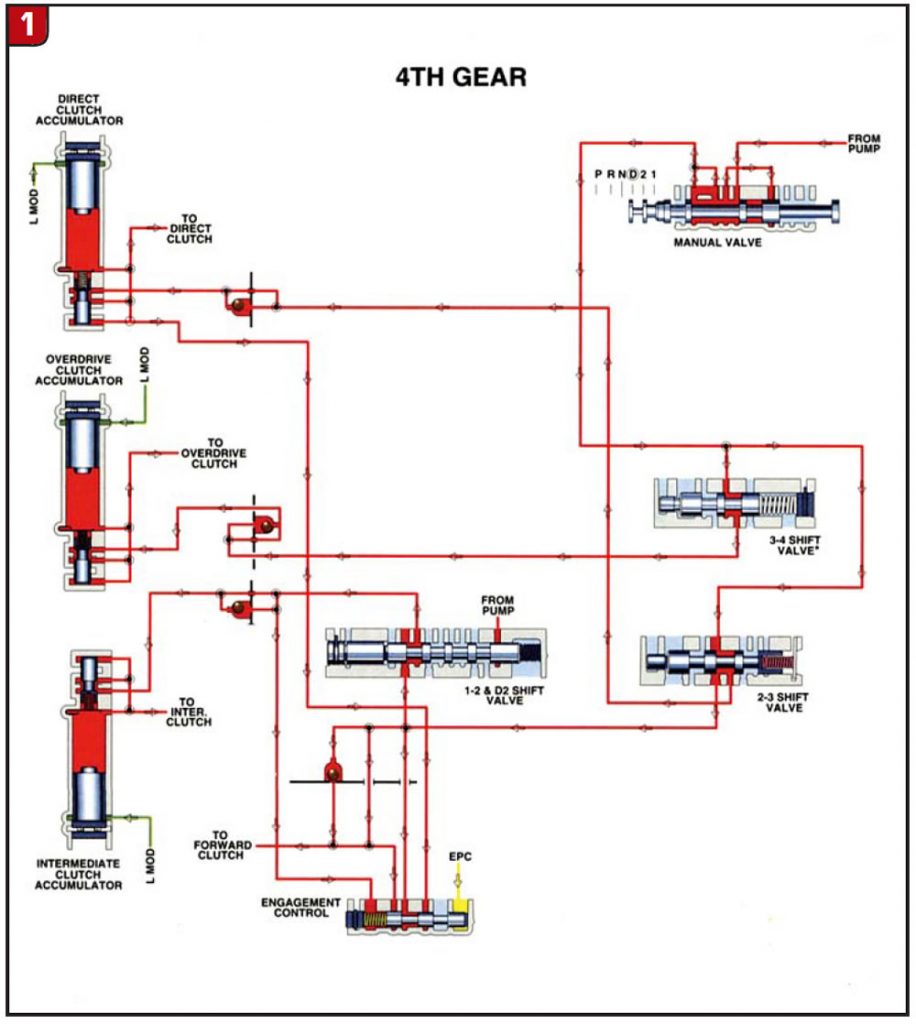

When we did this test on the 4R100 we could hear all the clutch packs apply except for overdrive. On this unit you can see the overdrive clutches, and they didn’t move at all. What we did find, though, was a lot of air escaping from around the manual valve. We found the problem. The manual-valve bore was worn. This was easy to miss because the manual valve is steel and had no signs of wear. If you look at the partial oil circuit for 4th gear in the illustration, you can see what happens. With the second partition in the valve body worn, pump pressure to the various clutch packs was being exhausted to the pan. So why did it affect only fourth? Well, the 4R100 is completely non-synchronous. When the transmission is upshifting, once a clutch comes on it does not come off. The clutch-apply piston areas are very large, so by the time the unit got to overdrive the leak at the manual valve was too great for the volume of oil needed to apply the overdrive clutch.

If you have never used the air test I described, the next time you run into a problem where it applies, try it. It takes a little getting used to but you’ll be surprised at the circuit leaks you can find. Finally, remember that just because a particular transmission type is not known for worn valve bodies doesn’t mean that it doesn’t happen.

Joe Cangelosi provides product support to retail rebuilders via the VBX support line.