TASC Force Tips

- Author: Jim Dial

- Subject Matter: Plowing

- Issue: 4L80-E & 4R100 vulnerabilities

It’s Snow Plowing Season Again!

Wintertime typically equals a parking lot full of snowplow trucks. Sometimes they represent repeat business — of the bad kind — but most of the time, new work.

I remember back in the day, living in northeast Ohio, many of the plow-truck drivers were a close-knit family of sorts, and they would refer fellow drivers to shops with which they previously had good service experiences. Of course, they also would tell other drivers where they did not get good service. The shop where I worked promised a one-day service for these trucks, which meant long hours working in a snow-soaked and rust-filled shirt (hopefully someone has invented rain gear for R&R men by now!). The snowplow trucks from that era had similar problem areas and parts that would fail, so we always kept those particular parts in stock in an effort to keep our one-day service promise.

Times have changed and the drivers have passed the plowing down to younger generations. Fortunately for the younger folk, the old trucks could not be passed down along with the job, as they are now rusted hulks in the back of local boneyards. Funny thing is, on a real quiet night, you can hear the rust trickling off those old trucks — kind of like metal rain — just a small reminder that they are still there, especially the nightmare trucks!

For some, the plow truck of choice these days is typically either a Chevy/GMC 2500/3500 series 4X4 with the GM 4L80-E transmission or a Ford F250/350 4X4 with the 4R100 transmission. When used in a plow vehicle, these two transmissions have had similar problems. Those of you who have had one of these plow transmissions on the bench are very familiar with the extreme use they are subjected to and have seen (and smelled) the results. It’s pretty bad when it is -10 F outside and you have to crack the garage door open after removing a torque converter with stinky fluid that has turned shades of blue from overheating. Other than overheated torque converters, rebuilders are accustomed to seeing anything that was plastic become a melted blob, with every bushing discolored. Needless to say, a plow-truck transmission is not a fun unit to build.

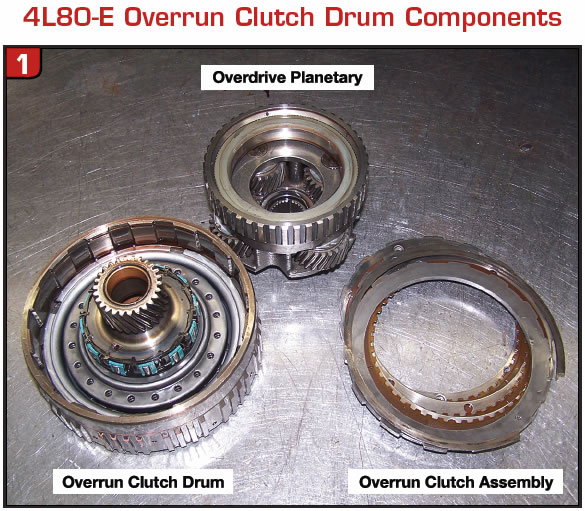

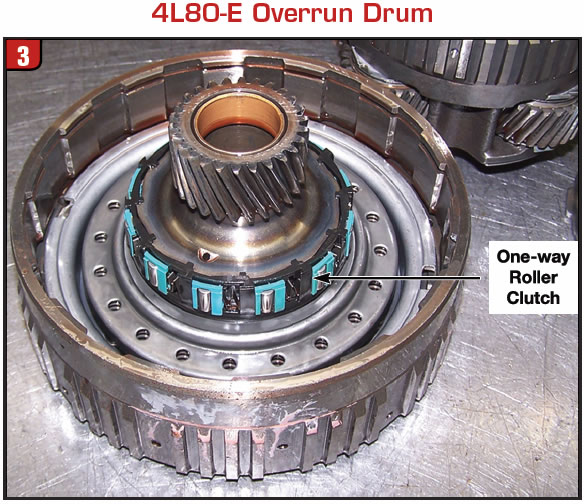

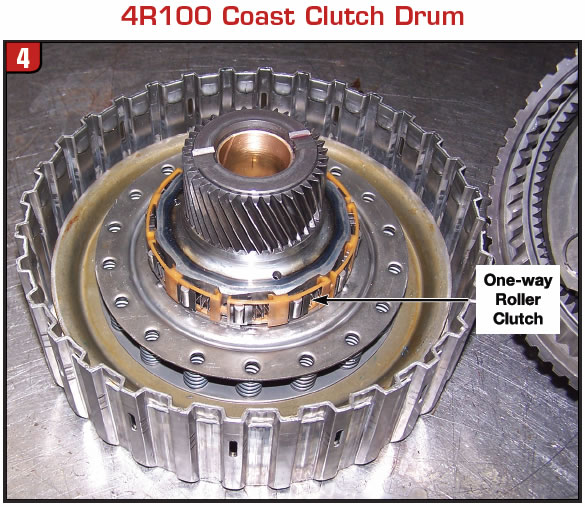

The 4L80-E and 4R100 have similar arrangements of the overdrive planetary and the overrun/coast clutch (figures 1 & 2). The overdrive one-way roller clutch that is housed inside of the overrun/coast clutch drum also is similar between the two transmissions (figures 3 & 4). On both of these units, this one-way clutch holds in 1st through 3rd gears and freewheels in 4th gear. The odd thing is that the 4L80-E overdrive roller clutch seems to fail more often than that of the 4R100 during extreme use.

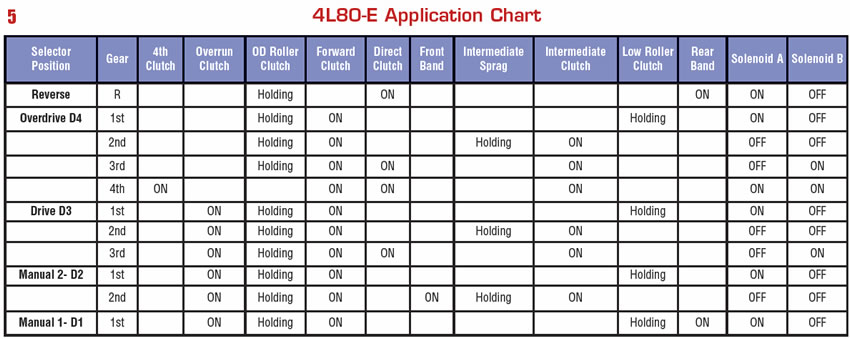

The reason for this 4L80-E failure may come from a number of different avenues. Refer to the application chart (Figure 5) and note that, in the overdrive range on the 4L80-E, the OD roller clutch is holding by itself and the overrun clutch is only on in the manual ranges, D21. Driving in the manual ranges while pushing snow will definitely help back up the roller clutch with the overrun clutch, providing engine braking and distributing the load onto the overrun clutch rather than the roller clutch.

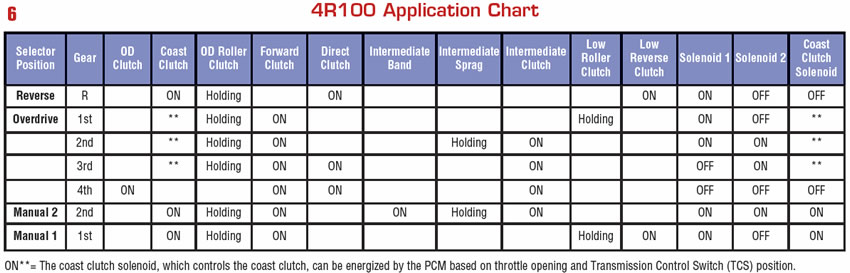

Another avenue for failure can be from overheating. Many of these vehicles have a transmission fluid temperature gauge that can be monitored to prevent overheating. During overheat, the plastic cage of the overdrive roller clutch can melt, which causes a quick failure of the roller clutch. Note that the overdrive roller clutch in the 4R100 also is holding in the overdrive range, the same as the 4L80-E, but that there is a coast clutch solenoid controlling the coast clutch (Figure 6). There also is a Transmission Control Switch (TCS) that is an input for the PCM, which controls the coast clutch solenoid and coast clutch application. This TCS also provides an overdrive cancel. In addition, the coast clutch solenoid is energized on hard throttle takeoffs in the overdrive range, which also backs up the roller clutch.

Herein lies a big difference between the 4L80-E and the 4R100 and a possible reason that the 4L80-E roller clutch fails more often than the 4R100. If the driver selects the overdrive range when they are plowing in a 4L80-E truck, the overrun clutch can’t come on to provide better holding power. But with the 4R100 in the overdrive position, the coast clutch is controlled by the PCM through the computer strategy and the TCS switch, which ultimately controls the coast clutch through the coast clutch solenoid. Also note that the 4R100 has the coast clutch applied by the manual valve in reverse, while the 4L80-E does not (figures 5 & 6). This can be very beneficial when backing up trailers and heavy loads.

In closing, it is extremely important to advise drivers of plow trucks how best to handle the vehicle during extreme use and how to use the gauges to help prevent overheat. Also, encourage using manual ranges to apply the overrun/coast clutch for better holding power, as this can definitely help prevent OD roller clutch failure. Helpful advice like this can prevent repeat business — the bad kind — and warranty issues.