R&R Tech

- Subject: Diagnosing a P0753 code

- Unit: 4L60-E

- Essential Reading: Rebuilder, Diagnostician, R & R

- Author: Richard Middleton

We sold a 4L60-E to a neighboring shop, which installed it and then brought it back to us because of a P0753 shift solenoid A code. The code would recur consistently and almost immediately when the vehicle was driven. However, the transmission would NOT go to failsafe; it would continue working fine (this is a key point).

I did a quick resistance check on the solenoid and it was good, so I thought maybe it was a connection issue. I wanted to do some amperage tests with a scope and amp clamp, but I found it difficult to get to the circuit without opening the harness (too much work). So I just did an amp test at the transmission with a test harness plugged in, connected to the battery. It was fine at 0.4 amp on the A solenoid. I checked the B solenoid for comparison and it was 0.4 also. This test is dandy but doesn’t show you a problem with the wiring, connections or computer.

The best test would have been driving it and measuring amperage on the A-solenoid wire between the solenoid and the computer, but since I couldn’t find easy access to the harness it was just too much work. I’m just too old to do that much work.

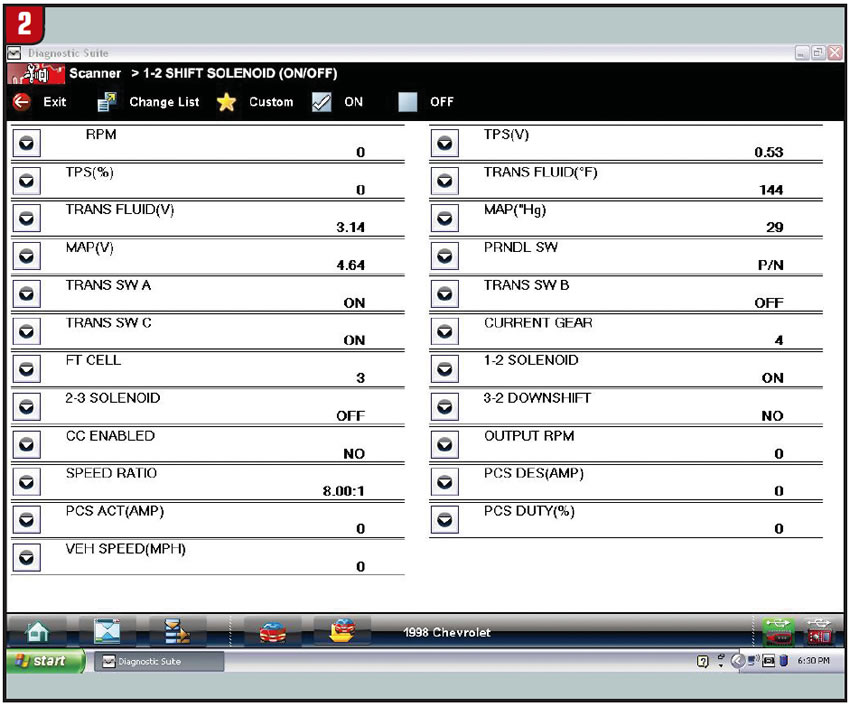

It is possible to put a jumper wire across the fuse that powers the solenoid (Figure 1) and put your amp clamp around that, but other devices on the fuse are drawing amperage as you drive the vehicle and are causing confusion. But if you do that in the bay using bidirectional controls with the scan tool, the other stuff on the fuse isn’t active, so this is the way to do it for an old guy.

So, I measured amperage at the fuse while turning the solenoid on using bidirectional controls in the scan tool (Figure 2). This loads the entire solenoid circuit just as the computer does as the vehicle is being driven. With this test showing about 0.4 amp and the comparison with the B solenoid showing the same, I was pretty sure it was a computer problem. I called up the shop that installed the transmission and they said, “Yes, the code was there before.” This would have been nice to know up front, but OK, whatever.

Now it was time for a review of the information I had:

- The computer was capable of making the correct amperage.

- The solenoid was capable of flowing the correct amperage.

- Wiring flowed correct amperage.

- All the connections flowed correct amperage.

A code was triggering but there was no failsafe. It looked like a bad computer, probably in the section that makes the decision whether to trigger the code. Usually a computer failure that generates a solenoid code would be in the driver that makes current flow. But since this transmission continued to work even after the code triggered and the computer could flow correct amperage in the bidirectional test, this made trying a replacement computer a logical decision.

After a quick computer installation, a quick reflash and a not-so-quick anti-theft relearn (a 30-minute procedure done twice because I messed it up the first time!) the problem was fixed. Anyway, with very little time invested in the diagnosis this car was repaired. I spent more time thinking about it and worrying about misdiagnosis than testing it.

Richard Middleton has been with Certified Transmission for more than 20 years and is the diagnostician at the retail location in Grandview, Mo. Over the years he has moved through the ranks from R&R technician to facility manager.