A 2007 Chevrolet Express 3500 comes to our shop with a concern of no reverse and very little forward movement. A quick check of codes reveals the following:

- P0171 Fuel Trim System Lean B1

- Po174 Fuel Trim System Lean B2

- P0218 Transmission Fluid Overtemp

- P0300 Engine Misfire Detected

- P0455 Evap Leak

- P0753 1-2 Shift Solenoid Control Circuit

- P0758 2-3 Shift Solenoid Control Circuit

- P2761 Tcc Pressure Control Solenoid Circuit

- P2a01 O2 Sensor Performance B1s2

Transmission fluid was full and burnt, so it was determined that transmission replacement would be necessary. During this replacement a new wiring harness and solenoids would be used as the transmission, and the converter assembly was a remanufactured assembly ready to be pulled off of the shelf and put into service. After the replacement was completed, the vehicle was prepared for a test drive to confirm a successful transmission replacement.

Unfortunately, that was not what happened. The vehicle now had good reverse movement and good forward movement; however, after a short test drive (which was only successful to third gear), the vehicle went into failsafe with a P0753. Starting over with recycling the ignition, the warmer the vehicle got, the shorter the time until the failsafe went into effect. Once the vehicle reached operating temperature, it went immediately into failsafe, setting code P0758.

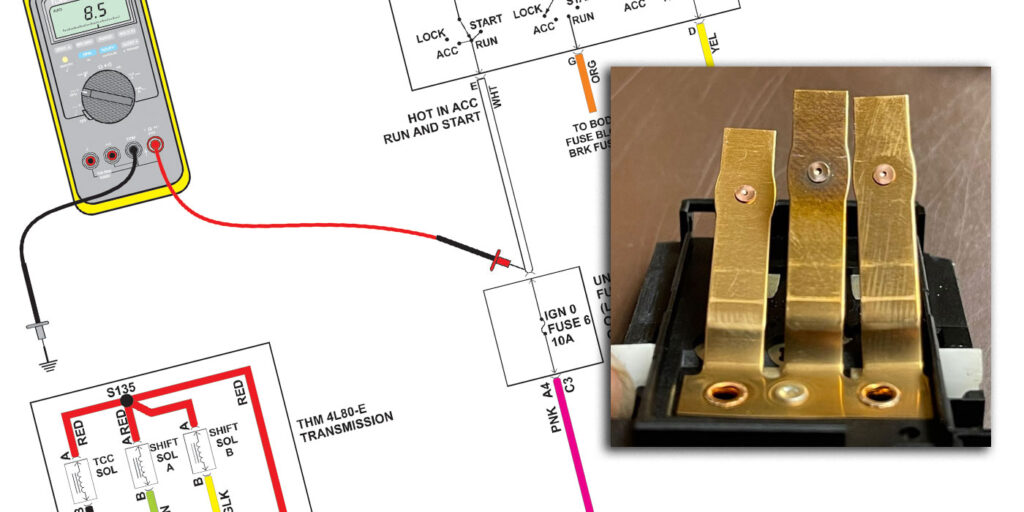

We performed a check of the transmission solenoid control wires for voltage and battery voltage was found on each control wire. Each shift solenoid was manually checked where an audible click was heard from both verifying the circuit’s ability to carry a load.

Read more columns from our Shift Pointers series here.

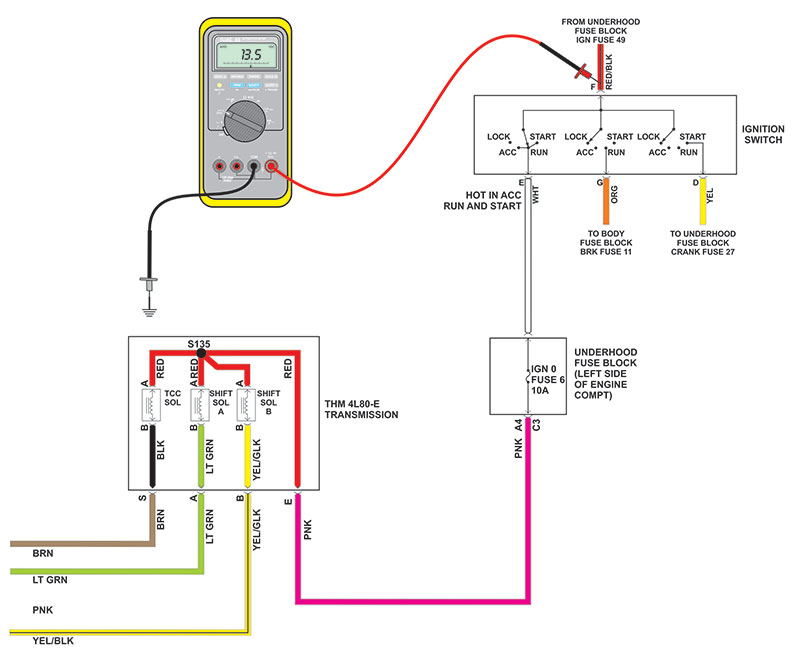

Now came time to back probe each of the shift solenoid’s control wires at the PCM (ground side controlled), to monitor voltage while a test drive is attempted. With the key on, battery voltage was recorded at both control wires (Figure 1).

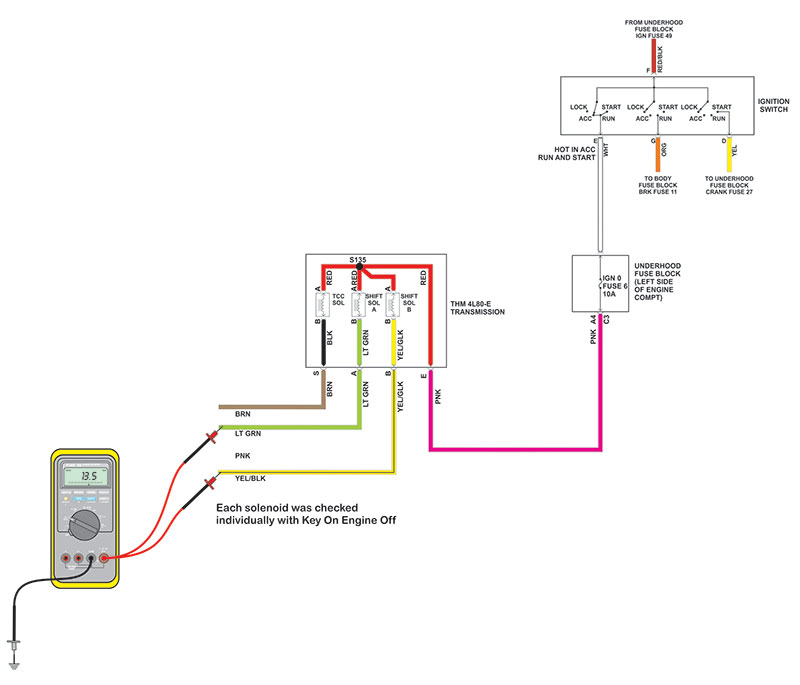

Once the vehicle was started, solenoid “A” was commanded on and “B” remained off. At this time the vehicle was left running while sitting still to allow the circuit to “warm up” to recreate the P0758. With shift solenoid A being commanded on at start up, voltage for solenoid “A” went to zero, which is proper. But, while the vehicle is running, “B” voltage began to drop (Figure 2).

The longer the vehicle ran, the lower the voltage got, indicating a poor connection/ high resistance somewhere in the circuit and resulting in a P0758.

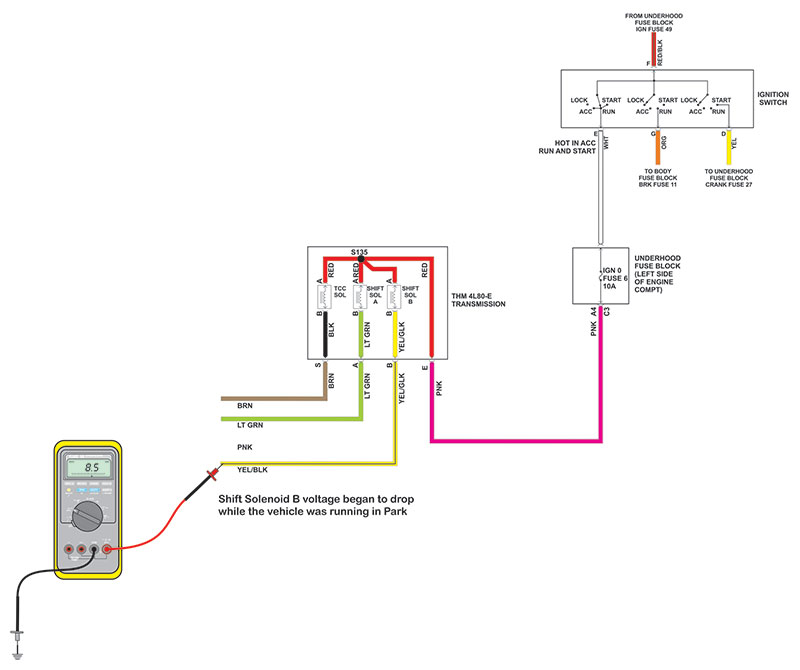

We use ProDemand here at our shop, and when entering the VIN for our Chevrolet it confirmed the presence of a 4L80E. However, on closer inspection, the wiring diagram showed a 4L60E solenoid arrangement. Care must be exercised here—we don’t want to be misled by the wrong diagram. We chose to proceed with caution and use diagrams for the 4.8 and the 6.6 to compare the circuits for shared supply voltage issues. From looking at a power distribution diagram we identified four important places to look at voltage:

- The control side of the solenoid at PCM;

- The ignition O fuse 6;

- The E terminal of the ignition switch; and

- The F terminal of O fuse 6.

The 6.6L wiring diagram with the 4L80E was the only one to properly show the solenoids that share the same supply circuit. Close examination shows this circuit to be fuse 6 IGN O. This fuse is fed from terminal “E” at the ignition switch, feeding only this fuse and very few other loads. We check the voltage at this terminal of the ignition switch, finding the same voltage readings and conditions that were observed at the control wire for solenoid “B” (Figure 3).

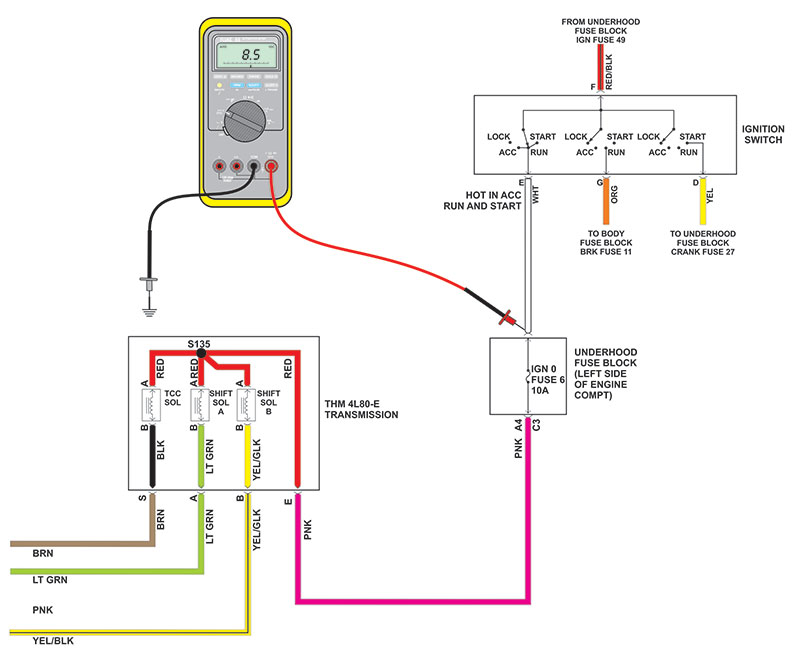

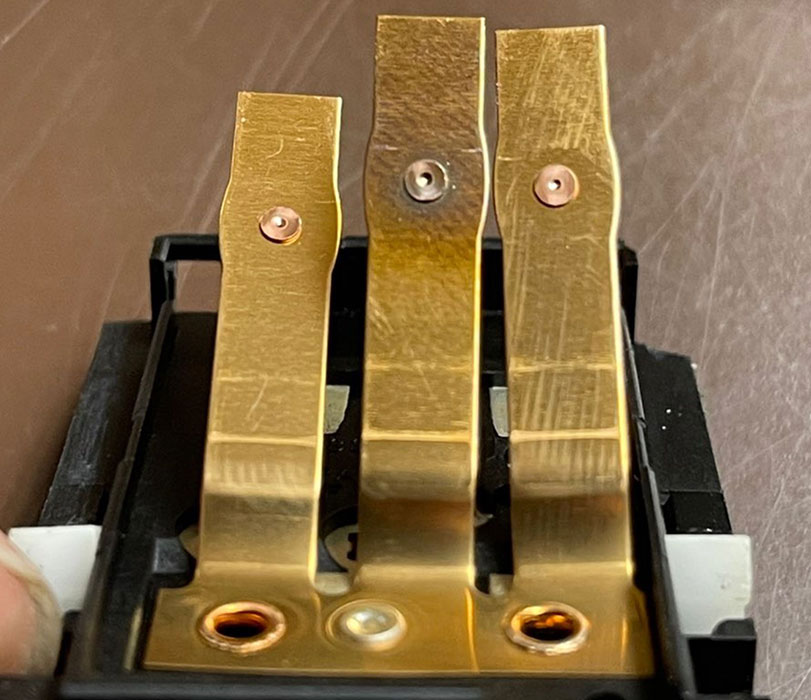

Finding the voltage dropping below system voltage as the circuit warms up was an indicator of a faulty ignition switch, as the power supply to the ignition switch was stable system voltage (Figure 4). The ignition switch was replaced with no further solenoid codes or driveability issues (Figure 5).

It is now clear that the previous transmission failure was unrelated to the ignition switch problem—but in the wrong circumstances and with the wrong decisions, this could have led to a serious mixup.

Bill Harris is the general manager of Deltrans Inc. Wiring diagrams were provided by Wayne Colonna.