TASC Force Tips

- Author: Gary Carne

A customer comes into your shop in a GM vehicle with a 4T60-E transmission that’s making a lot of noise no matter what speed the car is going but is quiet as long as there’s no wheel movement, or possibly no movement at all. You do the basic diagnostics, pull the pan and discover that the pan is full of metal, and upon disassembly you find the differential parking-gear bearing is blown. Or, even worse, a unit you just repaired a couple of months ago comes back with one of these problems.

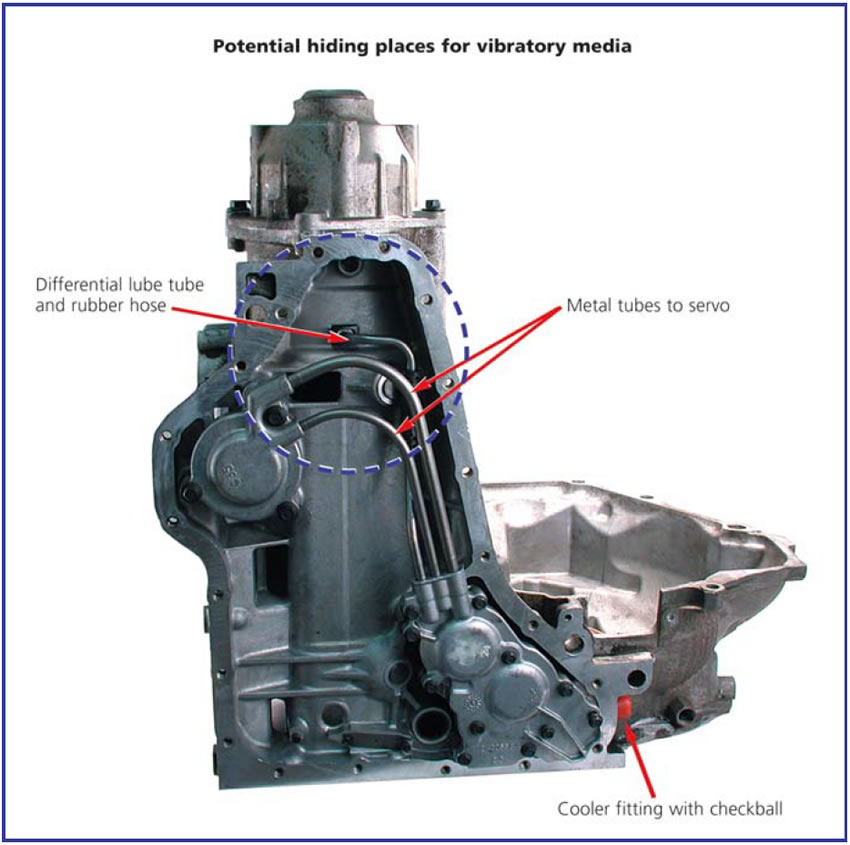

At this point you’re pretty sure the cause is a lack of lubrication in the differential area. This could be from a cooler-flow problem. As we all know, there are several areas to look at to determine the cause. It could be poor flow through the radiator and cooler lines. It could be a defective checkball in the cooler fitting. The cooler lines could be crimped or the rubber hose could be collapsed on the inside. The lube tube may have blown out of the accumulator-housing cover. The accumulator housing itself may be warped.

To make sure you cover all the bases outside the transmission, you flush the cooler in the radiator, double-check the cooler fitting in the case to be sure the checkball isn’t stuck closed, clean the cooler lines and confirm that the rubber has not collapsed on the inside. You have made sure the cooler is flowing properly through your flushing machine.

Inside, you completely disassemble the accumulator-cover assembly, lube tube, servo tubes, hose, clamps, everything – to look for possible problems that could cause lube failure. You flat-sand the accumulator cover because of known problems from warping.

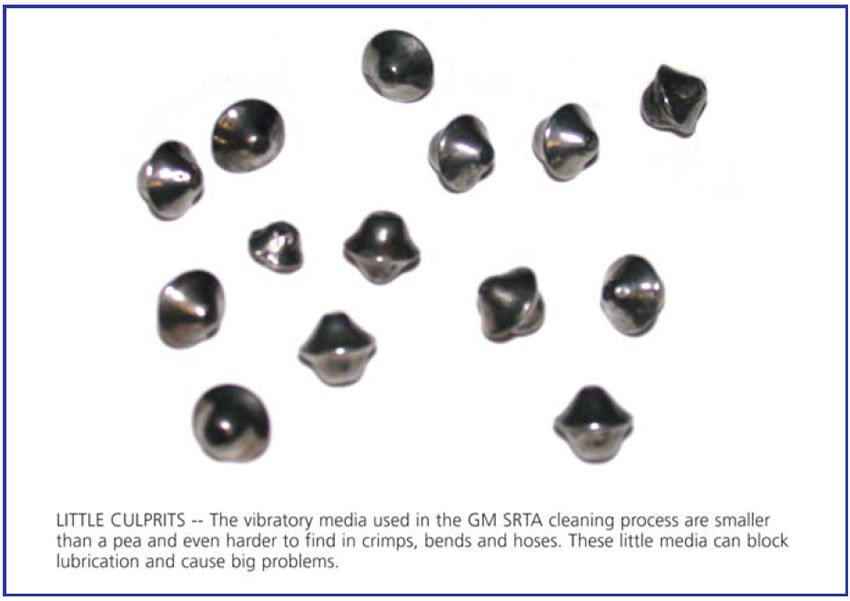

STOP! This is where you MUST verify that there is no contamination, specifically in the lube tube itself. If the transmission is a GM Service Replacement Transmission Assembly (SRTA), contamination in the lube tube may well be the “vibratory media” used in the cleaning process at the GM SRTA plants. That lube tube actually may be plugged with these media particles, which are small enough to slide inside the tube. If you don’t completely disassemble the accumulator-cover assembly, including the connecting hose and clamps, you’ll never be able to see all the small media pieces that have become lodged in the lube tube’s bends and crimps. We have seen as many as 10 of these media pieces in these lube tubes.

You may think that a strong blast of air will remove any vibratory media that may be affecting the unit. You’re wrong! Remember, air will go where oil will not. Units with this problem have “air-tested” just fine. The only sure bet is to grab a few pipe cleaners and ream out the lube tube, paying particular attention to the bends and crimps where the media pieces tend to collect. It is also recommended that you run solvent or parts cleaner through all lube tubes to verify flow.

Upon reassembly make sure you have secured the lube tube properly to the accumulator cover and to the transmission case. We also have seen media in the lube holes for the differential that feed the differential from the lube tube.

Gary Carne is the technical director for Freeway Transmissions Inc. and a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians.