Dana offers Spicer performance differential covers

Dana Inc. offers Spicer nodular iron performance differential covers that it says are engineered for off-road performance and help protect the intricate differential parts on a vehicle. The differential covers also have the added advantage of coming pre-primed from the factory so that enthusiasts can customize the color of their differential cover, Dana says. “Differentials are

Sonnax releases splined stub and sleeve kits for performance vehicles

Sonnax highlights its new aluminum splined stub and sleeve kit, which the company says can reliably drive power from the engine and transmission to the differential in modern muscle cars and custom street rod/hot rod vehicles. These kits make it easy to build, balance and service a rugged performance driveshaft for non-slip-yoke applications, since the

GFX announces 47-teeth differential gear for Toyota transmissions

GFX has introduced a new 47-teeth differential gear for Toyota transmissions, including the U660E. According to the company, the product is designed to replace years 2007 and on.

Alto adds friction and steel clutches for ZF differentials

Alto has introduced a new line of friction and steel clutches for ZF differentials, model years 2011 and on. The friction clutches feature Alto’s K2 high-energy material.

ATC Drivetrain Acquires UK Heavy-Duty Transmission Remanufacturer

The acquisition represents a new market for ATC as it enters the commercial vehicle segment.

Differential Look-Up

Today, we’re showing you how finding and ordering the right differential parts is faster and easier than ever. Transtar offers more than 1,200 driveline parts and products covering more than 150 different differential series. Whatever’s in your shop, chances are, we can help you fix it. We’re talking about slip yokes, u-joints, driveshafts – everything.

Transmission Tech: Toyota AWD Differential Bearing Noise

In this episode, Mike Riley discusses specific noise issues in certain Toyota applications.

Different Designs for Different Diffs

We work on drivelines for a living. The transmission makes the torque created by the engine into a usable form through steps (gears), the lowest of which transmits the most usable torque, and the highest of which can transmit the most rotational speed. The transmission sends that power to a third member or rear end, or in front-wheel drive, a rear end contained inside the gear box, without a drive shaft. The rear end now transmits the power to the drive axles and wheels, making a 90° turn through the ring and pinion gears. Transmission gears and the rear-end ratios are matched to the power curve of the engine to provide the most fuel-efficient speeds. The ring gear is mounted to a differential carrier, or in many front-wheel-drive transmissions, a planetary-type of carrier. The differential is contained inside the carrier.

Dodge 9.25-Inch Differentials, and Why You Can’t ‘Tool’ Around

Repairing differentials is an important source of income for every shop. Many shops had shied away from what is really a simple repair but are now finding that there is not enough work to be had just repairing transmissions. Beside replacing worn or damaged gear sets, you can offer ratio changes that will increase the performance level or lower fuel consumption on many vehicles as an elective purchase for customers who have no problems with the differentials in their vehicle.

Prime Cuts – New Technology for Ring and Pinion Gears

Every shop in this industry is working hard to increase the volume of its business and the percentage of profit. Repair and diagnosis of automatic and manual transmissions and transfer cases are generally deemed to be the core of the business. Clutch replacement, driveshaft work, CV joints and wheel bearings are common sale items, but many shops neglect differential work as a profit center.

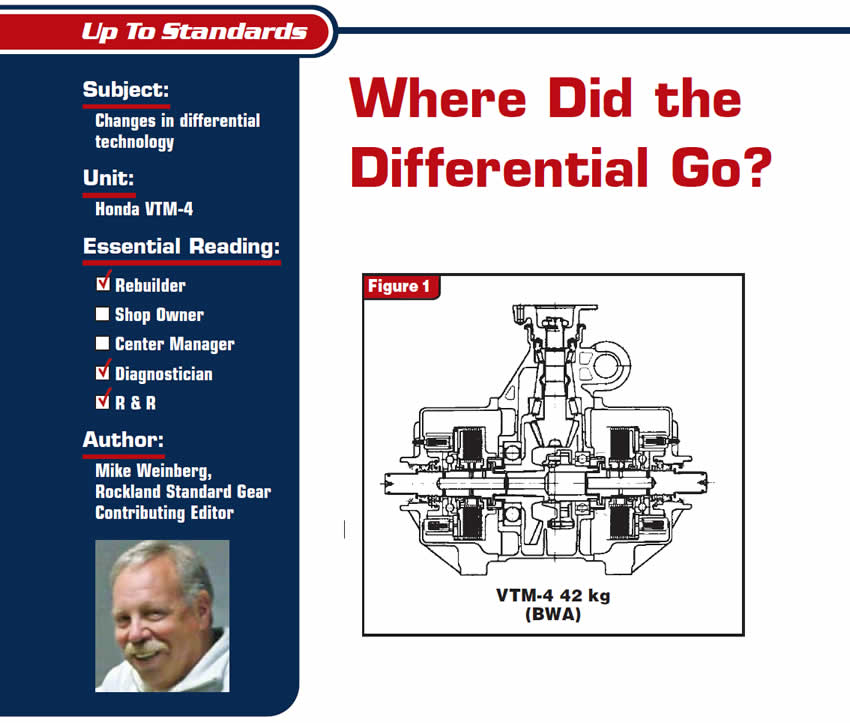

Where Did the Differential Go?

Traditionally, all motor-vehicle final-drive elements (differentials, or rear ends) have consisted of a ring and pinion, with the ring gear mounted on a differential carrier. The differential carrier contained a set of side gears splined to the drive axles and a set of pinion gears allowing the side gears to rotate at different speeds.

The differential is necessary because the outside wheel on an axle has to cover more distance in a turn than the inside wheel. This means that the outboard wheels must rotate faster than the inboard wheels; hence, the “differential” in wheel speed.

The Rear Up Front

With four-wheel-drive and all-wheel-drive vehicles being produced in such huge numbers, these trucks and cars have become an important source of repair business for our industry. Transmissions and transfer cases are now a huge part of the repair and reman market. It is also obvious that these designs use both front and rear differentials to transfer power to both sets of drive axles. This has effectively doubled the amount of differential work that will find its way to the repair shop.