BMW Front Differential Repair Kit

LBM Autoparts has introduced a repair kit for the BMW front differential used in 2004-later X-drive models. These BMW X-Drive models have a common problem with noise issues, and the complete unit is costly. Therefore LMB decided to develop a repair kit with all the parts needed to rebuild the differential properly. The kit is

Dana Introduces Spicer Select 404 Ring and Pinion Gearing

Dana Incorporated has introduced Spicer Select commercial vehicle 404 ring and pinion gearing. Ideal for post-warranty vehicle service, these parts are manufactured with the same quality control measures as genuine Spicer gearing and are backed by an 18-month, 100,000-mile warranty. “Spicer Select 404 gearing will help service technicians rebuild differentials with confidence,” said Bill Nunnery,

Differential Basics

Differential is a term that stems from the word difference, and it applies here because of the difference in distance traveled by the vehicle’s drive wheels in a turn. In a straight line both wheels and, therefore, both drive axles travel at the same speed. When the vehicle is entering a turn, it is obvious that the inside wheel will travel less distance than the outside wheel during cornering. If the drive axles were hooked directly into the differential carrier, to which the ring gear is bolted, the driving wheels would crow-hop and bind up in the turn, and the tires would take a lot of excess wear and heat.

Understanding the Myths and Mysteries of Differential Repair

One of the simplest and most-profitable repairs a shop can perform is to the differential or third member. Yet many shops do not understand the fine points of this work and turn it away.

Different Differentials: What is the difference?

Differential comes from different. In automotive terminology the differential is a component of a drive axle – either rear-, front-, or four- or all-wheel drive – that permits the axles to rotate at different speeds as the vehicle makes a turn. In a turn the drive axle toward the inside of the turn will have to rotate less than the axle on the outside of the turn because of the larger arc covered by the outside wheels.

Prime Cuts – New Technology for Ring and Pinion Gears

Every shop in this industry is working hard to increase the volume of its business and the percentage of profit. Repair and diagnosis of automatic and manual transmissions and transfer cases are generally deemed to be the core of the business. Clutch replacement, driveshaft work, CV joints and wheel bearings are common sale items, but many shops neglect differential work as a profit center.

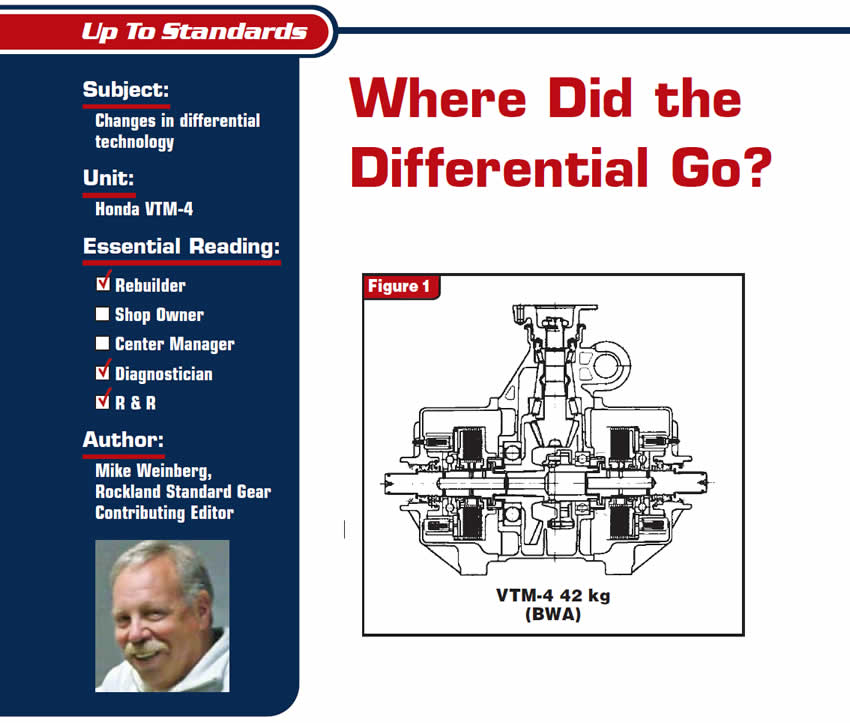

Where Did the Differential Go?

Traditionally, all motor-vehicle final-drive elements (differentials, or rear ends) have consisted of a ring and pinion, with the ring gear mounted on a differential carrier. The differential carrier contained a set of side gears splined to the drive axles and a set of pinion gears allowing the side gears to rotate at different speeds.

The differential is necessary because the outside wheel on an axle has to cover more distance in a turn than the inside wheel. This means that the outboard wheels must rotate faster than the inboard wheels; hence, the “differential” in wheel speed.

Good Vibrations: 4T60-E Differential Problems

A customer comes into your shop in a GM vehicle with a 4T60-E transmission that’s making a lot of noise no matter what speed the car is going but is quiet as long as there’s no wheel movement, or possibly no movement at all. You do the basic diagnostics, pull the pan and discover that the pan is full of metal, and upon disassembly you find the differential parking-gear bearing is blown. Or, even worse, a unit you just repaired a couple of months ago comes back with one of these problems.