TASC Force Tips

- Author: Ed Lee

The 4T65-E was introduced in 1997 in several vehicles equipped with the supercharged 3.8-liter engine, and some non-supercharged 3.4- and 3.8-liter engines. It was considered to be the big brother to the 4T60-E transaxle.

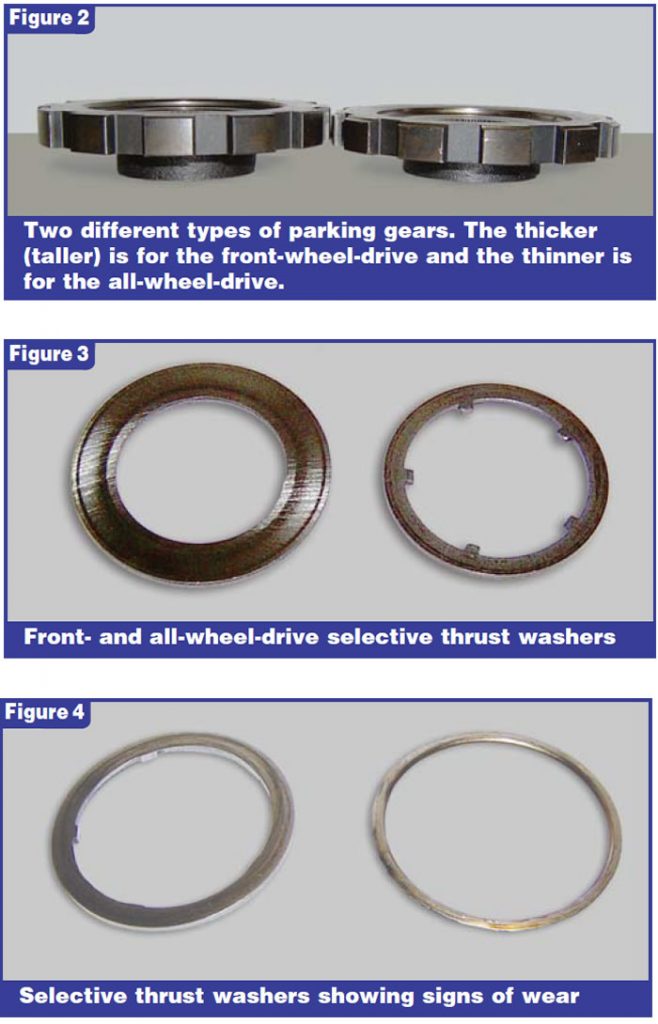

The differential for the front-wheel-drive 4T65-E rests between the final-drive ring gear and the final-drive housing. Since the differential is free to move between these two members, its end play must be regulated. The parameters for the end play are a minimum of 0.005 inch and a maximum of 0.025 inch, and final-drive selective thrust washers are used to adjust this measurement. There are 10 different selective thrust washers ranging from 0.055 to 0.095 inch thick, and they are installed just as they have been since the introduction of GM’s first front-wheel-drive transaxle, the 125. In 1999 an all-wheel-drive version of the 4T65-E was offered in the 3.4-liter Montana.

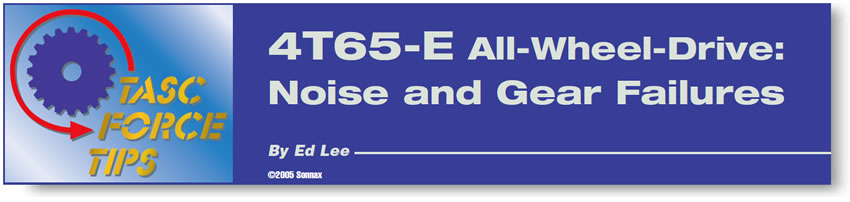

Except for the differential, the all-wheel-drive 4T65-E transmission is the same as the front-wheel-drive. The drive gear for the all-wheel-drive section is mounted to the differential housing near where the reluctor was mounted on the front-wheel-drive differential.

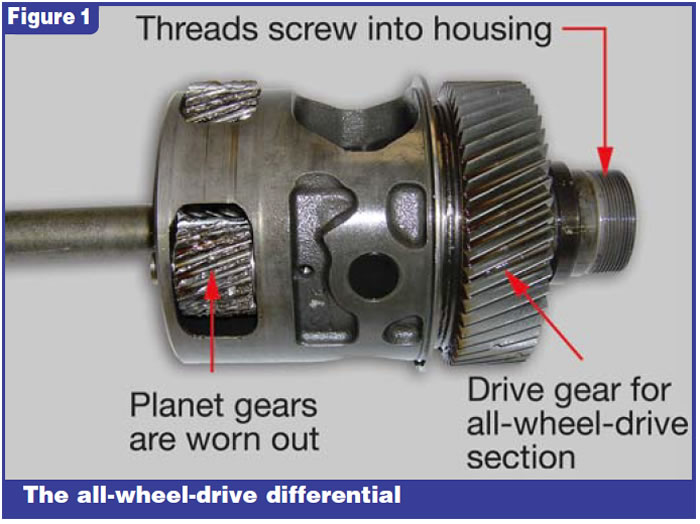

When power is transmitted through gear-to-gear contact, the end play of the gears must be as close to zero as possible. For this reason, the differential of the all-wheel-drive 4T65-E is attached to the transfer-case housing. The end of the differential is threaded, and a large nut secures the differential to a bearing in the housing. Since the differential is affixed to the housing, the end play of the mating parts must be adjusted inboard of the differential. This is done by moving the selective thrust washer to a new position, at the drive end of the differential. Material is removed from the parking gear, and the selective washer is sandwiched between the parking gear and the final-drive sun gear.

There are 21 different selective washers ranging from 0.061 to 0.105 inch thick. The end play is checked in the same manner as the clutch clearance is checked in the rear-wheel-drive Chrysler overdrives. If you follow the directions correctly, you will end up with an end play between 0.020 and 0.024 inch. The selective thrust washers for the all-wheel-drive transaxles do not have a full-circle inside diameter like the front-wheel-drive washers.

The five locating tabs on the all-wheel-drive washers only center the washers on the sun-gear shaft. The washers are free to rotate on the shaft, and since the shaft is considerably harder than the washers, they wear quickly. The material that the shaft removes from the washers passes through the gears of the differential and causes damage similar to that seen in Figure 1. At this point, replacing the selective washer with an OE replacement is your only option.

However, if you are really lucky, you may find a front-wheel-drive parking gear that is the same thickness as the combined thicknesses of the selective washer and the all-wheel-drive park gear. Another alternative is to find a front-wheel-drive park gear that is thicker than the washer and gears combined and have it machined to the proper thickness. Either way will work, and you will be safer than using the OE washer.

Special thanks to the crew at Deltrans for their assistance in preparing this article.

Ed Lee is a Sonnax Technical Specialist and a member of the TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians. ©2005 Sonnax