Tech to Tech

- Subject: Engine miss; PCM not receiving No. 4 coil confirmation signal

- Vehicle Application: 2003 Toyota Corolla

- Essential Reading: Diagnostician

- Author: Jeff Bach

Diagnostics takes a complicated turn when a supposed wiring problem turns up empty

“It’s the computer. Just reprogram it, OK?” I hear Angel say after she hangs up the phone.

“They all just want to guess and hope it’s a sure fix, but without testing it’s like throwing a dart at a board with your eyes shut and hoping it hits the middle,” she continues.

“My guess is that there’s been a little more done than parts darts,” I reply.

So the car in question gets delivered to the shop and the reprogramming begins. The electronic control module (ECM) is reprogrammed and – wow, bet you guessed – it is still running rough with a miss. I call the guy and let him know it’s still missing. He gives me the complete rundown on what has been done and wants to know if we can figure out what’s causing the miss. He thinks it has to be in the wiring, since he has already replaced the injectors, the coils and the ECM.

It’s easy to see how one can get this deep into the woods, considering the progression of technological advances that modern automobiles have undergone. The ability of the powertrain control module (PCM) to precisely control vehicle ignition systems and monitor their response is almost artistic. There was a point when ignition and fuel-system problems could be diagnosed quickly and accurately by an experienced and discerning eye. Both the primary and secondary systems were subject to exposure of their most-intimate parts with nothing more than a screwdriver as an examining tool. Fuel trim was attainable with a quick snap of the throttle and a bushy pair of eyebrows. This made diagnosis so easy anyone could do it, and no one charged for it.

Then came the rise of corporate America, and the Ignition System Privacy Act was born. Ignition-system primary circuits were the first to get their rights, which came in many forms of transistorized triggering systems. Their diagnosis now became limited to “mechanics” trained by the dealers and those independents who were able to obtain the knowledge in whatever creative ways were at their disposal. Of course, there were some who could get by on good guessing, but most of them went into sales.

The screwdriver soon gave way to “the diagnostic computer.” These machines were so sophisticated they could not only look into the primary ignition system but also could even tell whether your alternator belt was slipping. About this time, fuel systems began demanding equal rights under the privacy act, and computerized fuel controls took effect. Diagnostics was fast becoming a specialized field, and people became willing to pay to have their cars hooked up to one of those “big diagnostic computers.”

These futuristic diagnostic dinosaurs became extinct even before they reached the year in their title. One of the main reasons they became nostalgic space “taker uppers” in storage facilities was the advent of the distributorless ignition system (DIS). This system required the next generation of diagnostic equipment to be brought into existence in the form of the handheld scan tools.

Along came onboard diagnostics (OBD-I), and onboard computers could now control, monitor and report problems to technicians in the form of trouble codes, which usually contained the name of the failed part in their title. Diagnostics started to again become so simple that many parts chain stores were now doing it free. DIYers could once more fearlessly open their hoods.

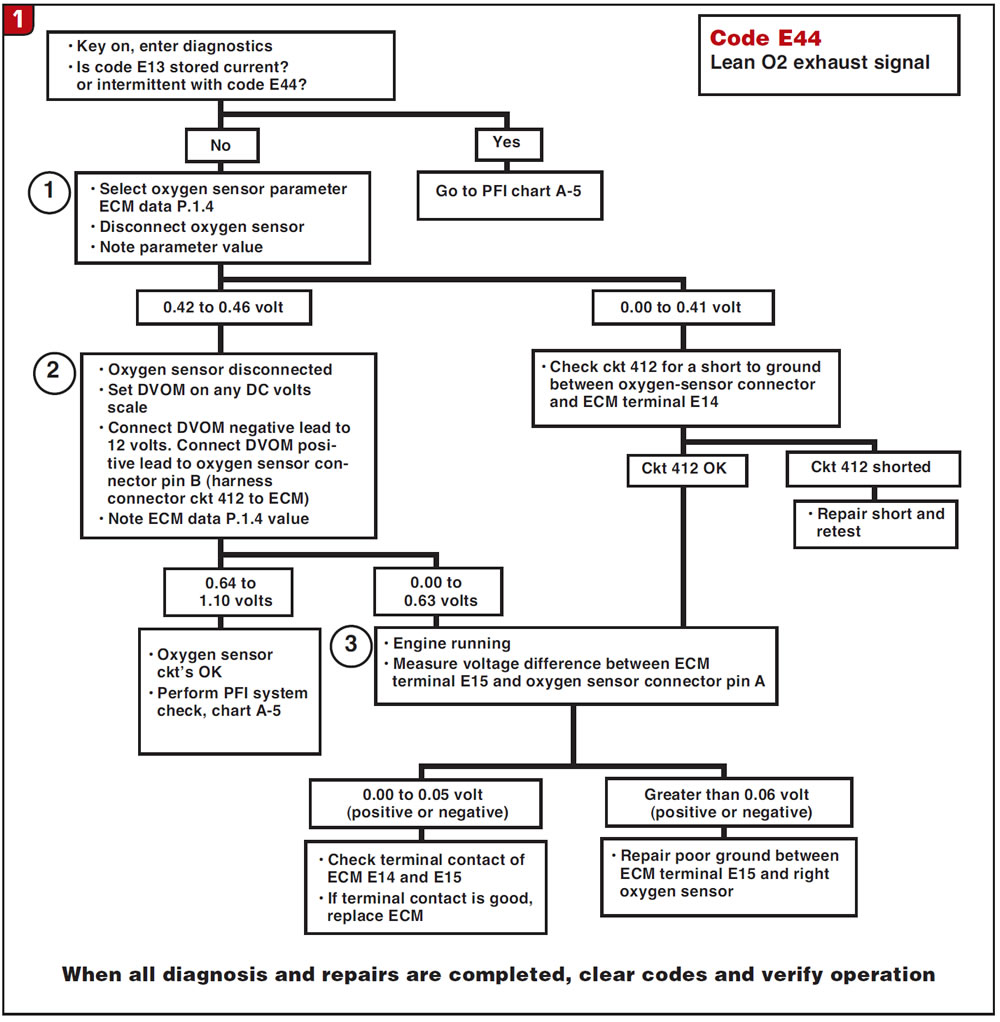

About this time the government stepped in, and along came OBD-II. This standardized the code system so that all manufacturers had to use the same numbering system for trouble codes, and it gave access to generic data to even aftermarket scan tools through a standardized connector. This was a boon of an economic-stimulus package and gave anonymity to the much-exposed failed parts usually mentioned in prior OBD-II trouble-code descriptions (Figure 1).

This was a simple three-step process on the chart, and there was a 50/50 shot that either the O2 sensor or PCM would fix the problem.

Step up a few years into OBD-II, and now a lean-O2-signal code – say, a P0171 – means doing a diagnostic dance through fuel supply, regulation, delivery, mechanical, vacuum, electrical contacts, mass air flow (MAF) and induction-system testing, concluding in anything but a bad O2 sensor.

With this bureaucratic shuffle, and with diagnostic systems we now use in place, there seem to be more and more Catch 22s ending up in the shop that are traced back to a part that has already been tried or a fix that ends up being a two-part combination.

This particular 2003 Toyota Corolla came to my friend’s shop with a simple miss and a code for the No. 4 coil confirmation signal not being received by the PCM. The first part tried was a coil from the dealer. With the same code coming back and the engine still missing on the same cylinder, more testing revealed that the injector for that cylinder was not operating, and another was substituted. This resulted in no change, and another coil was tried, then switched to another cylinder. Injectors were switched around, and then a PCM was ordered and the car was sent to us for programming. My friend assured me that he wanted nothing further to do with the car and told us to find the problem.

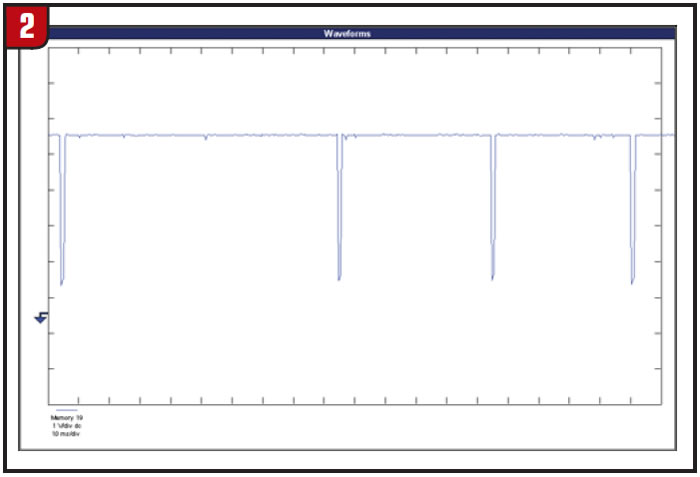

I started with a scope, looking at what the PCM was looking at to see why it was setting the code. I got the waveform in Figure 2.

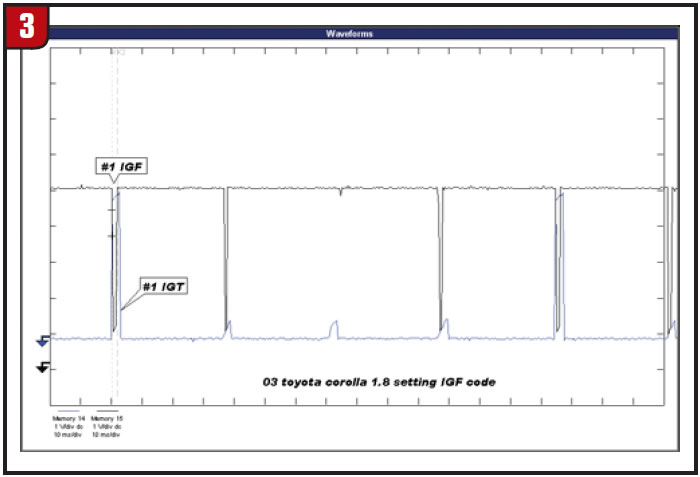

This shows the IGF signal, which is monitored by the PCM. It uses one circuit to monitor all cylinders, while each cylinder has its own trigger signal. Triggering from the No. 1 signal, proper operation can be seen in Figure 3.

The gap indicates the missing No. 4 IGF signal. According to the description, the IGF is supposed to indicate that the cylinder has had a spark event occur. Everything that I read suggests that it is supposed to occur at the time the primary current cuts. My research has shown me that this is, in fact, not the case.

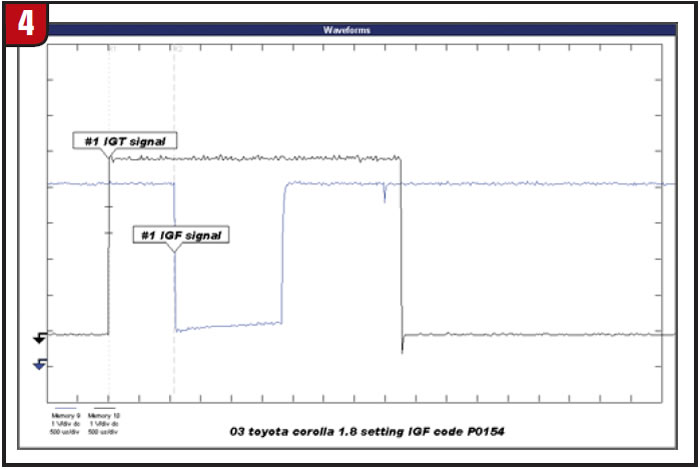

As you can see from Figure 4, 1 millisecond (mS) after the IGT or primary-circuit trigger signal begins, the IGF signal begins 2 mS later and the IGF ends nearly 2 mS before the secondary event takes place. It appears to me that it, in fact, monitors the coil primary-current build ramp for – ahem – irregularity.

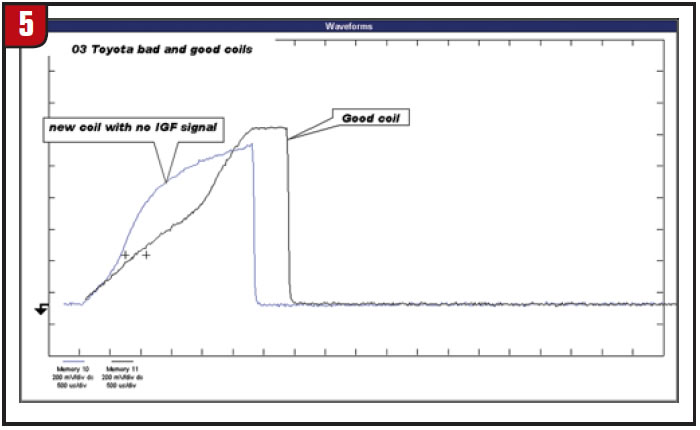

Figure 5 shows the primary-current ramps from the working factory coil and the new but not working (that is, not sending the IGF signal) aftermarket coil. Notice that the difference in the coil ramps occurs almost exactly where the IGF signal happens.

No wonder my friend had so much trouble with this one. I suspect he’s neither the first nor last technician to be caught in this diagnostic dilemma. He ended up going through a multitude of coils before finding one that would both create a spark and send an IGF signal to the PCM. This poor guy got the first two coils from his local Toyota dealer and the second two from different aftermarket suppliers. The good news was that the Toyota dealer smilingly refunded him for the non-functioning coils.

“Well,” I say to Angel, “at least it wasn’t the ground this time.”

Jeff Bach is the owner of CRT Auto Electronics, an ASA-member shop in Batavia, Ohio. For more information on this topic, contact Bach at (515) 732-3965. His e-mail address is [email protected].

This copyrighted article is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive-service and repair professionals, visit www.ASAshop.org or call 800-272-7467.