A 2005 Tundra with a 4.7L engine powering an A750F transmission arrived at EDCO Transmissions with a complaint of slipping and engagement problems. Anthony checked the vehicle and found multiple fault codes stored for solenoid performance problems. When the pan was dropped, it revealed internal problems existed as the pan was filled with excessive debris. Instead of having it rebuilt, the owner opted to replace the transmission with a salvage yard unit. Once it was installed, the codes were cleared, and the truck was delivered to the owner after a short road test.

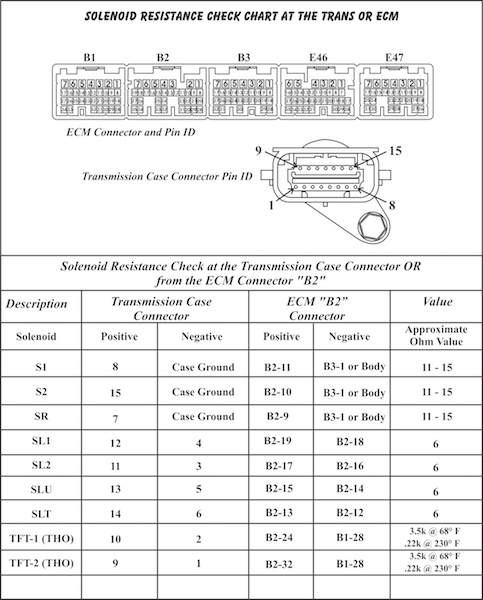

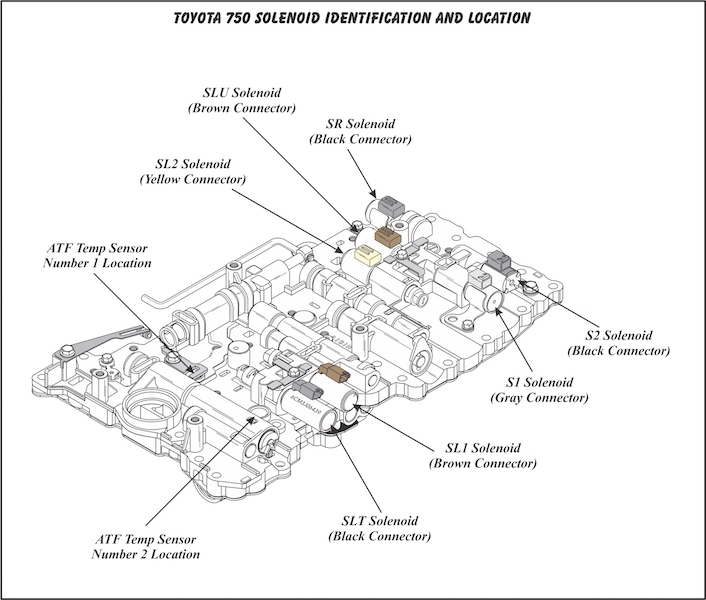

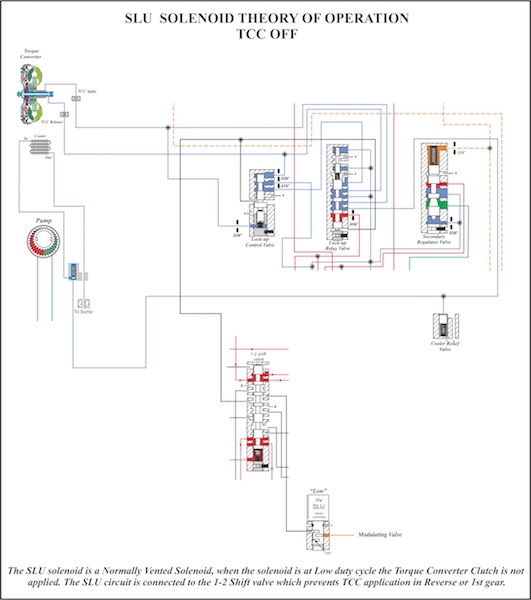

The owner returned after a few days with a complaint of the MIL coming on but stated that the transmission seemed to be working properly. When the vehicle was scanned, a P2757 code was pulled which is a solenoid performance code for the SLU (TCC) solenoid (figures 1 and 2). Anthony noted that this was also one of the original codes stored prior to unit replacement but did not return on the initial road test after unit replacement.

The code was cleared, and the truck was road tested. The transmission and converter clutch seemed to be functioning properly. It was only after an extended road test at highway speeds that the MIL came on. The scanner once again pulled code P2757 even though the converter clutch seemed to be holding and functioning properly. The pan was dropped, and no evidence of any internal problem was seen so it was decided to remove the unit and replace the converter to no avail. Then the valve body was swapped out and the same problem existed. A new SLU solenoid was installed on the original valve body and then re-installed, but the problem remained.

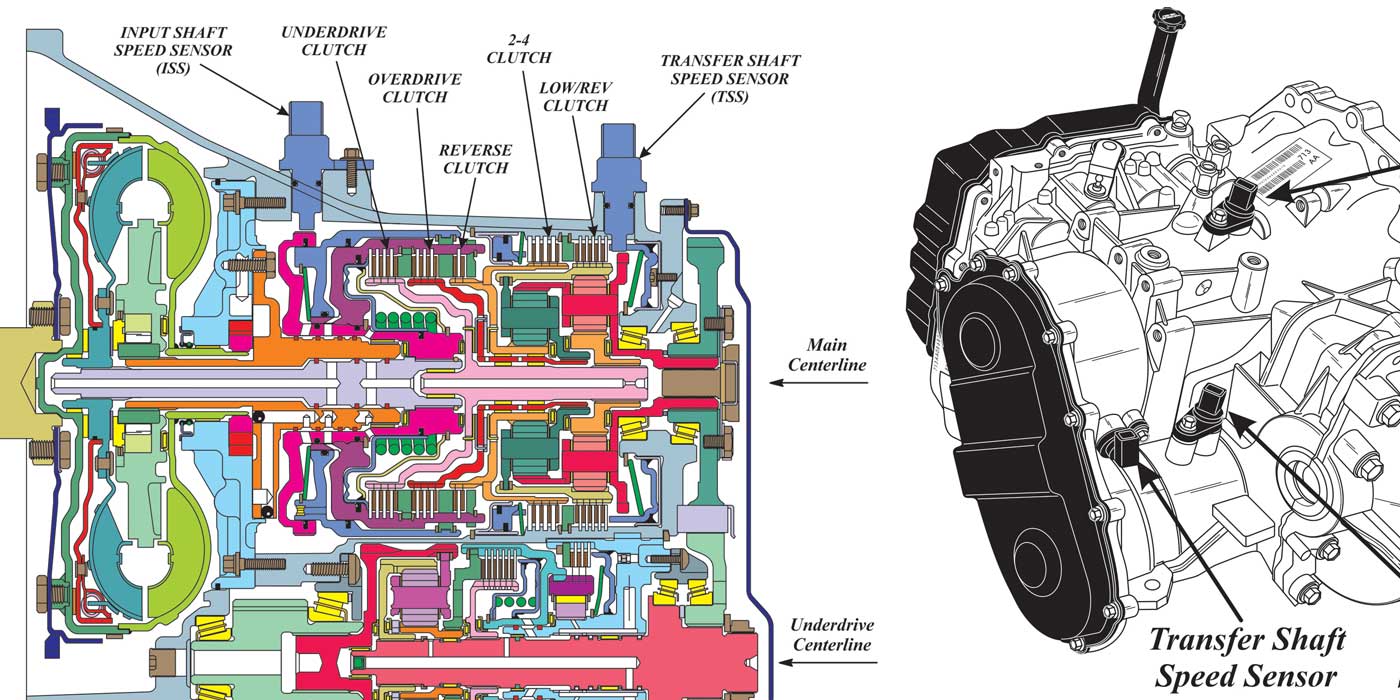

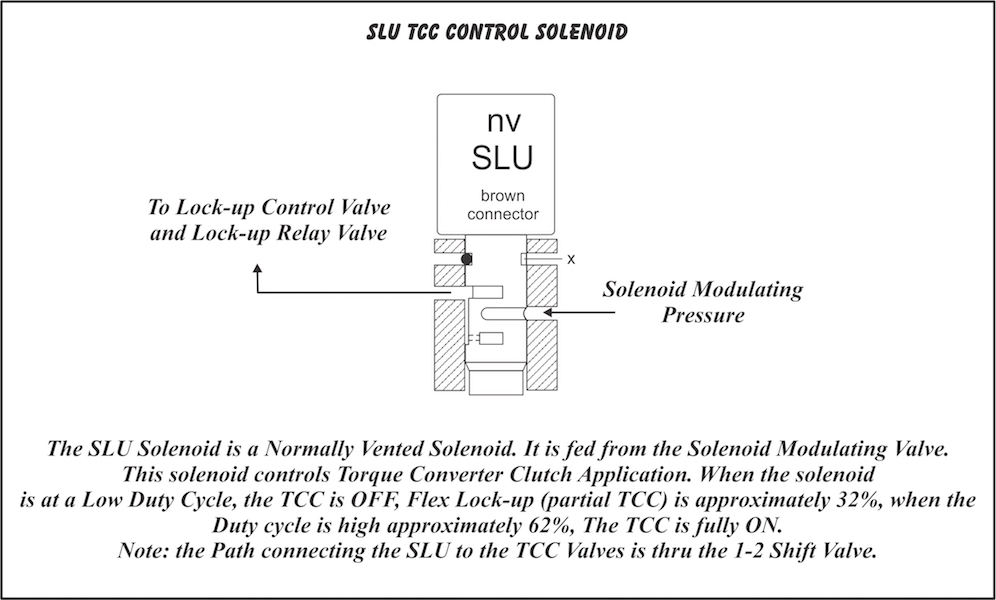

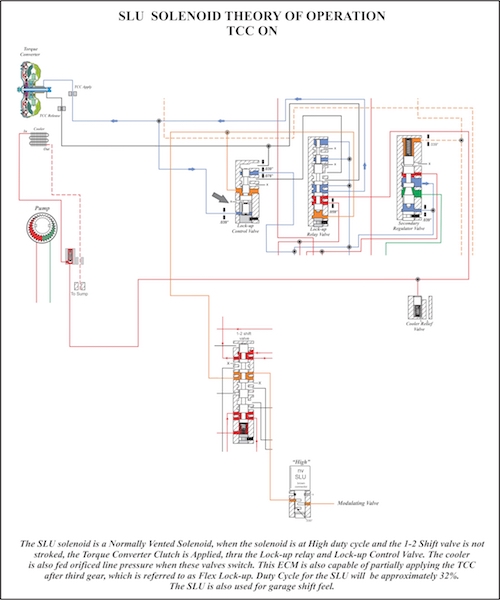

Although converter shudder was not in the description, it was confirmed that the shop was using the factory fill ATF type W/S fluid. And this is a good point to remember as this fluid is known to degrade at around 40k. Once degraded, the transmission may develop a converter clutch shudder during “Flex Lockup” at speeds between 32 and 42 mph (figures 3 and 4). Speeds above 42 mph when in 4th and 5th gear, the shudder is gone.

Since this problem usually takes place during flex lockup, it may also be noticed that when moving the selector into the “S” or “4” position and/or driving the vehicle under harder acceleration, the shudder disappears. This is because flex lockup is not commanded during these times. Often times, by replacing the fluid with new W/S fluid, this flex lockup shudder is eliminated. With knowing that this transmission was filled with factory fluid, it eliminated the possibility of a converter clutch apply the ECU did not like. It was then suggested to electrically test the signal.

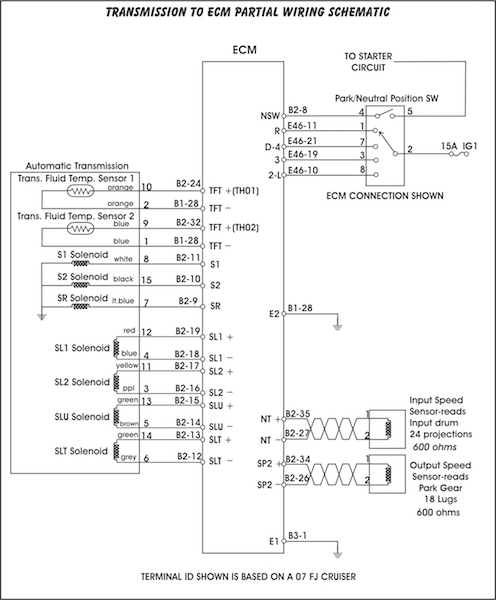

Anthony put a voltmeter across the SLU solenoid + and – wires (figures 5 and 6) to check for approximately 3.5 volts when flex lock-up was commanded, and 7.0 volts when the scanner showed lock-up was on at speeds over 45 MPH. Everything was looking good and holding at 7.0 volts as expected until the voltage reading suddenly became erratic and fluctuated after extended driving at highway speed. Then the MIL came on even though no TCC slip seemed apparent.

This would seem to indicate a faulty ECU rather than wiring or connector issues. In fact, vehicles that use the A750 family of transmissions experience harness connector problems usually due to a compromised weather pack seal. The Internal Harness for 04-4Runner and Land Cruiser for example can be purchased using part number 82125-35130 while the 05-Sequoia, Land Cruiser, Tundra, and Tacoma use part number 82125-35150. When the wiring or connectors are compromised, the ECU sets electrical codes very quickly. At this point in the diagnostics, Anthony went ahead and replaced the ECU which resolved the persistent return of code P2757.