Technically Speaking

- Subject: TCC-solenoid malfunction

- Unit: Toyota A-340 series

- Vehicle Application: 2000-04 Tundra V-8

- Essential Reading: Rebuilder, Diagnostician

- Author: Wayne Colonna, ATSG, Transmission Digest Technical Editor

DTC P0770: solenoid-E fault

I am sure by now that most shops out there have run into the pesky P0770 “Solenoid E Fault,” on some type of Toyota or Lexus vehicle, that has given you the runaround. ATSG senior technical consultant Jim Dial and I have spoken about this on numerous occasions, since it is a very common problem on our tech line. Jim did a bit of investigating, and this is what he discovered.

To begin to diagnose this code let’s start with its real definition. P0770 refers to a functional fault with solenoid E, the torque-converter-clutch solenoid. Many shops have misinterpreted this code as an electrical-circuit fault. P0773 is an electrical-circuit fault with solenoid E, as in the solenoid, internal or external harness, loose connections etc.

Now that we know what we are diagnosing, let’s take a look at the area of focus. First, the definition is pointing to a functional fault with solenoid E. The vehicle we are referring to is a 2000-2004 V-8 Tundra that has the A-340 series transmission. The TCC solenoid on this type of transmission is a typical on-off normally open solenoid. The TCC solenoid is turned on when the TCC is applied; solenoid pressure strokes the TCC relay valve, which drains the release pressure on the front side of the TCC piston. When the valve is stroked it then allows regulated line pressure/secondary regulator pressure to apply the clutch. Refer to ATSG bulletin 03-28 for a more in-depth look at the hydraulics involved with TCC application.

So, the first area of focus is typically going to be in the valve-body area including the solenoid mechanically, as this problem should be taken on from the simplest avenue, especially if it occurs after an overhaul that included replacing the torque converter.

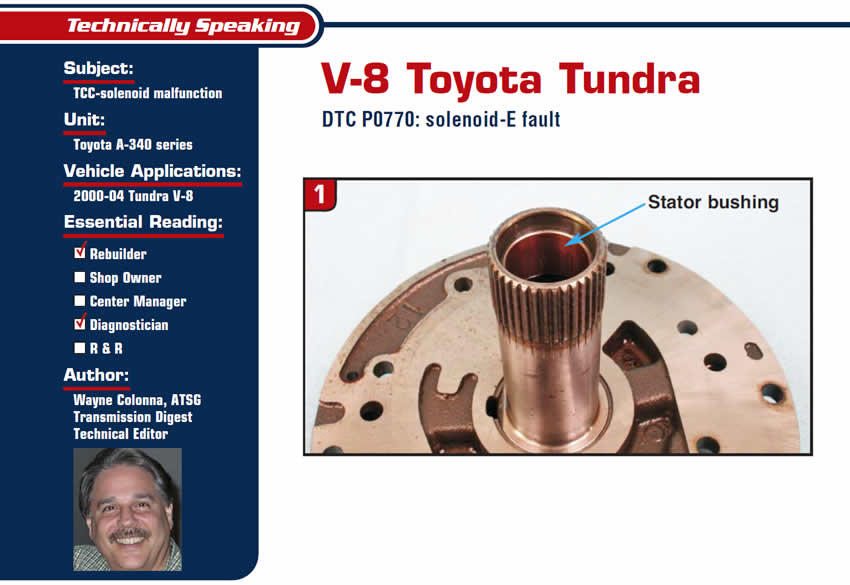

The second area of focus is a little harder to get at, especially if you just went through the transmission, and it is the front stator bushing in the pump. Getting access to it requires removal and disassembly of the pump (Figure 1).

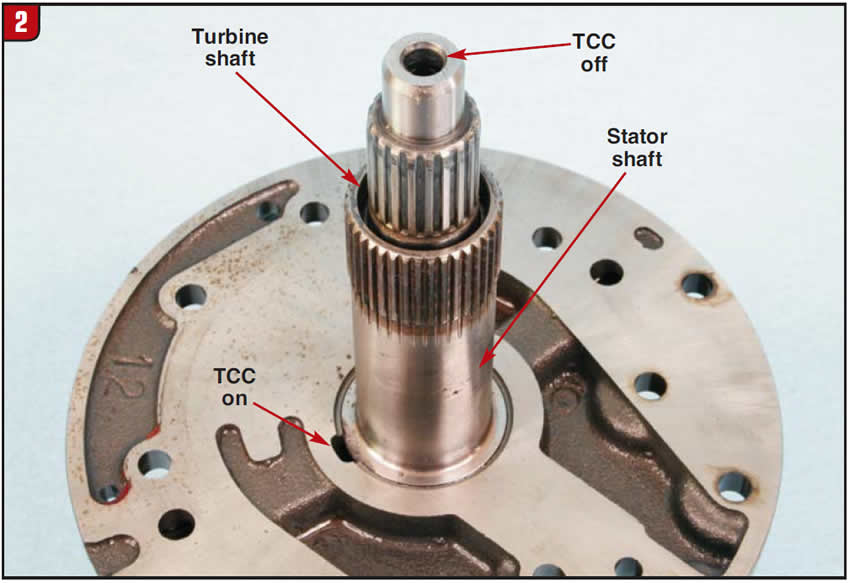

Figure 2 shows port identification of the pump; the TCC-off circuit, which is in the end of the turbine shaft; and the TCC-on circuit, which is at the base of the stator shaft. Knowing how the ports are arranged on this pump assembly, you now can see how important tight bushing clearance is. A worn bushing in this area will allow TCC-apply pressure to bleed past the turbine shaft, which in turn connects to the already-exhausting TCC-off circuit, and this also could cause the P0770 code. Clearance between the bushing and turbine shaft should be 0.003-0.005 inch, and it is a good practice to replace the bushing on an overhaul.

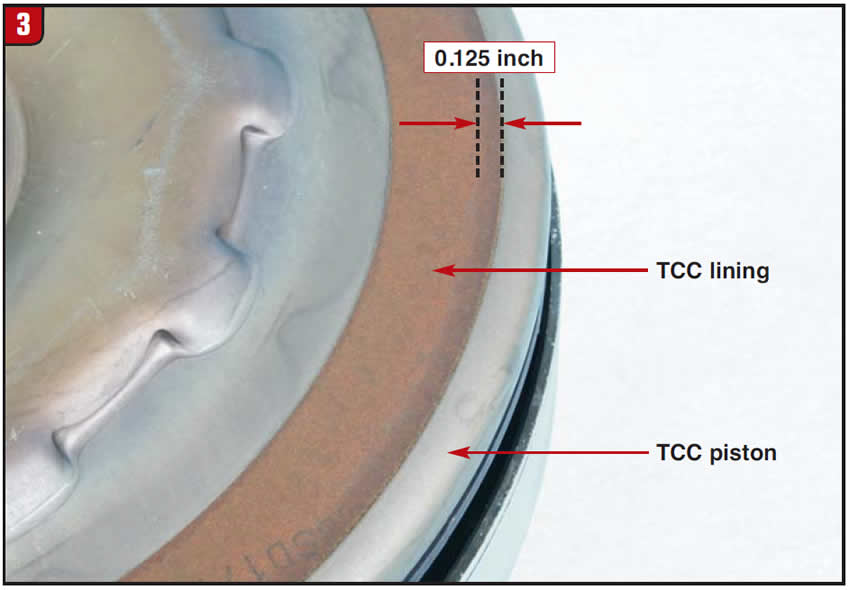

The third area of focus is the TCC, even if it has been replaced. Figure 3 shows a clutch lining on the TCC piston for a V-8 Tundra. The image illustrates a discolored area on the lining that is about 0.125 inch wide. This line is the actual contact surface that is applied to the cover of the torque converter. The reason that this contact surface is so narrow is that the piston is warped, in a clam-shell-shaped manner, by some 0.015-0.017 inch. This warping is easy to overlook. Many torque-converter remanufacturers will grind or chemically remove the old lining from the piston, and this may remove the evidence of this warping problem.

In conclusion, verify the simplest parts first, and during overhaul be sure to check or replace the front stator bushing. If everything else checks out, the problem may be a warped TCC piston that was overlooked during the clutch-bonding process. I hope this will make the areas of focus a little more plain to see – as in not the same vehicle over and over again but taillights.