Torque Converter Tech Tips

- Subject: Replacing the GM 12-inch non-lockup converter with a 298mm converter

- Unit: THM 350/400

- Essential Reading: Rebuilder

- Author: Ed Lee

The GM 12-inch 350/400 non-lockup converter is still very popular with torque-converter rebuilders. The converters are needed for many vehicles from that era that are being restored, and even more are used in the construction of street rods. The high demand and limited availability for cores have been an issue with some rebuilders. The lack of cores is easy to understand when you consider it has been more than three decades since the last GM 12-inch non-lockup converter was manufactured.

Some innovative shops have solved the core issue by retrofitting a common late-model 12-inch lockup converter: the 298mm used in the late-model GM overdrive transmissions (e.g., 2004R, 700R4 and 4L60-E). This converter can be easily adapted to the early-model, non-lockup transmissions with a few modifications. It already has a couple of common characteristics with earlier units: a 1.703-inch-diameter pilot, three-lug-bolt circle and the same input and stator spline counts.

Adjusting the overall height and eliminating the lockup clutch are the only two challenging issues in retrofitting late-model 12-inch lockup converters with the 298mm. With the help of some parts already available through the aftermarket and a small amount of machine work, these issues can be overcome.

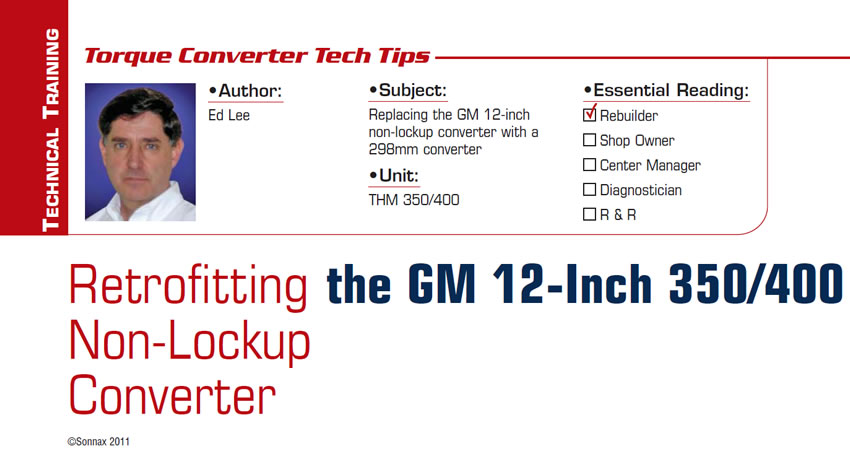

A clutch eliminator for the 298mm converter is available but is too tall (1.500 inches) in its original form (Figure 1).

Machining the clutch eliminator to a length of 0.940 inch will allow it to be used in the retrofit converter (Figure 2).

Adjusting for the differences in the overall height of the converters is a two-part process.

First, the lip of the 298mm cover where the impeller overlaps the cover needs to be shortened to make up for the space created when the clutch was removed. The OE cover measures a little more than 1.500 inches from the front of the cover to the top of the lip (Figure 3).

This measurement needs to be about 1.160 inches for the retrofit (Figure 4).

Before you take the cover from the lathe, you may want to remove a small amount of metal from the outside diameter of the cover to ensure that the impeller overlaps the cover without interference. This also would be a good time to polish the thrust surface of the cover where the clutch eliminator will ride. A 20 or finer RA on the thrust surface will increase the life of the clutch eliminator.

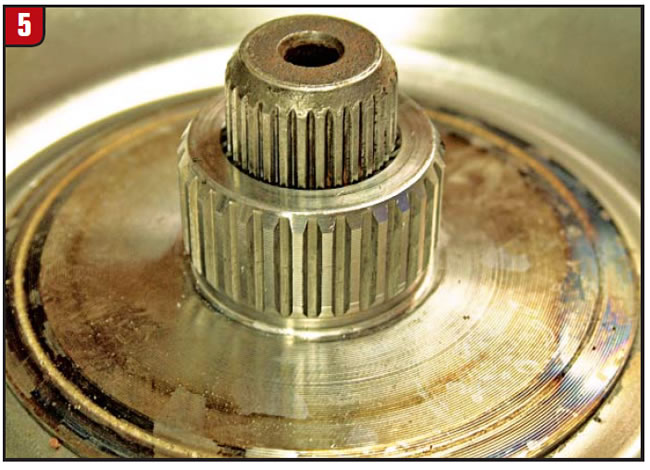

The second part of adjusting the overall height is the replacement of the impeller hub. The non-lockup converters are about 0.225 inch taller than the lockup converters in their stock form, and this dimension increases when the clutch is eliminated, so a taller hub is needed. Fortunately, there is a stock replacement hub that fits the need: the butt-style replacement hub used on the 180/Holden converters.

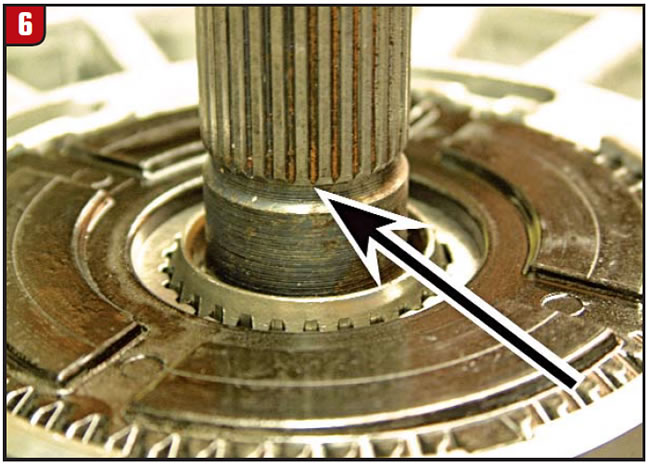

When you are checking the converter stab depth, the pump-drive slots in the impeller hub bottom on the lugs of the pump gear. If you have a keen eye for detail, you will notice in this retrofit setup that the input splines in the turbine hub bottom on the input shaft slightly before this happens (figures 5 & 6). This will make a difference when you’re checking the stab depth of the converter, but the difference is very minimal and no corrective action is necessary.

Special thanks to Frank Brunner for providing the information for this article.

Ed Lee is a Sonnax technical specialist who writes on issues of interest to torque-converter rebuilders. Sonnax supports the Torque Converter Rebuilders Association. Learn more about the group at www.tcraonline.com.