Technically Speaking

- Author: Mike Riley, Technical Editor

- Subject Matter: Torque Converter

- Unit: Toyota Flex Lock-up Converter

- Vehicle Application: Various

- Issue: Shudders

Although one of the first lock-up torque converters to be used in an automatic transmission was in a Packard Ultramatic back in the fifties, lock-ups were just not that popular. Transmissions back then either used a fluid coupling or an “open” torque converter.

Of course, all that changed in the mid-seventies thanks to OPEC and the fuel crisis. Chrysler started the ball rolling in 1978 with a real hydraulically operated on-off lock-up torque converter. Other manufacturers also jumped on the bandwagon like the Ford C5 CLC (Centrifugally Locked Converter) and the GM poppet valve (quiet release) converters, along with the start of “how many speeds are possible” race.

Beyond durability issues, the biggest complaint back then was engine bucking due to the initial lock-up speed. When an engine was fresh, the factory lock-up speed was okay in most cases;.however, a tired engine with a lot of miles just couldn’t hack it. The fix was to just raise the lock-up speed 10 – 15 mph and the problem was solved.

Another issue was lock-up quality (firmness), which could be addressed by drilling out the TCC exhaust hole or notch. Oh, the good ol’ days!

To conform to EPA regulations, fuel economy requirements and other demands, the OEMs had to start getting aggressive with lock-up strategy. That meant no more 40 or 50 mph minimal lock-up speeds, but rather, “how low can you go”. Simple on-off lock ups started to be replaced by a cushioned lock-up apply, Pulse Width Modulation (PWM) to accommodate the lower lock-up speeds. Plain-Jane on-off friction materials gave way to more advanced carbon fiber materials that could handle the additional slippage without getting fried.

In addition to the previous on-off lock-up problems, more issues started to surface with PWM designs, such as solenoid failures and valve-body bore wear due to the active nature of pulse operation. On top of bucking and chugging, converter shudder was becoming a real annoyance.

To hit increasing fuel-economy bogies, the OEMs made even more changes in the mid-nineties by adopting the EC3 (partial lock-up) strategy which could start to apply lock-up in the teens or low twenties, but with a high rate of slip. As speed would increase, lock-up piston slip would decrease, up to the point of full apply. Certain vehicles never did apply 100 percent. Other friction materials were developed to handle the continuous slip, like GM’s woven graphitic material. Different manufacturers have had various problems with the newer approaches.

Toyota has their own version of a partial lock-up converter system called flex lock-up and, no, it doesn’t function like GM or Ford. Over the years, more Toyota models have been switching to flex lock and more models have been having issues with flex lock.

Various drivability complaints have been generated due to flex lock, depending on the vehicle model and transmission as well as the various fixes that needed to be done. Beyond the direct computer strategy and torque-converter issues that may exist, flex lock can magnify problems with other areas of the vehicle, such as drive-shaft balancing or engine mounts.

Several TSBs have been issued by Toyota related to flex-lock shudder. Most of these shudder issues do no trigger trouble codes, either. 2007-and- newer Toyota Tundras with an AB60 transmission, for instance, have a TSB relating to a redesigned torque converter (figure 1). Internal converter changes were made to better accommodate flex lock. (Note: TSBs contained in this article are just the lead page. Refer to Toyota for the complete section.)

Toyota Tacoma trucks (2005-2009) with an A340 transmission may have a shudder issue that could be addressed by an ECM reprogram or replacement (figure 2). The complete TSB will provide snapshot testing procedures, if needed.

Toyota Camrys have not been left out of the mix either. Later model Camrys, like 2012 and newer models with a U760 transmission, also have had changes made to address flex-lock problems (figure 3).

Not all flex-lock issues have TSBs or trouble codes to refer to, as is the case of a 2007 Tacoma equipped with an A750E 5 speed.

Initially, a customer had his Tacoma serviced with 86,000 miles on it. Unfortunately, the shop put in the wrong fluid. The vehicle required World Standard (WS) – and that’s no joke. Always use WS where required, or shudder could rear its ugly head. The customer returned the next day with a shudder that supposedly was not there previously. The shop flushed and refilled the unit with the proper fluid, but no cigar. The problem remained and the games were on.

Overall, the transmission worked well. All upshifts and downshifts were good and on target and if the vehicle was driven with a normal or heavy throttle, lock up worked good as well. The issue was light throttle take-offs.

Flex lock on this vehicle cannot start to apply until after a shift to second gear and normally not until 20 or 30 mph, which is where the Tacoma started “buckin, chuggin, shakin and shudderin”. It would actually buck like you were shifting a manual from 1st to 4th and then it would start to shudder.

A reflash of the vehicle’s ECM was useless and the correct reset (memory reset) needed to be done with a Toyota scan system, since most regular scanners are unable to do it. There were no trouble codes and all related sensors were tested and found to be functioning correctly. An engine systems check was also performed to look for firing issues such as spark plug, coil or injector problems. None were found.

At higher speeds (above 40 mph), lock up could be cancelled with the brake pedal. If you touched the pedal, the TCC unlocked because it was in full lock up, but below 40 mph, pressing the brake pedal had no effect.

To determine if the shudder issue is definitely due to flex lock, place the shifter in manual fourth. The transmission will shift 1st through 4th and lock up will only apply in 4th and only with full apply, no partial. If all is well, flex lock is the thing you’re dealing with, as it was on the Tacoma.

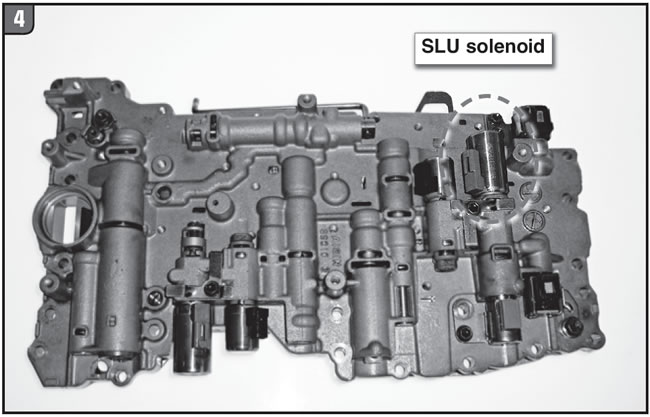

Flex-lock issues can be due to a bad converter, engine stumbles, ECM or sensor glitches or valve-body/solenoid wear problems (figure 4). The Tacoma had TCC valve wear that needed to be addressed. Fortunately, replacement valves and cutting tools are available in the aftermarket.

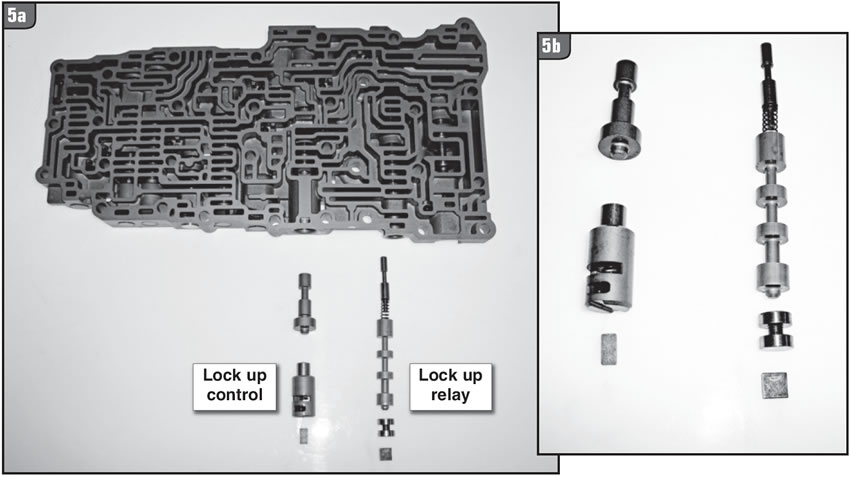

The two TCC valves of concern were the lock-up relay and lock-up control-valve trains (figure 5/5A). After the valve body was reconditioned, partial (flex) lock up worked well. Who knows what triggered the customer complaint?

In the end, it is important to know the lock-up strategy on all vehicle models. Don’t assume that they all function the same.