Shift Pointers

- Author: Jim Dial

This has now become a very frequent question on the tech line: “Hey, what are all these solenoids, and what in the world do they do?” The questions started in the 1997 model year, when the Honda Prelude came out with the M6HA transaxle. This was one of the first vehicles to receive this new-generation 4-speed. This article, I hope, will clear up some of the questions on shift strategy, clutch-pack applications and solenoid application. After all, how can you fix something if you don’t know how it works?

Which transaxles are considered new generation? M6HA, BAXA, MAXA, B7XA, MDWA, B7TA, B7YA, M7ZA, B6VA and M7WA, to name just a few. These transaxles are used in Honda Prelude, Accord, Odyssey, Isuzu Oasis, and Acura CL and TL.

Clutch-pack arrangements for these new-generation transaxles are very similar to the APX family, as in the ’90-97 Accord, which most rebuilders refer to as three-shaft transmissions. The three shafts on these earlier applications are a mainshaft that houses the 3rd- and 4th-clutch drum, a secondary shaft that houses the 1st-and 2nd-clutch drum, and a countershaft that houses the reverse selector, the low sprag and a 1st-hold clutch, which is there only to provide engine braking in manual 1st. The new-generation transaxles still have the three-shaft arrangement with one exception: On the countershaft, the low sprag and 1st-hold clutch assemblies are now gone.

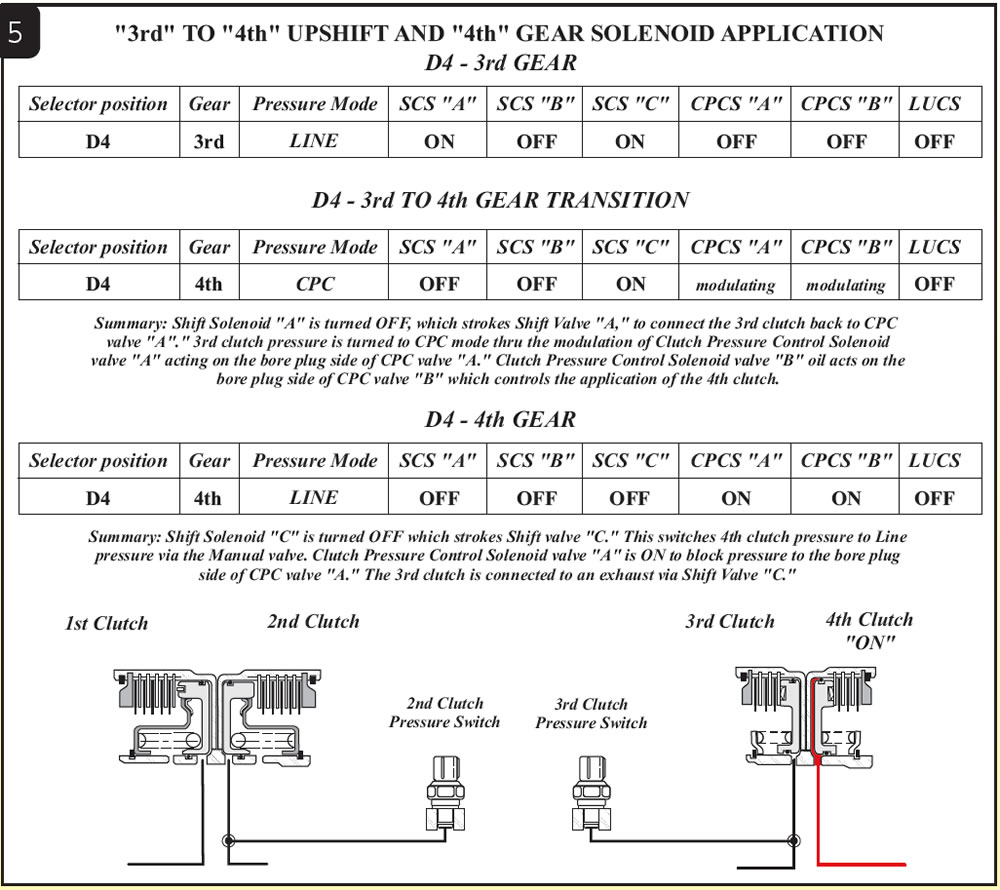

Clutch application for the new generation is slightly different, mainly because of the elimination of the low sprag. Precise shift timing is key, especially when the transmission is making a 1-2 upshift or a 2-1 downshift, because the 1st clutch must release for the shift to 2nd and then come back on for the shift back to 1st. Now, instead of the 1st clutch staying on in all forward gears, as in the APX family, now we have the 1st clutch on in 1st and the 2nd clutch on in 2nd and the 3rd clutch on in 3rd and the 4th clutch on in 4th.

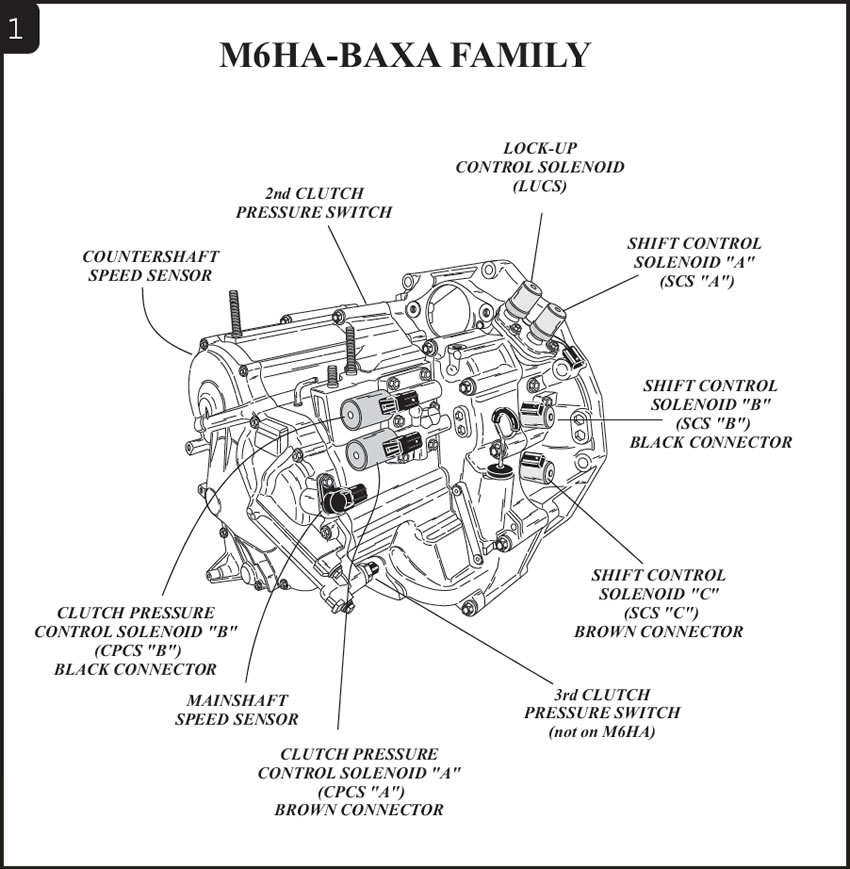

Now, back to the original question. Figure 1 illustrates an M6HA-BAXA family member with all of the solenoids, pressure switches and speed sensors that make everything happen. The first thing that most people notice is the two-solenoid assembly at the top of the bellhousing. Those familiar with the APX-family three-shaft will say those are the lockup solenoids. In fact, they will be half right. The new generation now has a lockup-control solenoid and shift-control solenoid A in the same manifold. Below those solenoids are shift-control solenoids B and C. Toward the rear of the case, a six-bolt manifold houses clutch-pressure control solenoids A and B. On the rear of the case, on opposite sides, are the mainshaft and countershaft speed sensors. Diagonally, on the bellhousing and the rear-case cover, are the 2nd- and 3rd-clutch pressure switches.

Solenoid applications, as you can imagine, are a little different from those of the APX family because of the additional solenoids, although the firing order for shift-control solenoids A and B are identical to that of the APX family. Shift-control solenoid A controls shift valve A. Shift-control solenoid B controls shift valve B and the servo-control valve. Shift-control solenoid C controls shift valve C and the reverse-clutch pressure-control valve. Clutch-pressure-control solenoid A controls clutch-pressure control valve A, input to shift valve C and the second land of the reverse-clutch pressure-control valve. Clutch-pressure-control solenoid B controls clutch-pressure control valve B, input to shift valve C and shift valve D. The lockup-control solenoid controls the lockup shift valve.

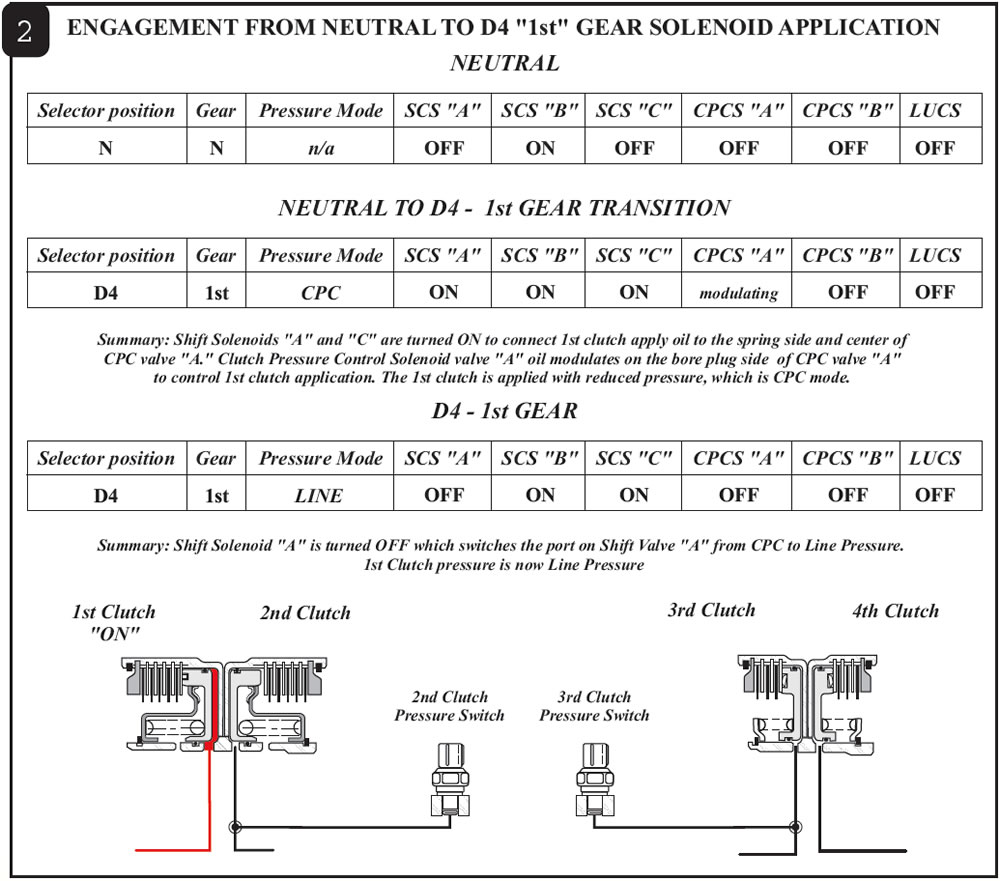

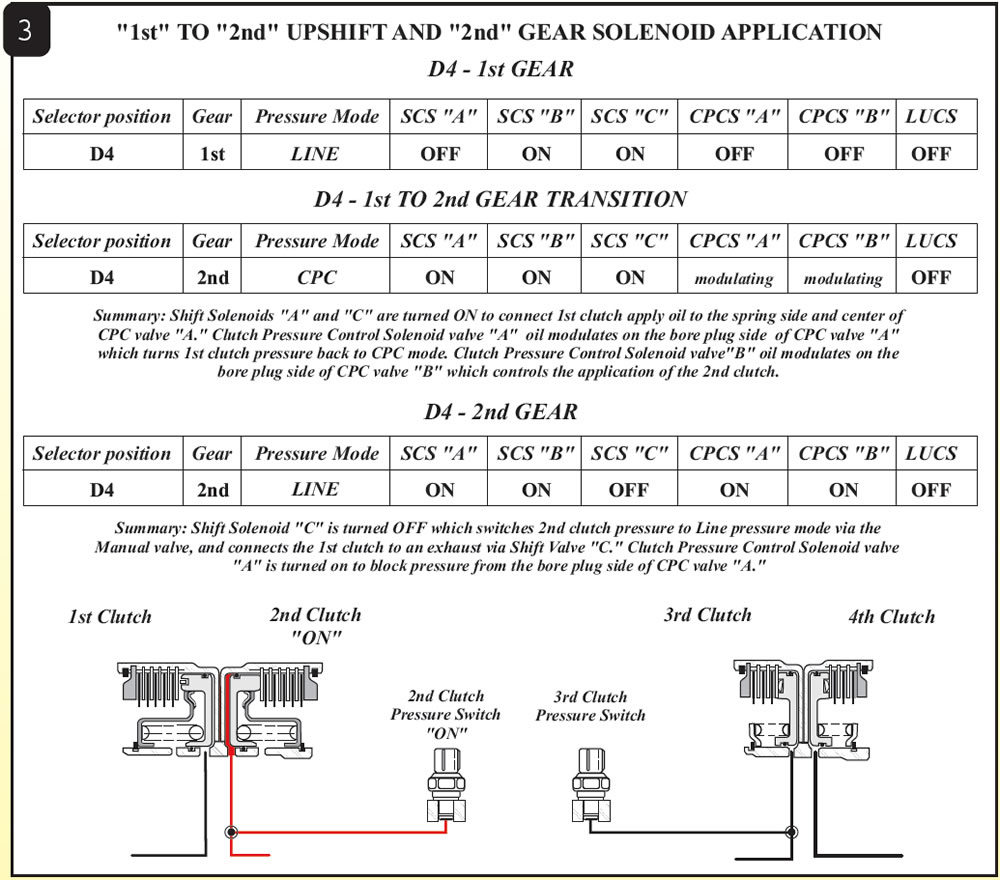

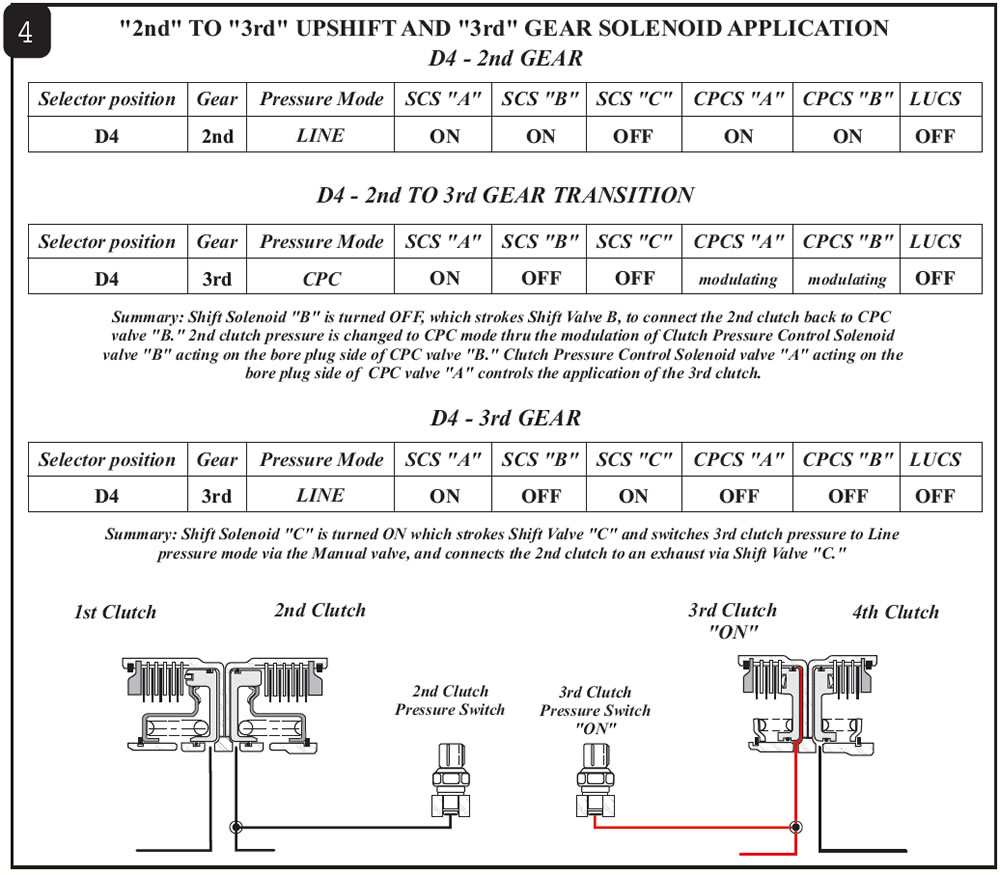

The PCM controls two different pressure modes to make sequential gear changes. The first is clutch-pressure-control (CPC) mode. This mode is used on all range applications and all gear changes. The PCM calculates the amount of CPC required by monitoring the mainshaft and countershaft speed sensors. The PCM also uses input from the 2nd-clutch pressure switch to provide a smooth transition to second gear and from the 3rd-clutch pressure switch (on models so equipped) for a smooth transition to 3rd gear. The second is line-pressure mode. After engagement of the clutch that was selected is complete, this mode holds that specific clutch on.

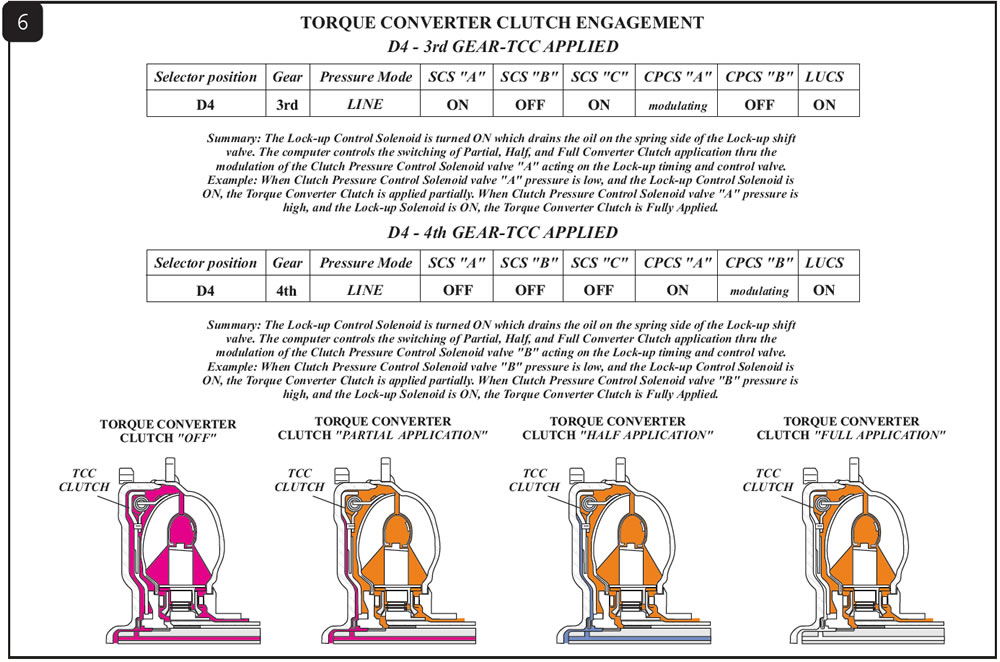

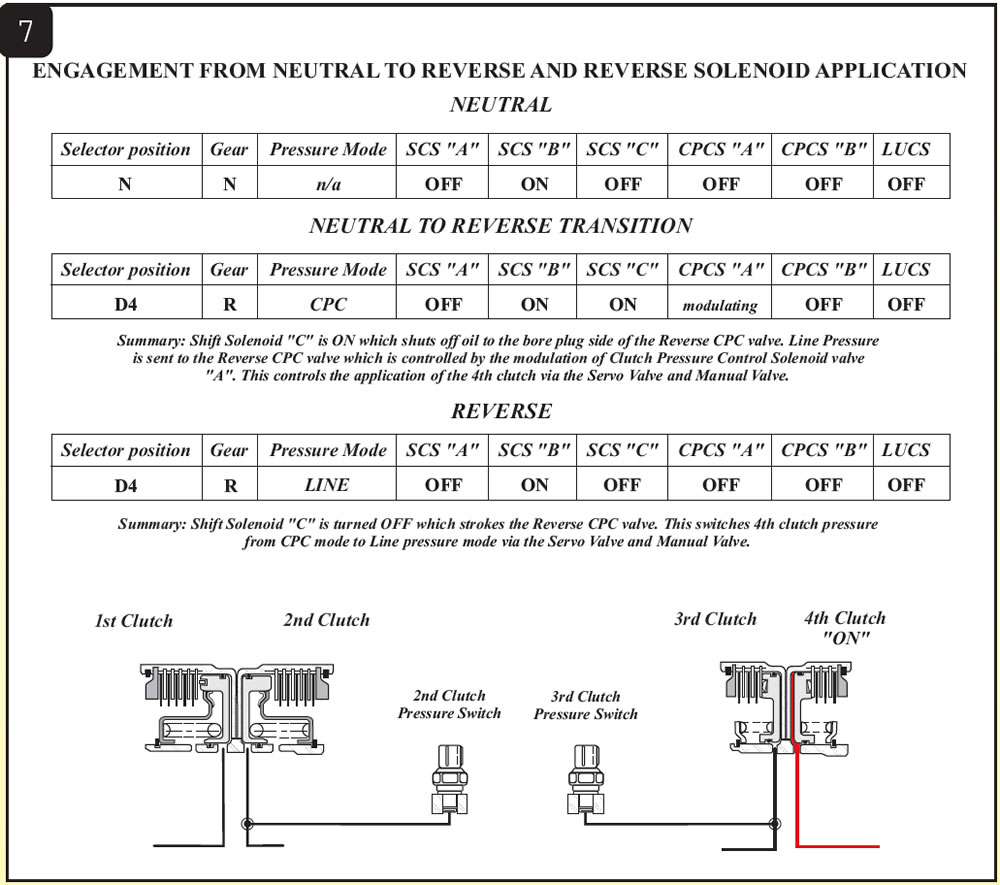

Now that we know what the solenoids and pressure-switch functions are, refer to Figure 2 to see the solenoid strategy for the engagement into the D4 position, 1st gear (refer to Figure 1 for solenoid abbreviations). Refer to Figure 3 for the 1-2 upshift, Figure 4 for the 2-3 upshift, Figure 5 for the 3-4 upshift and Figure 6 for application of the torque-converter clutch in 3rd and 4th gears. Refer to Figure 7 to see the application of the 4th clutch in reverse.

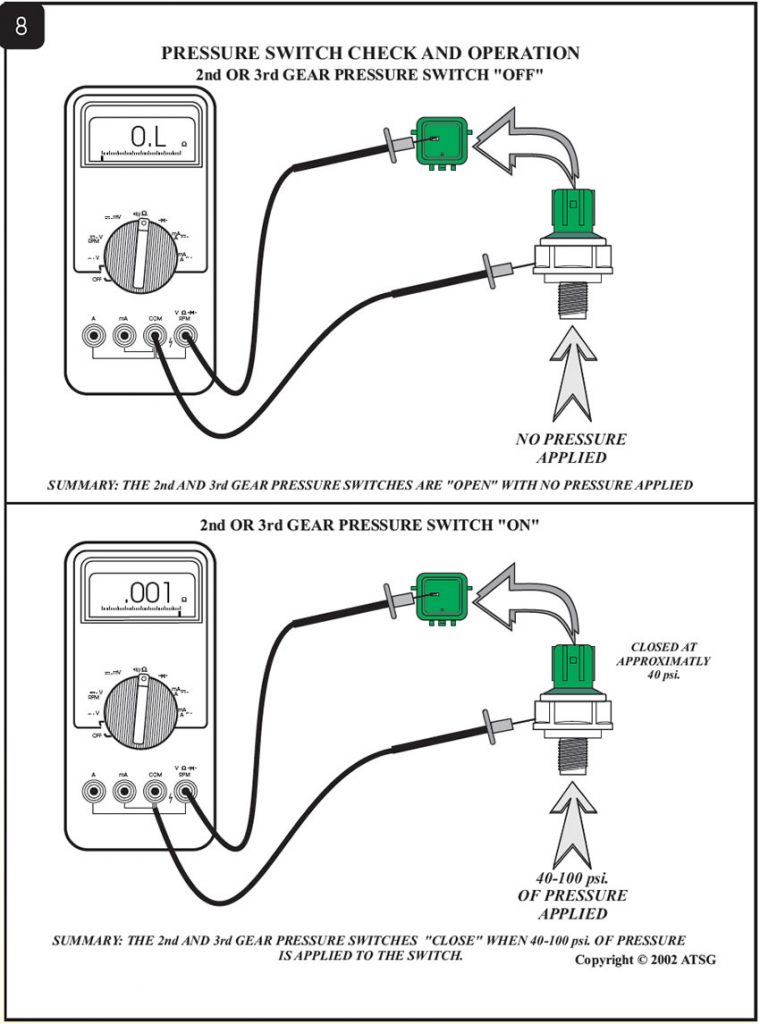

As you can see, delayed engagements and flared or harsh gear changes may result from a malfunctioning clutch-pressure-control solenoid or even a faulty 2nd- or 3rd-clutch pressure switch. Example: A long flare or slide bump on the 1-2 upshift may be caused by a faulty 2nd-clutch pressure switch. The PCM is looking at this switch to close at roughly 40 psi of oil pressure. If it does not close, the change from CPC mode to line-pressure mode will take longer, and this will cause the 1-2 up-shift to flare. Figure 8 shows how to check the 2nd- or 3rd-clutch pressure switch.

I hope this information was not too confusing or hard to follow, so that when you encounter one of these units you will have a basic understanding of how it works.

By the way, a little tip before I go: Please be aware that these transmissions will NOT shift past 2nd gear when you are testing this vehicle on the lift, because there is no load on the engine. This is normal. We cannot fix it! I can’t tell you how many times I have had calls from R&R men who ready to do bodily harm to rebuilders because they have had to pull the transmission out of the car five times – for no reason ! And do you think anyone is going to believe me when I tell them the fix was to drive the vehicle on the road instead of operating it on the rack? You’re right!

Jim Dial is ATSG senior technical consultant and a frequent contributor to Transmission Digest.