Shift Pointers

- Subject: Third-clutch failure

- Unit: Honda/Acura five-speed

- Essential Reading: Rebuilder, Diagnostician

- Author: Pete Luban, ATSG

As a rule, when I write about something it’s factual and definitive material with some kind of solution to the problem. This article contains none of those things; however, it does contain theories.

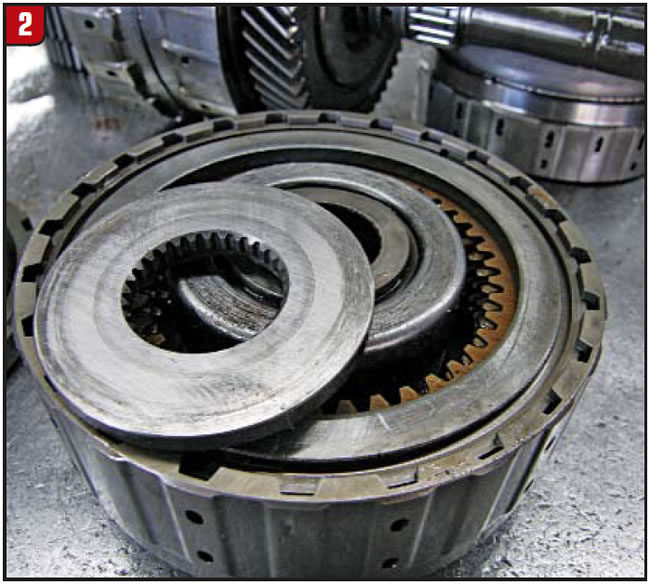

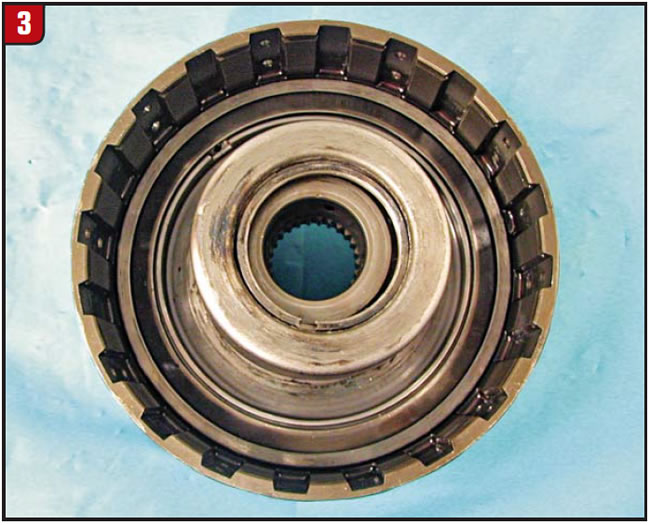

This is in reference to the common failure of the third clutch in Honda/Acura five-speed transaxles. When one of these vehicles comes into the shop with third gear slipping badly you can count on the fact the third-clutch plates will be totally destroyed (Figure 1), along with its immediate components such as the third-clutch return-spring retainer and the splined washer that sits on top of it (Figure 2) and the return-spring retainer shown in Figure 3.

A number of technicians who have experienced this type of failure seem to think that the clutch plates fail first and then the components follow because of the heat generated by the severely slipping clutch plates.

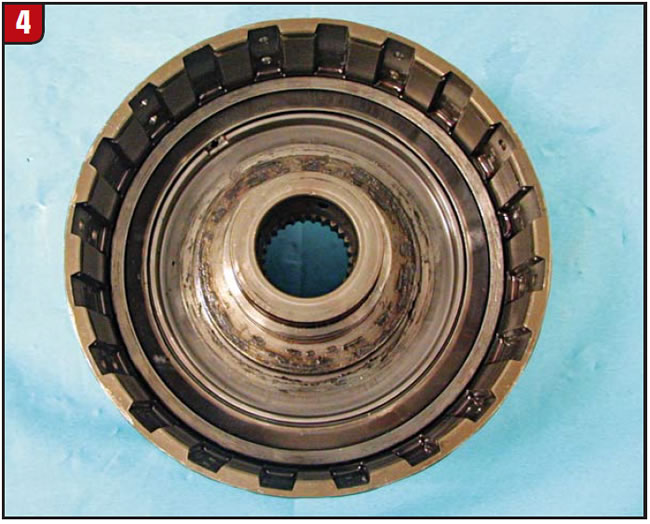

If you look at the clutch piston in Figure 4 it’s obvious from the metal deposits on the piston return spring (Figure 5) that it has been spinning around.

The return spring that came out of this drum is severely heat stressed, and it’s pretty evident where those metal deposits on top of the clutch piston came from. When comparing the damaged spring and a new spring, you can see a considerable height difference (Figure 6).

Once this spring shrinks, all the related components start spinning around, and self-destruction is imminent.

The mystery is, what is causing the third-clutch failure to begin with? Is it linear-solenoid mechanical failure, leaking CPC-valve bore plugs, leaking feed-tube bushings or a malfunctioning third-clutch pressure switch?

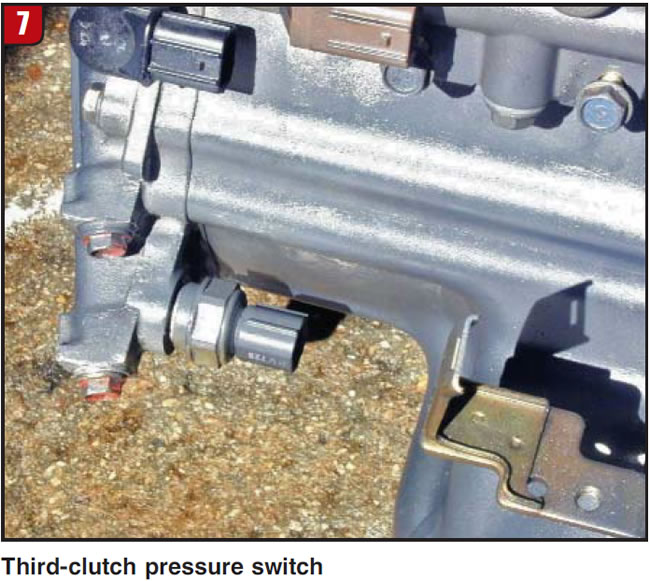

One thing I can tell you after speaking with some very experienced Honda/Acura-only technicians, the pressure switches (Figure 7) in these transaxles are crucial to proper operation. These volume rebuilders never re-use them; they can become lazy in operation and will affect the function of switching from clutch pressure during the shift and then to line pressure in gear to ensure proper clutch-pack clamping force.

Some technicians will install a different-color pressure switch from the one originally installed because that’s what they had or could get. One thing the Honda technicians agree on is, Don’t Do That!

There is a 5-psi difference between the various pressure switches, and they should not be interchanged. Five psi is enough of a difference to prevent the clutch-pressure to line-pressure switching function from operating properly, which could result in inadequate clamping force for the clutch pack.

It’s the old story: Put back what you took out! If you took out a green pressure switch, put back a green pressure switch. The beige switch is rated at 27 psi, both the black and the gray switches are rated at 33 psi and the green pressure switch is rated at 38 psi.

If anyone out there has a definitive answer to this mystery I would be glad to hear it; in the meantime the research continues.