In the transmission industry, as in life, history has a habit of repeating itself. In the case of drums cracking, history may be repeating itself a second time.

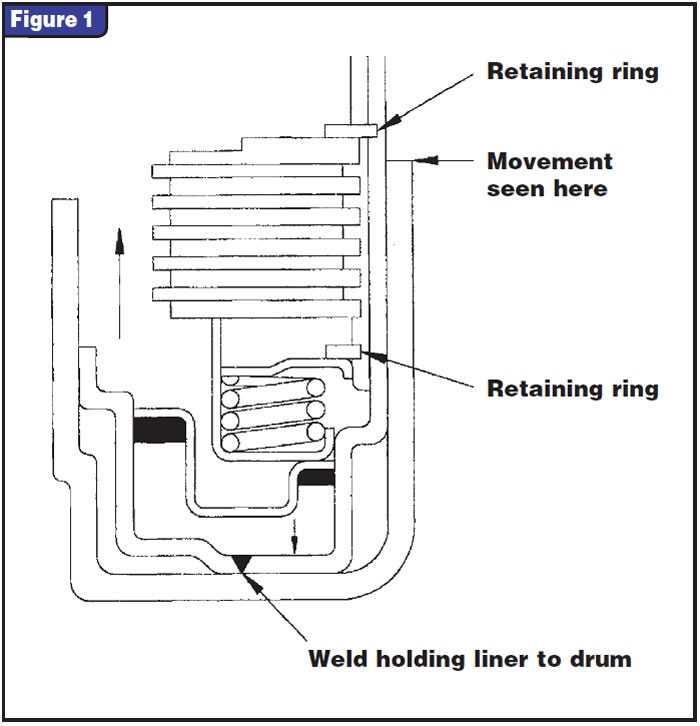

When GM introduced the stamped-steel drum for the THM 200 transmission, it presented technicians with some new challenges. The 200 direct drums would crack where the inner liner (where the piston lives) was joined to the outer shell. The weld that holds the two members of the drum together is subject to pivotal flexing each time the clutch is applied. Over time, this flexing action will cause a crack at the weld.

The challenge to the technicians was in finding the crack (leak). Since the crack was under the piston and not visible from the outside of the drum, it wasn’t detectable with a normal air check. Some ingenious technicians learned that adding a small amount of mineral spirits between the mating parts of the drum before the air check helped to find the crack. A mist would rise from the cavity between the mating parts at the point of the crack when air was applied.

In the April 1997 edition of Transmission Digest, technicians were warned that the same problems that had plagued the THM 200 direct drums for years were now occurring on the 440-T4 and 4T60-E intermediate drums.

The article also offered a solution to prevent future cracking on the intermediate drums.

Today’s technicians are faced with the same problem on the 4L60 and 4L60-E reverse drums. The cracks are equally as difficult to detect, but the nice part is that the same methods for finding the cracks still work today.

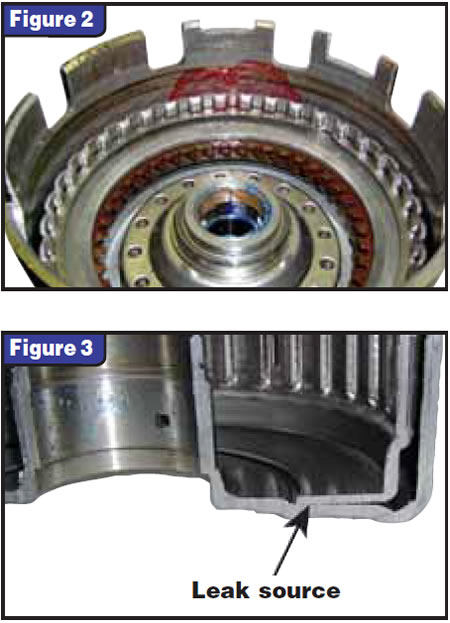

Figure 2 shows a drum being air-checked after a small amount of ATF was added between the inner and outer shells. Although the leak was very visible after the ATF was added, it was previously impossible to see. The only clue that the drum was defective was the burned clutches the technicians found during the initial teardown.

After the technician had eliminated all the other possible causes for the burned clutches, he turned his focus to the drum. The technician’s diligence paid off when he repeated the air check with the added ATF. After the second air check proved that the drum was leaking, the drum was cut in half at the point of the leak (see Figure 3).

It was now easy to see that the inner liner was separated from the outer shell at the weld. We now know why hindsight has 20-20 vision.

Special thanks to Jason Woodall, warranty-analysis technician, and Sean Byrd, quality/production manager, both of Jasper Engines & Transmissions, for their help in solving this problem.

Ed Lee is a Sonnax technical specialist and a member of the TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians. ©2007 Sonnax Industries Inc.