R&R Tech

- Subject: Transmission overheats during stop-and-go driving

- Unit: 5HP24

- Vehicle Application: 2001 BMW 740i

- Essential Reading: Rebuilder, Diagnostician, R & R

- Authors: Jody Carnahan and Dave Wilkes

We were in Las Vegas recently attending the fall shows, and as happens in this industry you always meet up with other technicians and shop owners wanting to talk shop. On this occasion I had the pleasure of meeting Dave Wilkes of Dave Wilkes Transmissions. We started talking shop (when we were actually supposed to be relaxing at a cocktail reception), but you know that’s never going to happen when someone brings up a problem with a vehicle that they recently had in the shop. Like all technicians, I wanted to listen.

In this particular situation, Dave had been working on a 2001 BMW 740i with a 5HP24 transmission. The vehicle originally came in with a complaint of leaking from the front. The unit was very low on fluid, was slipping and the fluid was burnt. The shop recommended that the transmission be overhauled because of the conditions mentioned and the mileage on the unit. Everything went normally with the rebuild, and the customer left with a properly working unit.

Three months and 4,000 miles later, the customer returned with a complaint that under stop-and-go conditions the transmission would sometimes clunk and would downshift on its own for no apparent reason. After 20-30 minutes of driving under the same stop-and-go conditions, the transmission would start shifting late through the gears. There was also oil on the back of the vehicle and it was smoking. On the initial inspection and road test the transmission appeared to perform normally, but the technician noticed that the fluid level was about a quart low. After scanning the vehicle, he found it had codes 049 (symptom gear check) and 034 (transmission sump oil temp high).

The codes were cleared and the vehicle was road-tested again. The transmission would operate normally with the fluid temperature around 100°C (212°F), but the 049 gear-check code would return and the transmission would also go into failsafe. Knowing that the vehicle owner typically drove in stop-and-go traffic, the technician decided that he needed to drive the vehicle under the same conditions.

After the vehicle was driven under these conditions, the transmission temperature reached 130°C (269°F) and the computer appeared to put the transmission into a high-temp shift-mode strategy. The transmission would take off in first and have late shift commands into second and third. Once the transmission fluid cooled to 120°C (248°F) the transmission would operate normally. It also operated normally with the vehicle being driven on the highway at steady speeds with a fluid temperature of around 100°C (212°F). One other note: The converter-clutch engagement appeared to be normal regardless of the driving conditions.

With the vehicle back at the shop, an inspection on the rack revealed a transmission leak from the front-pump area. This would require removing the unit from the vehicle.

When the transmission and torque converter were inspected, no internal problems were found. The valve body and solenoids were replaced on the basis of the 049 code.

With the transmission reinstalled, it was time for another road test. The transmission operated normally and no codes returned. It was now time to do some more stop-and-go driving.

After 20-25 takeoffs and stops, the transmission temperature went from 100°C (212°F) up to 130°C (269°F) and – you guessed it – the unit went back to the same high-temp shift strategy. It was now time to dig a little deeper.

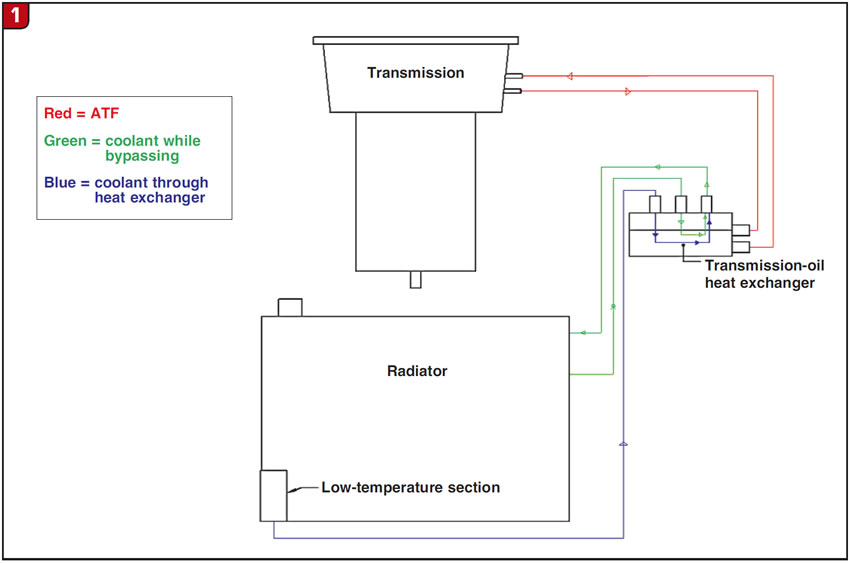

After removing the transmission, the shop performed a thorough flushing of the cooler system. This car has a unique system that incorporates a transmission-fluid heat exchanger (cooled by the radiator) through a series of hoses and a thermo checkvalve.

Here is a brief overview of how the system works. The radiator has two sections and is a cross-flow design. The upper 4/5ths of the radiator is used for hot engine coolant, and the lower 1/5th is a low-temperature residual-coolant-storage area. This is used to cool the heat exchanger (see illustration). The system also uses an integral thermostatically controlled valve that sits on top of the heat exchanger. When the transmission fluid is cold, coolant is guided from the engine (water-cooled housing) to the heat exchanger. This part of the system is actually used to warm the transmission fluid through the heat exchanger.

As the transmission fluid rises to operating temperature the engine-coolant temperature also rises. This causes the wax core in the integral thermo-controlled valve to expand. The expansion pushes on the regulation valve and closes the warm-coolant port while it opens the low-temperature-coolant port from the residual 1/5th storage area of the radiator. Thus the 1/5th section of the radiator sends coolant to the heat exchanger for cooling.

Now that we had a little better understanding of how the cooling system works, it was time to figure out why the transmission was getting this hot.

As previously mentioned, the transmission performed well and had good torque-converter-clutch application. We did not suspect it was causing the overheating condition. A cooler-flow check found that it was flowing four quarts in 20 seconds. It was decided that the most-probable cause would be the heat exchanger and/or the thermo valve.

With the new heat exchanger and thermo valve installed, it was time for another road test, and to our surprise this made no difference in the transmission operating temperature. The new exchanger had a cooler-flow rate of two quarts in 20 seconds, which was more than adequate cooler flow. Now what?

There was only one component left in the system that could be the culprit. The shop ordered a new radiator, and after it was installed there was a significant difference in the overall operating temperature. Under normal driving conditions the transmission temperature was around 90°C (194°F), and under repeated stop-and-go conditions the temperature never got over 106°C (223°F).

We now had a successful repair. But why was the radiator causing the problem? As mentioned previously, it is the lower 1/5th of the radiator that is used to cool the heat exchanger. When the tank was removed from the old radiator the lower 1/5th was plugged with debris. When the coolant was diverted from the 4/5th section to the lower 1/5th low-coolant-temperature section there was not adequate coolant getting to the heat exchanger.

Jody Carnahan, who has been with Certified Transmission for 25 years, is a warranty and technical director and also has been a builder and a department and store manager. Dave Wilkes is the president of Dave Wilkes Transmissions, Ventura, Calif.