Up to Standards

- Subject: Catastrophic driveline failure

- Unit: Tremec T56 Magnum

- Vehicle Application: 2010 Camaro race and display car

- Essential Reading: Rebuilder, Shop Owner, Diagnostician, R & R

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor

Every technician who rebuilds transmissions has failures, which we call comebacks. We get the failed or improperly working unit back, diagnose the cause and make it right.

The entire exercise we go through on a daily basis making repairs is based on the same set of facts: We have to first diagnose the problem, understand the cause of the failure, correct that cause and then certify that the unit is working correctly and deliver the product.

Rebuilding is not replacing parts that are broken or worn but is a concentrated effort to correct the design defects that are inherent in all manmade products, so that all the new parts we are installing will not fail again. The defects can be internal to the unit we are working on or external in other parts of the vehicle, such as computer control or electronic issues, which if uncorrected will put us back to square one.

Any technician who understands the power flow and method of operation of the unit is by nature an accomplished detective. This is not the pursuit of lawbreakers but a need to do a root-cause failure analysis on every unit you work on. The following case study illustrates how important it is to thoroughly analyze the causes of transmission failure on every unit you work on and to be sure to verify everything you have done on the repair whether it succeeds or results in a comeback.

We remanufacture manual transmissions, transfer cases and differentials and sell them to the repair industry wholesale. Our company also has a performance and racing division that provides remanufactured and new units to professional and amateur race teams worldwide and to the automotive enthusiast who wants to upgrade the factory unit he has for better performance.

Most of our attention is on the six-speed units manufactured by Tremec. The factory unit is an excellent design for the Corvette, Camaro, Firebird, Viper, Challenger, GTO, Mustang, Cadillac CTS-V etc. originally equipped for street use. However, when you are dealing with the performance market, where people are operating with much-increased horsepower and torque demands from the engine, you always end up reengineering the design to accept the punishment it will take.

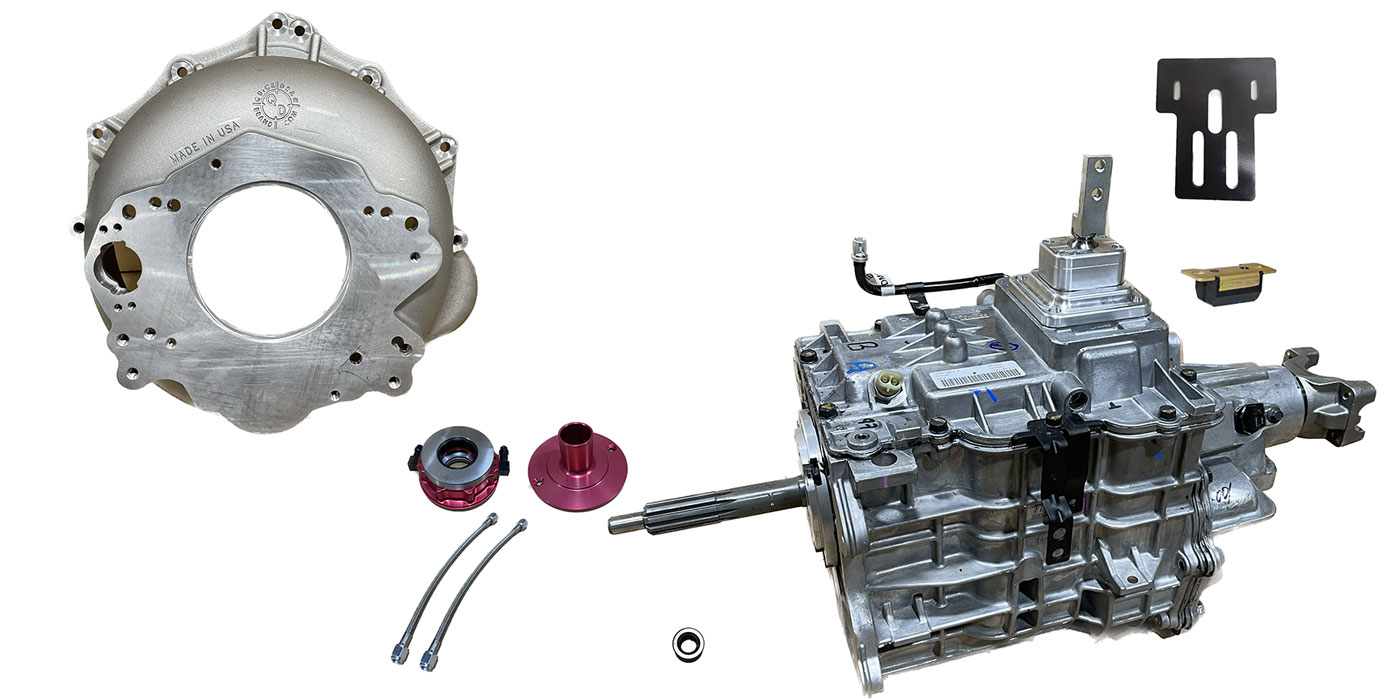

To that end we manufacture our own brand of six-speed transmissions based on the Tremec T56, TR6060 or T56 Magnum design. The brand name is Tranzilla, and within that brand we have several levels of units that are all based on the T56 and T56 Magnum design, modified for higher horsepower and torque and designed to live in the racing/performance environment.

The premium model is the Tranzilla designed to handle up to 1,200 horsepower and 1,000 lb.-ft. of torque. These gears and shafts use 9310 alloy, and the entire gear set is redesigned to live in races like the 24 Hours of Daytona, with continual shifting at up to 8,000 rpm for prolonged periods of three to 24 hours.

The next level of unit, again based on the Tremec T56 and T56 Magnum design, will handle 850 lb.-ft. of torque for street and track, with the same engine-speed levels possible. These units will be found behind engines with turbos, superchargers, nitrous-oxide systems, big-blocks instead of small-blocks etc. that boost demand on the transmission over stock. A huge number of hot rods and early muscle cars out there are being converted to six-speeds to offer the user a double overdrive for better mileage and more-enjoyable cruising on the highway.

The big issue on the racing side is reliability and durability. The unit has work for the purpose desired, and it has to last for the duration of the race under really high-speed abuse and sometimes driver punishment. Nobody warrants a race transmission, but it has to get the job done or the team will quickly move to another supplier. The cost of each race is very high when you consider entry fees; fuel; tires; transportation for the car and the whole crew; meals; lodging; and the return on investment to the sponsor. Teams on the professional level such as the NASCAR-owned Grand American Rolex series or the Speed World Challenge series can spend 30 to 50 grand on each event. If they don’t finish the race because of your product failing, the phones will light up immediately, and no one wants to disappoint a customer or their sponsors.

Our designs have been tested in thousands of laps at road and drag races around the world and proved to work. There will be failures, but usually they are driver error or results of contact with immovable items such as walls. We do very careful root-cause failure analysis on every unit to determine why it failed. Most of these units will get returned to be freshened up after every race or every second or third race during the season. You are only as good as the last thing you did for anybody.

Now to the failure from hell. We were contracted to build a T56 Magnum Tranzilla for a custom-built 2010 Camaro to be used in racing and product display. The car was equipped with an LS7 supercharged engine, Ram dual-disc clutch, custom-built 12-bolt aluminum independent rear-axle assembly, modified suspension, heavy-duty CV joints and shafts, and a chrome-moly driveshaft custom built by one of the premier driveshaft shops in the nation. The car had a torque output of 850 lb.-ft. and produced close to 600 horsepower at the rear wheels. The rear was supported by custom-fabricated brackets, and the design looked excellent.

Shortly after installation the car was road-tested and the driver felt a vibration at speed. During a series of subsequent downshifts, the driver said, the driveline exploded. The bottom-line result was a $70,000 insurance claim. We got all kinds of phone calls and had a number of questions from the insurance adjusters.

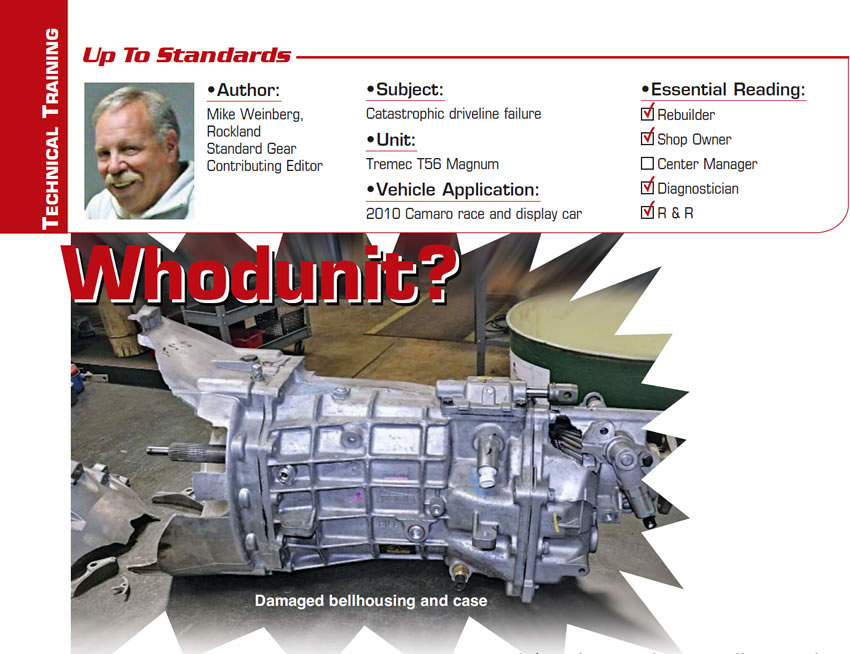

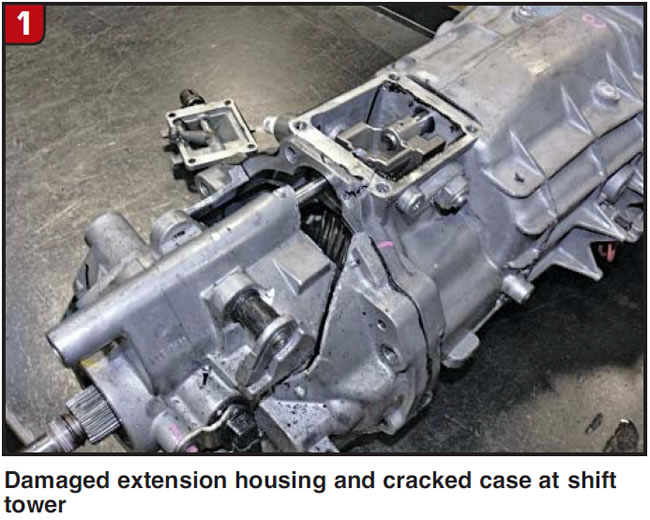

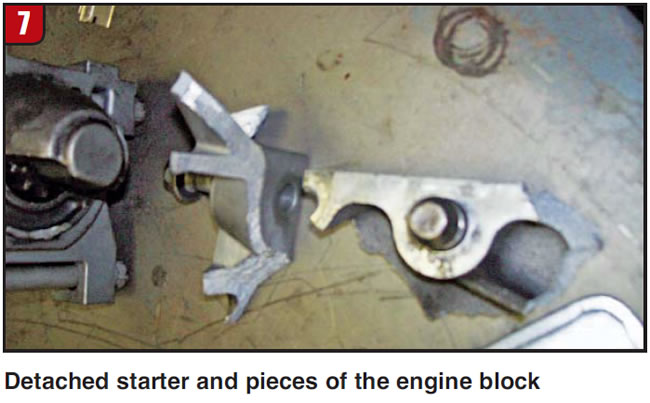

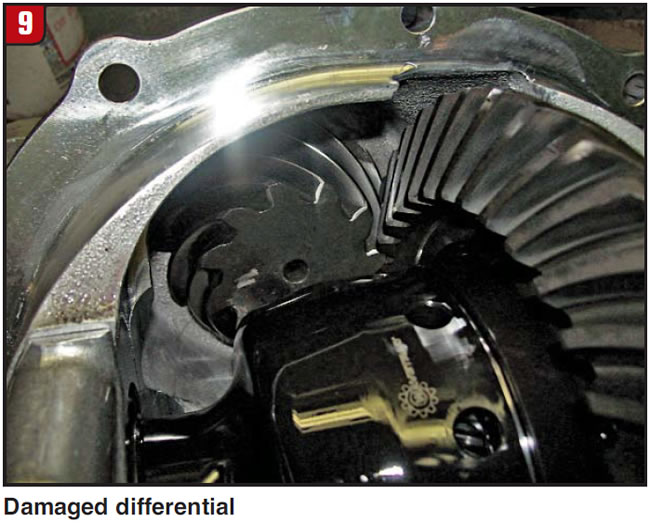

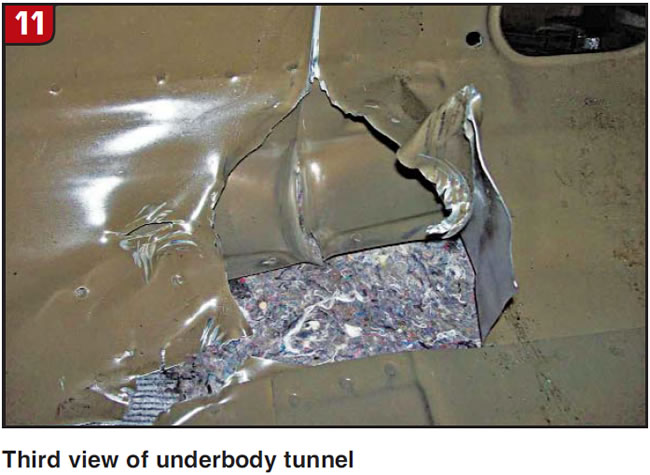

The damage was incredible. The transmission bellhousing was torn off the block, and this in turn tore the starter off the block, destroying a very expensive engine. The transmission was cracked in half at the extension housing and had another crack near the shifter attachment points, the cross member was destroyed, the driveshaft was in three pieces, the yoke was broken out of the differential and the rear housing was damaged. As the transmission moved off the block it struck the sheet metal in the tunnel, tearing out a piece the size of a basketball, ruining the tub and probably tweaking the frame.

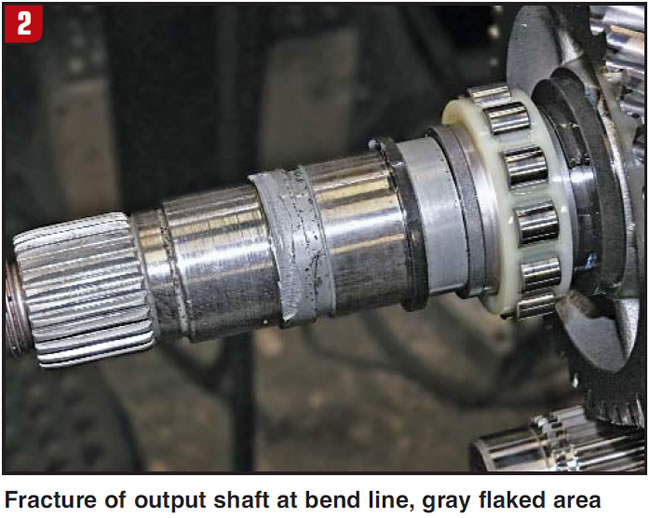

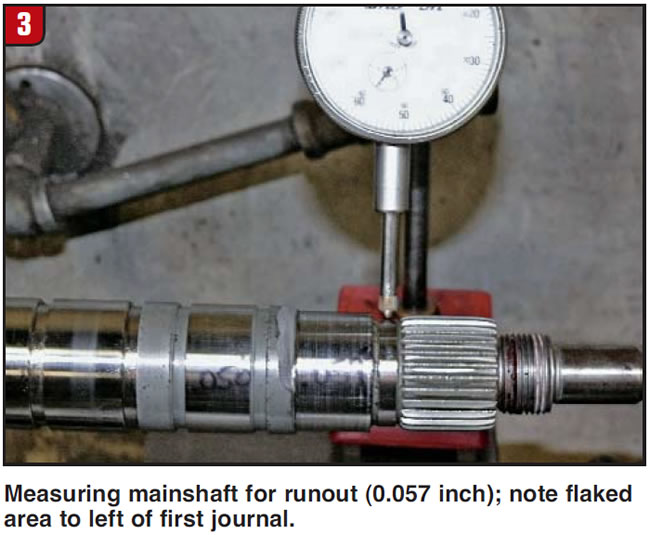

We asked for the transmission to be returned to us for inspection, and now we had a real whodunit on our hands. The trans came back and was inspected and photographed. Although the cases were destroyed the internal gear train suffered no damage. The mainshaft was bent, and measuring runout on a good lathe we determined it was out in places by more than 0.050 inch, with the start of a fracture showing up at the bend line. This was a terrific relief, as it proved to us the trans was not the cause of the failure but a result.

Now was the time to make a real crime-scene investigation to put a cause to the failure. We made many phone calls to all the people involved in the build. In one of the photographs we saw that the straps retaining the U-joints were spread. This concentrated our effort in that area, as a loose U-joint could definitely light the fuse on this deal. It was determined that the bolts were all torqued to the correct specs and had retained their position – another result, not a cause.

Moving along, we spoke with each individual involved in the steps between the installation and the road test. One of the team members had taken the vehicle for a four-wheel alignment. He remembered having difficulty getting the car onto the alignment rack. This was a breakthrough clue. He said that when he was driving it onto the alignment rack the car would not move and “I had to gun the hell out of it to get it up on the rack.” He had the same issue coming off the rack. Now we had the beginning of the answer.

We went back to the driveshaft and examined it carefully, and there was the answer. We called the alignment shop and asked them, “Did you use the blue alignment rack when you did it?”

The reply was, “How do you know what color the rack is?”

The driveshaft looked like a barber pole with a blue stripe corkscrewing around its length. Because of the Camaro’s ride height, as the driver went up on the rack the driveshaft bottomed out on the cross bar of the rack, stalling the car. Instead of getting out to look the driver just added power, forcing the car onto the rack and making the driveshaft look like a Twizzler. The driveshaft was now way out of line – made worse by the chrome-moly material, which although stronger will not handle any bend or distortion. During the road test the driveshaft went into a major whip and distortion because of the increased speed and destroyed the transmission, engine, differential and driveline tunnel.

We got lucky in being able to put a cause to the failure and not being the donkey everyone could pin the tail on. The customer got paid from the insurance provider and ordered another unit from us as the car is being rebuilt. The guy who drove it onto the alignment rack and caused the problem is now probably a fugitive. The pictures here illustrate the damage sequence.

There are lessons to be learned from the story. Uneducated people make big mistakes. Luckily, no one was hurt and the damage can be fixed. What you can take away from this is applicable to everyone who works on cars. Little details can create big disasters. We work on product every day that can put someone’s life in danger, whether it is on the highway or just setting a car up on the lift properly.

Take nothing for granted, and pay attention to detail. When you have a failure, keep emotion out of the equation and let your intellect work out a thorough examination to discover the root cause. If you own the mistake, make it right and learn from it. If you didn’t create the issue, do what you can to help fix the problem; fixing the blame never cured anything.