Up to Standards

- Subject: Using the correct lubricant in transmissions, differentials and transfer cases

- Units: Tremec T56, BW 4473

- Essential Reading: Rebuilder, Diagnostician

- Author: Mike Weinberg, Rockland Standard Gear Contributing Editor

The squeaky wheel does not always get the grease

The massive, never-ending change in automotive technology has been making our daily routines more complicated. This has been going on for many years and will never stop. If you don’t spend at least a couple of hours a day reading up on the new units and various fixes, you will rapidly be left behind.

One of the things often neglected is lubrication of the transmission, transfer case and differential. As with the automatic transmissions there are now dozens of specified lubricants that a professional shop must have available. What used to work no longer does, and putting the wrong lube into a late-model unit will result in spoiling a good rebuild. You must use the correct fluid for the unit you are working on. It sounds logical, but if you understand why, it will go a long way toward preventing shift complaints and outright failure under warranty due to incorrect lube fill.

In the past most manual transmissions used brass or bronze synchronizer rings for smooth, clash-free shifting. Those materials are still in use, but new technology has been developed using synchro rings that are paper lined, carbon fiber and sintered metal. For the ring to work correctly, it must be matched to a specific fluid fill.

At one time transfer cases were simply mechanical power dividers that were manually shifted. We now have a variety of transfer cases that are “intelligent,” active, electronically controlled units that can operate without driver input. Many of these units are operated by an internal clutch pack, similar to those found in automatic transmissions. Just as in automatics, these clutches will slip or generate a lot of heat and chatter if the unit is not filled with the correct fluid.

The differentials in most vehicles also have changed in their manufacture and design. There are now rear ends equipped with locking carriers that can use clutches, viscous couplings or gear-driven differentials to limit wheel slip in various driving conditions. Again, the correct fluid here is critical to proper operation and long life.

There are different advances in gear technology in manufacture that have come into the market. There is the five-cut manufacturing process that has been around for a long time in the production of ring-and-pinion sets. Now we are seeing the two-cut Phoenix design, which results in different setups when a rear is being built. The five-cut process usually demands a backlash adjustment of 0.008-0.010 inch; the two-cut should be set to 0.004-0.006 inch for proper operation.

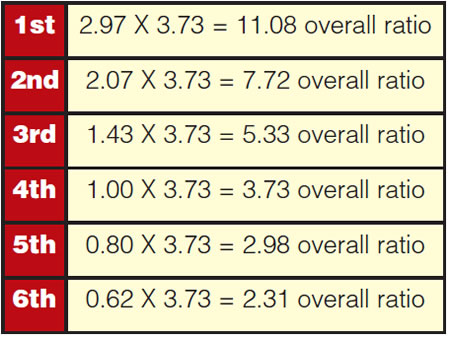

The different materials used in the limited-slip differentials demand a specific additive to have the correct coefficient of friction for the clutch to grab and release without slippage or chatter. You will find carbon fiber and sintered metal in many of these applications, and they all require the correct fluids. Typically a rear end will generate the most pressure in the gear train, as the overall ratios of the transmission and differential are very high in the lower gears. Overall ratio for each gear is achieved by multiplying the specific gear by the rear-end ratio. The accompanying chart will show you the overall ratio generated by a typical Corvette Z06 with a 3.73 rear-end gearing.

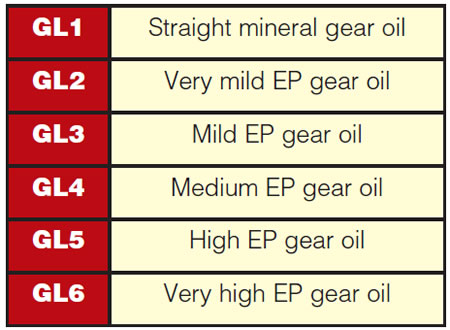

It is easy to see from the numbers that there is a lot of pressure on the gears in mesh in the differential in the lower gears and that the pressure of the gears meshing together declines in the higher gears. Rear-end lubricants contain EP (extreme-pressure) additives to lessen the impact on the gear train. The American Petroleum Institute (API) has designated six classifications of gear lubes that are based on the amount of extreme-pressure additives in the oil.

Again, using the correct lube in the unit you are working on is the difference between success and comebacks.

For some reason there is a great mystique about lube oils. Perhaps it is not properly explained in the manuals, or the massive amount of advertising hype done by the lube producers adds to the confusion. Oil is oil; the devil is in the details of what is added to the oils to make them suitable for use in a specific application. Although the viscosity (essentially thickness) of the oil varies by application, it is the additive package in the oil that creates suitable performance for the intended use. You hear a lot about synthetic oils. What is the difference between synthetic and natural oil? Again, oil is oil; it all comes out of the ground.

When crude oil goes from the well to the refiner, it is catalytically “cracked,” a process of heat and chemical reaction that separates the various components into usable form. Toluene, benzene, kerosene, gasoline and many other compounds are separated and sold off. The remaining petroleum then is made into lubricants of various types.

Forgive me for making a very complex process sound so simple, but for the purposes we need it will do. How the oil is cracked creates basic oil or synthetic oils. The difference in the synthetic process is that this form does not occur naturally. The cracking process for the synthetic versions rearranges the molecular chains in the oil into longer, stronger bonds. Now the refinery adds a package of compounds to the oil to make it work for a specific use. Friction modifiers, stabilizing agents, EP additives, cling-enhancing agents, detergents and anti-foaming agents are added at this point to create a product that will work correctly for the intended use.

What makes synthetic oils worth the extra cost to you is the fact that the longer, stronger molecular chains will tolerate more heat before the additive package breaks down. The oil will always survive, as we can see by recycling our waste oil. The additives are dead or badly damaged through heat and contamination, but the oil can be purified and reused, with a new group of additives added.

Manual transmissions, for the most part, are “splash lubricated.” There are a few models, such as the Tremec late-model T56 line, that have internal oil pumps driven off the counter gear for pressurized lube. ZF has units that contain the same setup, but most units are simply lubricated by the gears splashing the oil around inside the transmission case.

In many designs there will be shields, troughs, scoops or other devices internal to the transmission to direct this oil to the parts not easily reached by the splashing lube. An instant recipe for disaster is to leave these items out during repairs.

If the gear splash is lubricating the unit, it is easy to see how failures occur because of towing or low oil levels. I am sure you have all seen the mess created by a tow-truck driver who tows a front-wheel-drive automatic with the front wheels on the ground. The pump is not providing pressurized lube, and by the time you see the planetaries they are melted. When a stick vehicle is being towed, the transmission is in neutral and the driveshaft is turning through the rear wheels. The driveshaft will turn the mainshaft, but the counter gear and input gear are stationary. How much splash does this generate for the lube? In low-oil conditions, transmission operating temperatures rise dramatically, additive packages die, and hard-to-reach places like the pilot bearing on the nose of the mainshaft in the input bearing go to the great junkyard in the sky.

Drivetrain lubricant levels are always a problem for the vehicle owner to check. Rarely are there dipsticks to check the levels, and most owners are lax on preventive maintenance and complain only when things are past the point of no return. The correct fluid level is a must for long life. Encourage your customers to come in for routine lube changes. It adds to your bottom line and protects the unit with fresh new lube that has the additive package intact.

Overfilling is just as bad as underfilling. Overfilled units will puke some oil out the vent, but you will have windage and overheating issues. Windage is the increased effort that rotating parts require to run through the extra oil. In the racing world, they run what is known as dry-sump motors. There is little or no oil in the engine oil pan. As the oil returns to the pan it is sucked out by a scavenge pump and returned to the lubrication inflow. This boosts horsepower and torque considerably, as the crankshaft never has to run through oil. Try running on the tide line at the beach, and then try running two feet into the water. Moving the water will triple your effort to make forward progress.

Another side effect of windage from too much oil is a change in gear synchronization and hard or notchy shifting. When you dip the clutch to shift, the excess oil slows the gear train faster and changes the timing of the synchronization. A classic example of this is the Tremec 3650 transmission in the Ford Mustangs. The design has the fill plug too high in the case. If you “fill to spill” one of these units, it will not shift properly. The fix is to drain out oil until the level is 1/2 inch below the fill plug.

Other designs have low-oil conditions built in. Early models of the BW 4473 transfer case have the oil fill plug too low in the case. The fix here is to fill until it runs out the fill-plug hole, tighten the plug and then add an additional quart through the speed-sensor hole. GM has a tech bulletin out on this problem, finally.

Always check all vents in units to make sure they are not plugged, broken or obstructed.

We make and sell a very high quality of lubricants for all the transmissions and transfer cases we well. We did not do this to be in the oil business, but as self-defense. Because of the great number of special lubes now needed to operate profitably in these times, shipping the right oil with the unit prevents a lot of phone traffic that occurs after someone dumps the wrong lube in a unit to get the customer back on the road on a Friday afternoon.

If you do a steady business with a specific unit the proper lube should be in your inventory along with the other common repair parts. There are a number of lubrication guides available that will help you put the correct lube in any unit you are working on.