Up to Standards

- Author: Mike Weinberg, Contributing Editor

- Subject Matter: Bearings

- Issue: Causes of failures

All forms of transmissions, transfer cases and differentials use anti-friction bearings to support moving components, reduce parasitic power losses and maintain the parts in their correct positions for long-term reliability. The most-common bearings we see in manual transmissions, transfer cases and differentials fall into several categories of design. Each type will have different design criteria as for operational speed and the ability to handle axial (thrust) and radial loads.

The most common is the ball bearing, which is found in a huge variety of sizes and radial-load capacities depending on the size and number of balls in the bearing. Ball bearings have excellent design qualities to handle high rotational speeds but cannot handle large amounts of axial or thrust loads. Straight roller bearings cannot handle as high rotational speeds as ball bearings but because of the length of the rollers can handle larger radial loads. An adjunct to the straight roller bearing is commonly called a barrel or needle bearing because of the smaller diameter of the individual bearings. The straight roller bearing is not designed to accept axial loads.

The next area of design is the tapered roller bearing, which is usually in two pieces: the cone, consisting of an inner race, a cage to position the individual rollers and the tapered roller bearings; and the cup into which the cone fits. Tapered roller bearings have a very high capacity for both radial and axial loads and a high speed capacity close to that of the ball bearing.

Last but not least are thrust bearings, which are straight roller or needle bearings arranged in a circular cage. The bearings can take axial loads but will not tolerate radial loading and are designed to allow gears or clutch drums to work against opposing parts without deformation of the components.

Bearings are rated for a life span of revolutions under load. They are, in my opinion, part of a “soft-parts” overhaul kit when it comes to manual transmissions, transfer cases and differentials. The minimum parts needed for a rebuild or remanufacture of any of those units are new bearings, seals, gaskets and synchronizer rings. The question is, if one bearing has failed, what is the life expectancy of the others? Real-world experience should teach you that you get one, and only one, chance to sell your customer. If you replace only one failed bearing and another one goes bad under warranty, who pays for the comeback? If you build from a set of predetermined standards every time, your comeback rate will diminish at the same rate your reputation in the community increases. “There’s never enough time to do it right, but always enough time to do it over” – your choice.

Here are the main causes of bearing failures:

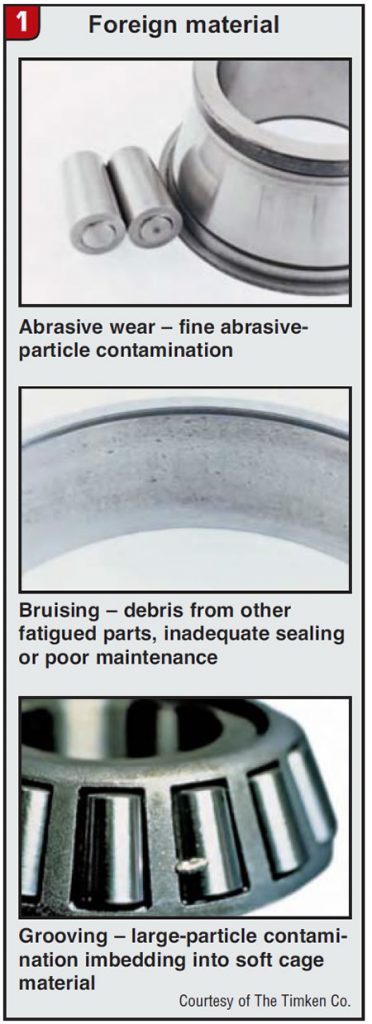

Poor maintenance practices

All machinery needs ongoing preventive maintenance to achieve a proper life span. The demand placed on the components of the average vehicle in daily driving require the owner to perform a minimum of maintenance on a schedule, which in real life is rarely followed. Oil changes are required not because the oil wears out but because it gets contaminated with metallic debris, which snatches the life out of the bearings and rotating parts (Figure 1), and because the special additive package in branded OEM-quality lubricants wears out because of heat. You should make sure that your warranty includes a preventive-maintenance schedule to keep the warranty in force. The original vehicle warranty specified the proper service schedule, and failure to do so will void those warranties.

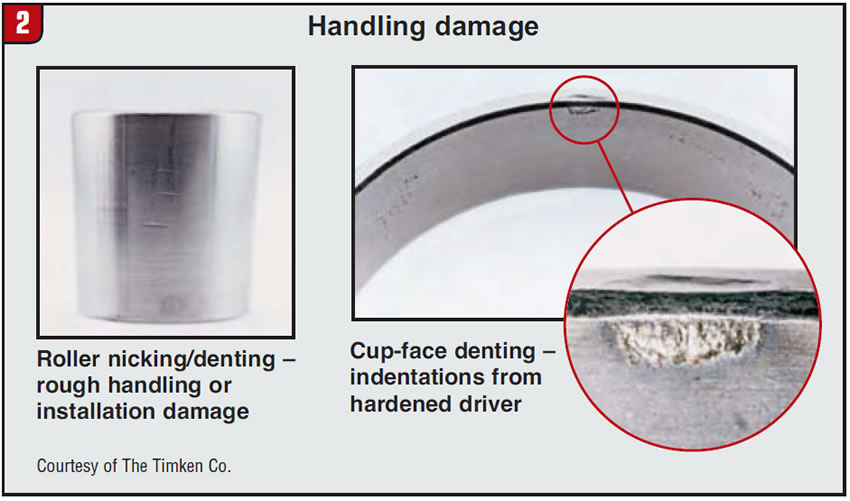

Mishandling

Many bearing failures are due to poor installation and handling (Figure 2). Damage to bearing cages in handling is very common and immediately shortens the bearing’s ability to survive. Using a punch or other straight tool to install a bearing will immediately create a future comeback. You should install bearings with a bearing driver, a section of pipe or some other tool that applies the force on the inner race of the bearing during installation. Applying force to the outer race will cause the bearing balls or rollers to “imprint” on the race, and since bearings and engine valve lifters make up the two most-precise parts in a vehicle, the bearing race has now been compromised.

Another approved trick to bearing installation is heat. Commercial bearing heaters are available, but a decent temperature-controlled toaster oven and a pair of oven mitts will make installation a snap. Heat the bearing to 300°-325°F and it will drop onto the shaft with no press or hammer work. Do not overheat a bearing, but the stated amount will expand it enough to remove the interference fit momentarily.

Do not allow a bearing to spin if you clean it and blow it off with compressed air. The bearing in operation has the balls or rollers operating on a wedge of lubricant. If you remove the lubricant and spin that bearing with air pressure, you have taken a bunch of life out of it, as it has run dry.

Another issue to be careful of is substituting

open ball bearings for sealed units. You will see ball bearings that have rubber seals and are packed with lubricant at the factory; never substitute an open bearing for a sealed one in units with sealed bearings.

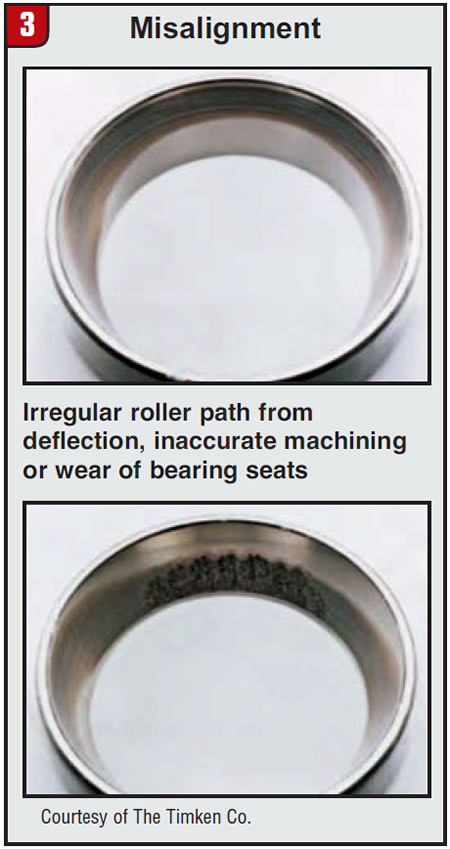

Improper installation and adjustment

Ball and roller bearings cannot live with misalignment (Figure 3). If the transmission cases are worn in the bearing bores they need to be replaced. Make sure during a repair that there are no issues with external components to the units that can cause an alignment problem. Worn crankshaft pilot bushings, missing or worn dowel pins, worn or damaged U-joints, driveshafts, engine or transmission mounts, and wiring or other components trapped between the block and bellhousing are all causes for misalignment and bearing failure.

Ball bearings rarely have issues with endplay, but tapered roller bearings must be shimmed correctly to obtain the specified endplay. Axial loads are caused by thrust loads. Helical gearing in modern transmissions generates thrust loads under throttle as the helical angles make the gears in mesh try to move away from each other, and under coast conditions they will try to contract, creating a negative thrust load. Endplay is specified to take certain things into consideration, which include the expansion of different metals at operating temperatures, the torque load put on the components and the thrust load of the gearing. If the endplay is too tight (preload) for the application, the pressure removes the lube film from the bearings, causing overheating and metallic damage. Endplay that is too loose allows the torque and thrust loads to beat the bearings into the races (Figure 4).

Lubrication issues

It is obvious by now that the correct lube is critical for proper operation and smooth shifts. Buy quality branded oils; they are worth the money compared with cheap or homemade product. Lubrication levels are critical to gearbox longevity. Too-low oil levels have an immediately impact on bearing life (Figure 5), and too much oil will cause overheating and shift problems. Sell your customer on routine service schedules, which improve your profits, create a bond with the customer and ensure that someone is checking what the customer will never do himself. Victory loves preparation.

Many transfer cases are specified to run on ATF as lube. In gear transfer cases that do not have clutch packs, the ATF will foam, become a mist and leave through the vent. Eventually the bearings fail from lack of lubricant. To save the day, replace the ATF with 5W30 motor oil, which will not mist and escape. Use only specified fluids in clutch-driven transfer cases.

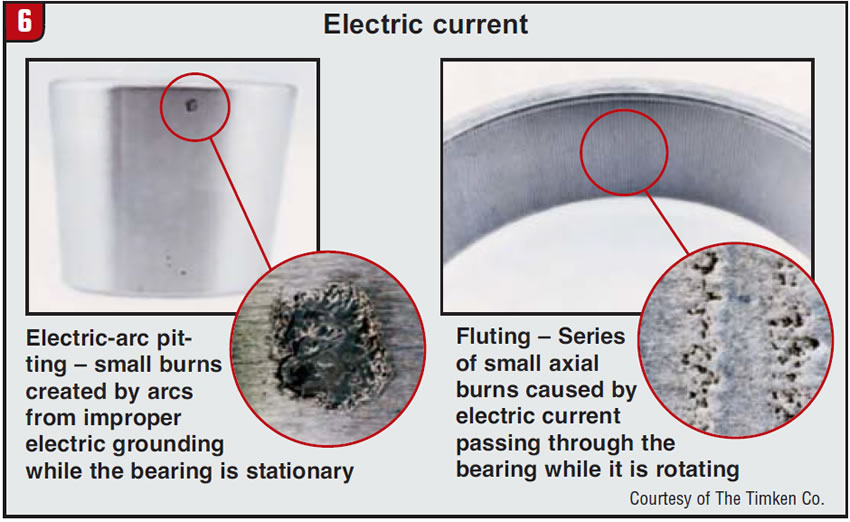

Other forces

Electrolysis occurs when a wiring issue allows a component to become a ground path (Figure 6). This is very common on wheel bearings and transmissions. As the vehicle sits idle, the current creates tiny micro welds in the bearing. When the vehicle is driven again, these welds break, and after enough time the bearing races and rollers become pitted and destroyed. Adding an additional ground strap to the transmission/transfer case will eliminate this kind of damage by giving the current a path to ground outside the unit.

Contamination occurs from either internal or external sources, water being the most common. Get to know your customers’ driving habits. People who go off road, live in areas that are flood prone or use boat ramps to put their toys in the water will go through water high enough to enter units through the vents. Sell those customers on more-frequent service, and relocate their vent tubes to higher levels in the vehicle.

Internal contamination from metallic debris can result from leaving out the magnets installed in units by the manufacturers. The metallic dust circulating in the fluid will quickly damage the bearings and other components. The automaker will never put a part in a car that is not needed, so make sure to clean and reinstall those magnetic fluid filters.

The use of an OEM-quality bearing is one of the best ways to ensure a quality rebuild. Timken, Koyo, Nachi, SKF, NTN, FAG and Federal-Mogul are just a few of the OEM suppliers. Cheap aftermarket bearings may save a few bucks, but they lack the quality and factory technical support of the OE manufacturers. Timken has a great website that will provide volumes of text and pictures to really sharpen your bearing knowledge.

Mike Weinberg is president of Rockland Standard Gear.