How Do You Repair a Transmission When Parts Aren’t Available?

- Subject: Limited availability of repair parts

- Units: HM290, 5LM60, 3500, 4500, 5600, TR-3450, TR-4050

- Vehicle Applications: Chrysler and GM light trucks

- Essential Reading: Rebuilder, Shop Owner

- Author: Mike Weinberg, Rockland Standard Gear, Contributing Editor

The media have been reminding us ad nauseam about the terrible state of the economy and the bankruptcy of GM and Chrysler. They would have you believe that these problems developed “overnight.” We who repair the vehicles know better, as for years we have watched the manufacturers make terrible design decisions and create impossible marketing moves that affect us directly.

The two most-glaring issues start with “captive product.” The auto manufacturers of today have become efficient by building fewer of the components that go into the complex and sophisticated product that is today’s automobile. Tier 1 suppliers provide many components that go into the car. Although the car manufacturer may make the sheet metal and engines and be responsible for the design and process engineering to produce the vehicle, Tier 1 suppliers like BorgWarner, Tremec, Aisin, ZF, New Venture Gear, American Axle, Dana and Eaton manufacture the transmissions, transfer cases and differentials for the driveline. Other companies produce the interiors, steering, HVAC, fuel injection and other components.

The trend for a long time has been to require these manufacturers contractually not to sell to the aftermarket parts made on tooling owned by the manufacturer. All these companies have aftermarket divisions that sell parts directly to companies like mine, which sell directly to the repair industry. The corporate thinking has been,” If we hold the parts captive to the dealer, we will control the market, get better dealership parts sales and increase profits.”

What the Detroit wizards cannot picture is that the aftermarket has to rely on a steady supply of quality parts to service the millions of car owners who will not go back to the dealer after the car is out of warranty.

A second trend that flourished under this thinking was to provide new or reman components from the dealership to replace damaged engines, transmissions etc. This solved several problems for the manufacturers: They did not have to train technicians to work on the individual components, which could simply be replaced with a complete assembly, and they did not have to stock all the service parts for each transmission, differential etc. The parts department could simply say, “Service components are not available; you must purchase it as a complete assembly.”

In certain areas this worked well. You can buy a new crate engine with a very good warranty from a number of automakers much cheaper than you can rebuild one. Where this approach goes down the drain is with older vehicles owned by people on tight budgets who cannot afford to buy a new or reman unit but could pay for labor and parts to rebuild a transmission.

The other issue that creates a marketing failure is the time element. No one wants to wait for the dealer to be able to schedule a repair, and the dealer never wanted to stock the service parts for these assemblies, as they generally are C or D movers. This is what drives people to our shops to get the car fixed quickly and less expensively. However, when parts are captive to the dealer, the aftermarket will manufacture replacement parts to get the job done. Most of the replacement parts are of good quality today, but most repair shops would welcome the choice to buy OEM if it were available.

The second huge problem we face today is the vacuum created when a Tier 1 supplier goes out of business or is no longer contractually obligated to produce service parts for past production models. A nightmare example of this is the New Venture Gear transmission line. New Venture Gear was created some years ago as a joint venture between GM and Chrysler. The companies combined the New Process Gear division of Chrysler in Syracuse, N.Y., and combined it with GM’s plant in Muncie, Ind., to manufacture five-speed manual transmissions for both companies’ pickups.

In their wisdom they bought designs from Getrag, a European gearbox manufacturer. At the time I was doing some consulting work for GM, which asked me to come to Detroit and look at the proposed design and give my opinion as to durability, service life etc. I was given an HM290 transmission to disassemble and spent the morning doing so.

After a lunch break we met in a conference room to go over my notes and discuss this design. There were 14 “suits” in the room, none of whom I knew. The most-successful manual-transmission design of the modern era was the T5, which had 14 parts in the shift mechanism and was cheap to build and simple to repair. The HM290 had 96 pieces in the shift mechanism alone, and the design was a nightmare from a rebuilder’s perspective.

I presented more than 400 design issues in the transmission and advised GM not to buy this design, as it was a catastrophe in the making, only to be told they had already bought it and had begun production. It also became apparent that I was no longer welcome there because I told the truth. They did not want to hear that “the emperor’s new clothes sucked.”

Unfortunately for them, I was correct and they were wrong. The HM290 was redesigned to become version 1 of the 5LM60. Shortly afterward it was redesigned again to become version 2 of the 5LM60. Another expensive redesign resulted in the HM3500, in which the engineers got rid of four shift rails to create a single-rail unit as I had recommended. Unfortunately, they saw fit to use straight roller bearings to support the countershaft, and there was no way to stop lateral movement of the countershaft in relation to throttle application and the tendency of helical gears to expand and contract under torque load. We have seen countershafts that can move as much as 0.250 inch in brand-new units.

Now we come to the end of this tragedy, with the joint venture being dissolved. The New Process Division had lost all its profit potential for 10 years, the GM Muncie plant was closed, all tooling and machinery were sold, and the HM290, 5LM60, 3500, 4500 and 5600 transmissions produced there were now orphans. OEM service parts were no longer available. The aftermarket provides the fast-moving service parts, but no source exists for many service parts outside of a core supplier or salvage yard. This kind of thinking and planning has left millions of GM and Dodge truck owners with limited repair options.

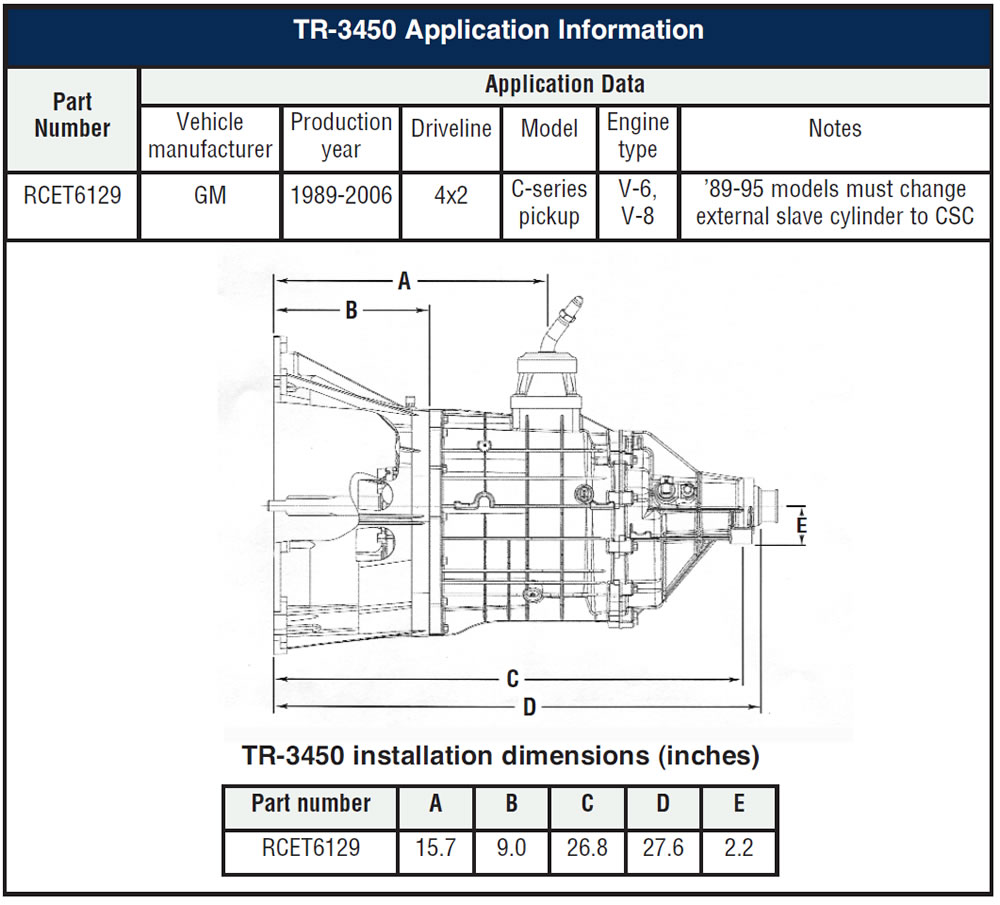

However, some alternative units now are available. Tremec, a Tier 1 supplier of transmissions, has made available direct-replacement units for the HM290, 5LM60, 3500 and 4500 transmissions. Tremec, a worldwide supplier of transmissions, has two units it sells to Chrysler and GM in the Mexican market. These are OEM units that WILL have service parts available for the next decade. At present Tremec is working on adding 4WD units to the product line, as there is no demand for 4WD in the Mexican-Latin American market. The TR-3450 is a direct bolt-on replacement for the HM290, 5LM60 and 3500 Getrag-design transmissions, and the TR-4050 is a direct bolt-on replacement for the NV 4500 heavy-duty truck transmission.

TR-3450

- Tremec part # RCET6129

- 85mm centerline distance

- High-contact, constant-mesh helical gearing for maximum strength and durability

- Die-cast aluminum housings

- Tapered bearings for all shafts to control endplay and distortion

- All speed gears supported by needle bearings for quiet operation and friction reduction

- All synchronizers feature back-taper cuts to eliminate gear jump-out.

- All forward speeds and reverse are synchronized, reducing shift effort.

- Double-cone 1-2 synchronizers for smooth, effortless shifting

- High-capacity single-cone synchros for 3rd, 4th, 5th and reverse gears

- Ratios: 3.82-1, 1st; 2.31-1, 2nd; 1.42-1, 3rd; 1-1, 4th; 0.83-1, 5th (overdrive)

- 10-spline input shaft, 32-spline output shaft

- Electronic speedometer drive

- Dry weight – 114 lbs.

- Torque rating – 335 lb.-ft.

- Available at present in 2WD only

- Note: 1989-95 models must change from external slave cylinder to internal concentric slave cylinder; part number available on request

- Engine type: V-6,V-8

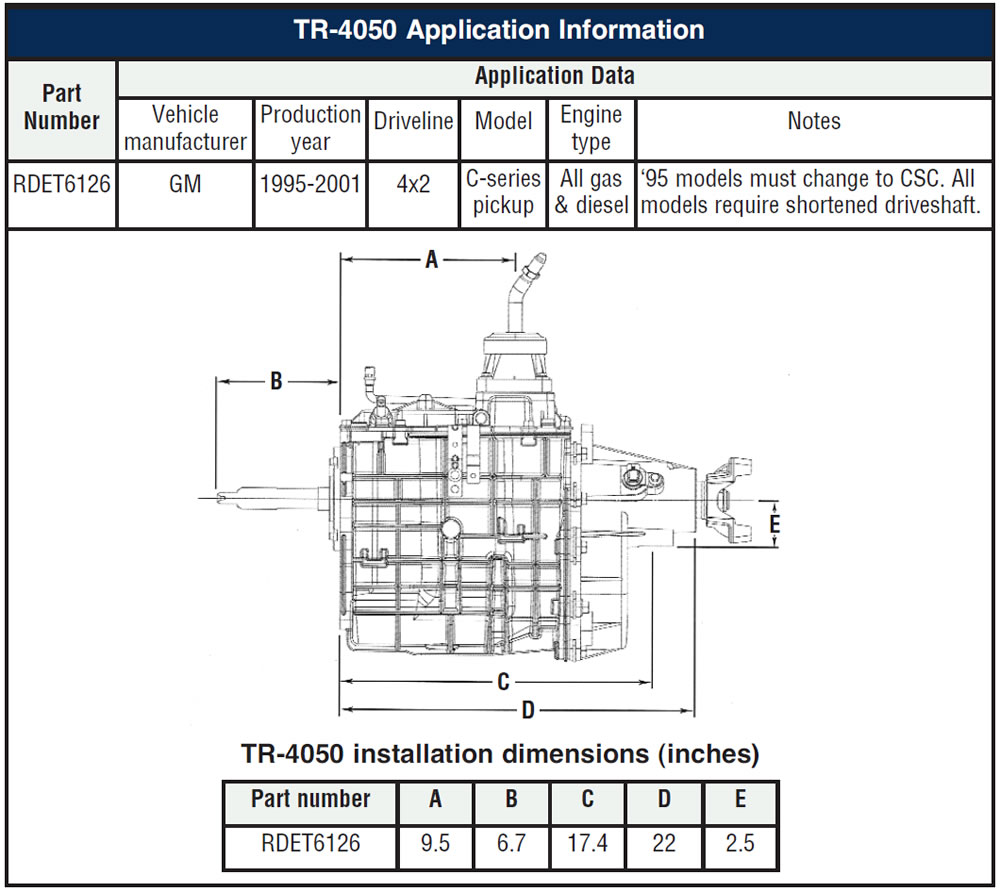

TR-4050

- Tremec part # RDET6126

- 109mm centerline distance

- Constant-mesh, high-contact helical gearing for maximum strength and durability

- Die-cast aluminum housings for weight reduction from cast-iron 4500

- Right-hand-side standard PTO opening for hydraulic pumps

- All shafts supported by tapered bearings

- All speed gears supported by needle bearings for reduced noise and friction

- Redesigned 5th-gear retainer eliminates movement of the 5th-gear locknut common to 4500 units.

- All forward gears and reverse fully synchronized

- State-of-the-art synchronizers for smooth shifts and reduced shift effort

- 5th gear mounted on countershaft to reduce noise in overdrive at highway speed

- 10-spline input shaft, 32-spline output shaft

- Ratios: 5.81-1, 1st (extra low); 2.94-1, 2nd; 1.61-1, 3rd; 1-1, 4th; 0.77-1, 5th; 5.69-1, reverse

- Electronic speedometer drive

- Weight with lube fill – 169 lbs.

- Torque capacity – 480 lb.-ft.

- Available at present in 2WD only

- Engine type – all gas & diesel

- Note: 1995 models must change external slave to internal concentric slave; all models will require shortening the driveshaft

A knowledge of history helps us anticipate the future. There will be many dislocations coming in the parts supply we depend on to get our customers back on the road.

For example, two huge suppliers – BorgWarner and New Venture Gear – have undergone major changes in the past few years. Magna International bought New Venture Gear and New Process Gear from Chrysler.

This has caused a great number of parts and assemblies to be unavailable. For example, almost no parts are available for the NVG 246, 261 and 263 transfer cases. All these units tend to have case failures, and supply of new cases is non-existent. We are working on a solution to be able to provide repair shops with quality replacement parts.

BorgWarner has closed its plant in Muncie, Ind. This was a huge factory with more than a million square feet under one roof. Expect delays in parts supply as the company relocates its operation to other plants.

We also can expect all manner of complications arising from the bankruptcy and reorganization of Chrysler and GM as the supply chain gets reorganized. Availability of critical parts will continue to be limited until the manufacturers start putting their customers first. We as small-business owners know that if you don’t take care of the customer, pretty soon you don’t have many customers to worry about. One can only hope that the carmakers will start to change their ways. Anytime a customer cannot get his vehicle repaired quickly at a reasonable price, it is the brand name that gets the blame, and sales disappear.