TASC Force Tips

- Author: Jim Dial, Sonnax Engineering and Technical Services

- Subject Matter: Diagnostics

- Unit: JF011E CVT

- Vehicle Application: Renault, Mitsubishi, Suzuki

- Issue: Bearing Noise

Bearing noises can be difficult to track down even in familiar transmissions which we work on daily. The advantage of the familiar is that we know how to take these units apart and have a general idea of power flow and overall operation–plus, we typically have plenty of extra pieces on the shelf should we need them. Bearing noises in the CVT transmission are much harder to deal with, because we’re not as familiar with it as the units rolling in the door on a daily basis and spare CVT pieces are pretty much non-existent. This has created some minor paranoia when it comes to taking on a CVT repair. Hopefully this article will dispel a bit of the apprehension regarding these units and prove that–with the right tools and a little know-how–CVTs can be repaired and become decent money makers for a shop.

The most common abnormal bearing noise concern with the JF011E is related to a rotational whining noise in Forward or Reverse. The noise gets worse as vehicle speed increases and sometimes it may even sound like a differential noise. A pan examination will reveal a magnet with a good amount of steel hair on it, which means there is something “making metal”. This happens when the pulley bearing races become pitted, causing metal flaking. To address the problem, the bearings must be replaced, and that requires unit removal.

Once the transmission is out of the vehicle, remove the valve body so that the ratio-control motor and arm can be disconnected from the ratio-control motor follower. Next, detach the rear cover and pulley assembly from the case. Once the rear cover is removed, take out the bearing retaining bolts (Figure 1) so the pulley assemblies and belt can be removed from the cover.

Wrap two nylon zip-ties around the belt (Figure 2) BEFORE removal to prevent it from falling apart (not a good situation!).

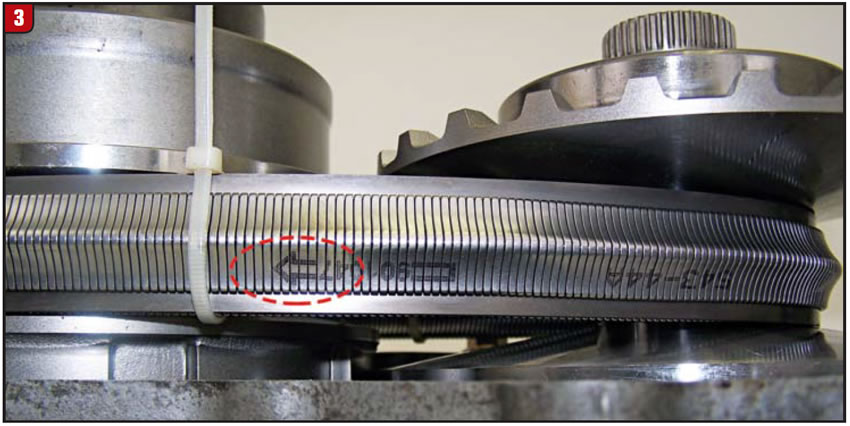

Figure 3 shows a close-up of something to be aware of: the arrow on the belt shows the correct direction of rotation. You’ll need this for reference when the belt is reinstalled into the pulley assemblies, because putting the belt on backwards will damage it and the assemblies.

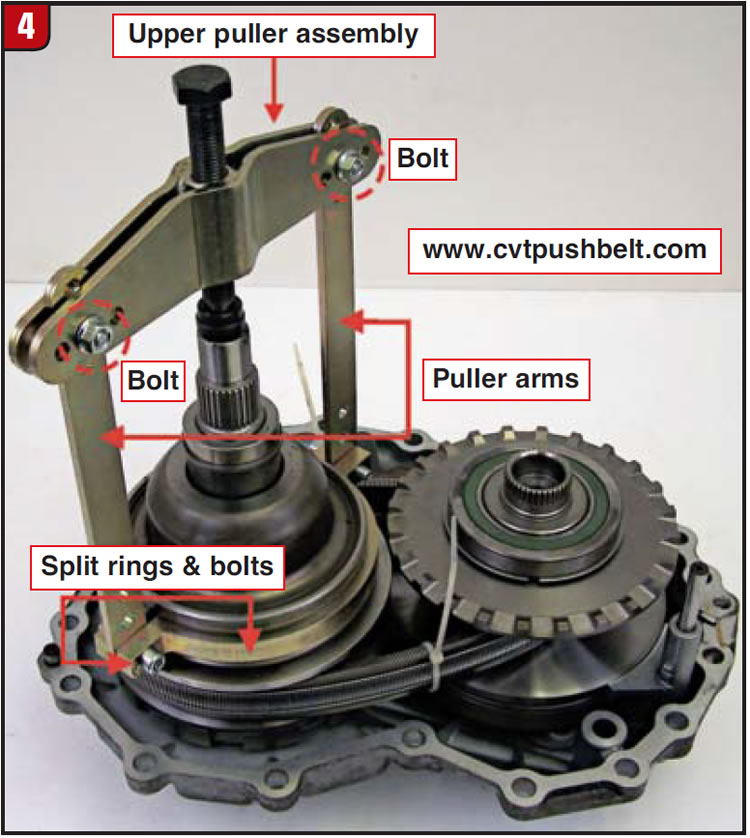

The next step is to open up the secondary pulley so it can be removed, but first you need to have the right tools on-hand. The secondary pulley has a large spring inside that must be compressed before the pulley can be opened. The tool kit for accomplishing this and related parts to complete the process are available in the aftermarket and well worth it. They work as follows:

A split-ring is bolted around the bell-shaped area of the secondary pulley and two arms are connected to the split-ring retaining bolts.

The upper puller assembly and threaded bolt are attached to the top of the arms with two bolts and nuts (Figure 4).

Once the split-ring and upper part of the puller is set in place, tightening the center bolt will relieve spring tension and allow opening of the secondary pulley (Figure 5).

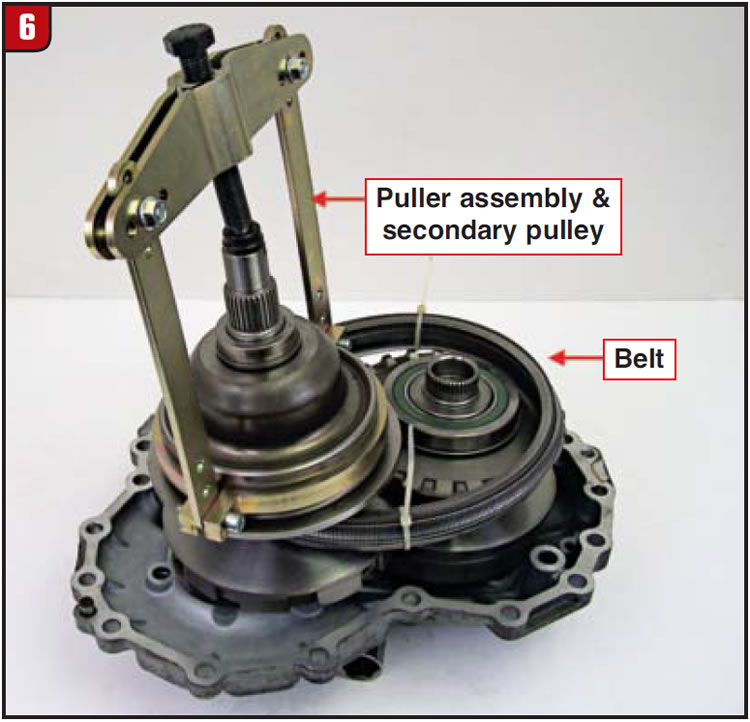

Lift the puller assembly and the secondary pulley out of the cover, then place it inside the primary pulley opening (you may want to put a rag over the primary pulley face to prevent scratching).

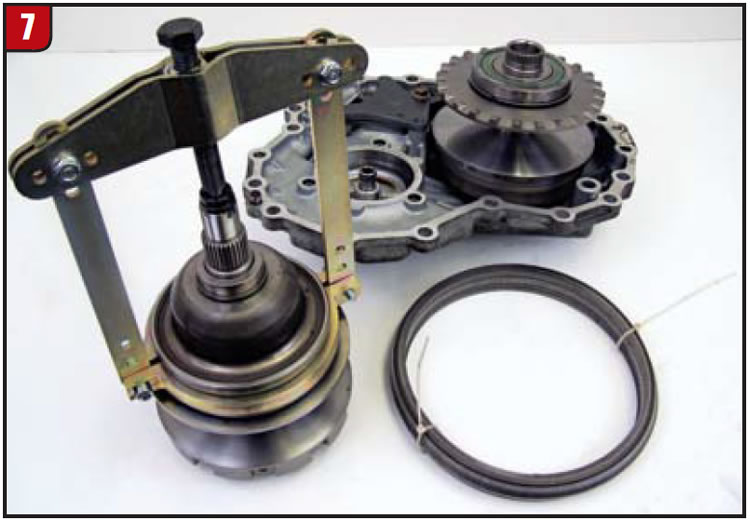

Now, lift the belt over the primary pulley and remove from the cover (Figures 6 and 7).

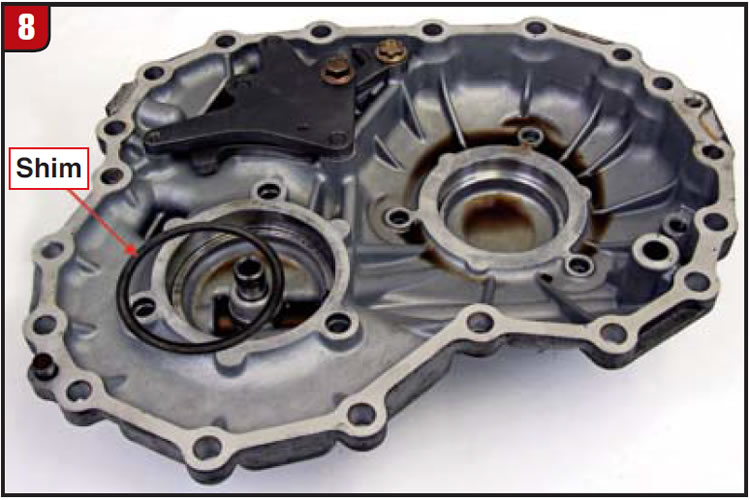

Some units have shims between the rear cover and bearing (Figure 8) which need to be saved for use during reassembly.

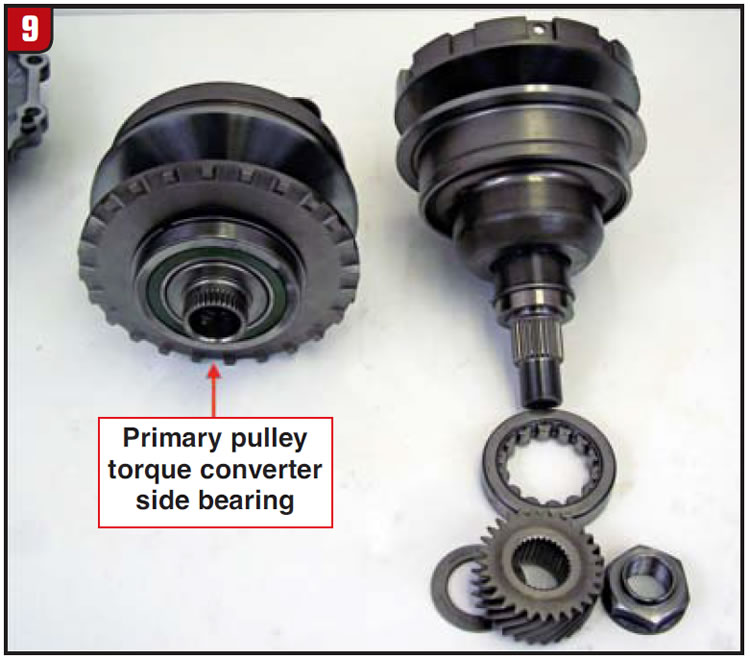

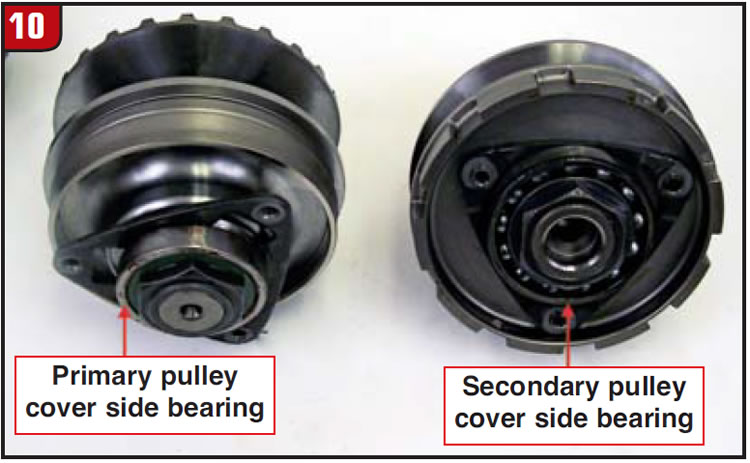

Figures 9 and 10 show the location of the bearings on both the secondary and primary pulley assemblies. There is a primary pulley bearing for the torque converter side and one for the cover side, along with a cover-side secondary pulley bearing. These bearings can be removed with a two-jaw bearing puller or a bearing splitter and puller assembly and pressed back into place with ease. Replacement bearings are readily available in the aftermarket for both JF011E and JF010E units.

Reassembly of the pulleys and belt back into the cover is a snap: simply reverse the process we just went through.

You can see now how easy it is to replace bearings on the JF011E, and once you’re inside the unit you’ll find the rest of the transmission isn’t so scary either. With a little knowledge and the right tools, chasing down noises and repairing CVTs can be very profitable–even if they don’t roll in the door every day.

Jim Dial is a Sonnax Technical Specialist and a member of the Sonnax TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians. He will be a seminar speaker on March 13 at the 2015 Auto Tech Expo in Jacksonville, Fla., presenting a further exploration of the Nissan CVT. ©2014 Sonnax Industries