Up to Standards

- Author: Mike Weinberg, Contributing Editor

The daily grind of repairing transmissions and transfer cases has always been demanding. The level of expertise necessary to be successful in the present market is matched only by the level of salesmanship it now takes to sell expensive repairs against a new-car market that is a buyer’s market.

It is easy to lose one’s way and become embroiled in solving problems that actually do not exist. This is where the development of a proper diagnostic method of thinking a problem through before actually turning a wrench is a must. We as technicians are always guilty of attacking the unit when any number of external forces can create the problem that has shown up while it’s under warranty.

The fact that we took the customer’s money and we have the vehicle often deludes us so that our immediate reaction is that the problem must be “in the unit.” With the state-of-the-art electronics that comprise late-model vehicle systems, there is every reason to believe that the last place you should look will be the unit.

Last month we discussed working “outside in,” which means to look at all external possibilities for the problems before pulling the unit. This is always the cheapest way to work, as it consumes the least time – and, therefore, money – and logic dictates that once you have found all external areas of fault to be operating correctly, the last item, the unit, must be the cause.

Unfortunately, in many instances the first area looked at is the unit, and any external problems never get solved. This wastes a lot of time and money, and until we eliminate this type of thinking, none of us can grow and move on to the next level of expertise.

We will discuss here a number of common problems that have many shops spinning their wheels because they are not thinking outside the box. The first example is the sad saga of a BorgWarner transfer case, model 4406, that was part of a 1999 Ford Expedition. The customer who owned the vehicle was on an extended tour of the United States and experienced a transfer-case problem while in Michigan. They took their vehicle to a shop that was part of a nationally recognized franchise chain, where it was diagnosed and a remanufactured transfer case was ordered to repair the vehicle.

The vehicle was locked in four-wheel drive at all times. The replacement transfer case arrived and was installed, the vehicle was road tested, and the customer left to continue their journey. Several weeks later the vehicle was taken to a shop in Texas, under the national warranty, with the same problem – locked in four-wheel drive. The company contacted the provider of the remanufactured transfer case, which promptly shipped a replacement to the Texas shop to get the customer back on the road. The second transfer case was installed, the vehicle was road-tested thoroughly, and again the customer was back on the road.

Several weeks passed, and the same vehicle arrived at a shop in Florida, the owner’s home state. Again the vehicle was locked in four-wheel drive at all times. The Florida shop then contacted the supplier of the transfer case and asked for another unit to be sent under warranty.

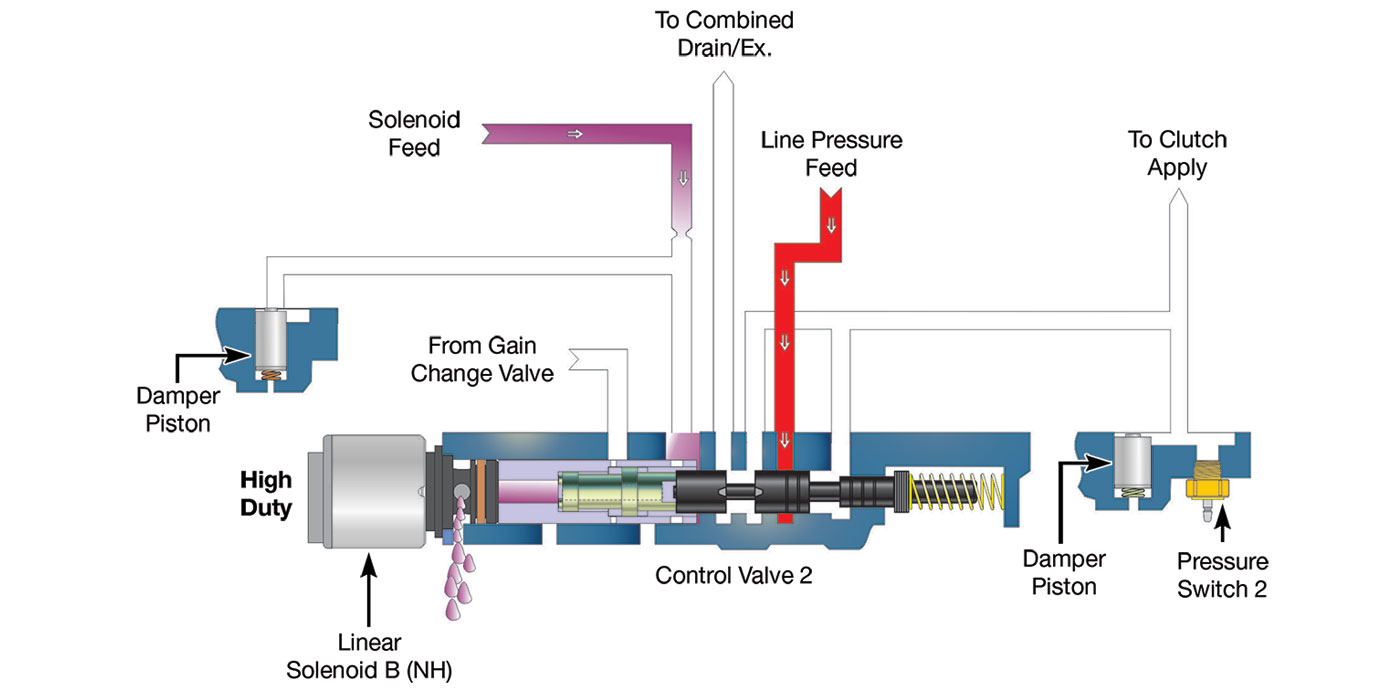

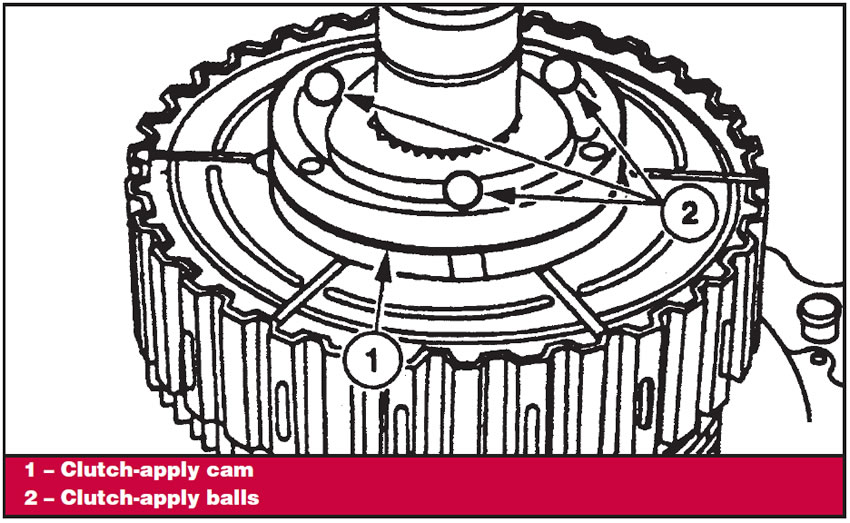

At this point the transfer-case remanufacturer had received the core for the transfer case that was replaced in Michigan and the warranty-return unit from the Texas facility. Both units had been disassembled completely after being tested, and there was actually nothing wrong with either unit, except that the balls and cam that apply the clutch pack (see illustration) were wedged in the full apply position and could not be released without disassembly. This is a common situation in the 4405 and 4406 transfer cases when they are driven in the full four-wheel-drive position on dry pavement for an extended period.

Now fully aware of the effect on the transfer case of an undiagnosed problem in the vehicle, the transfer-case remanufacturer sent a third unit to the Florida shop and explained the situation to the Florida technician. The transfer case was installed, and the Florida shop owner took it home for the weekend to try to isolate the external problem. The unit again went into full four-wheel-drive and the shop was unable to locate the cause.

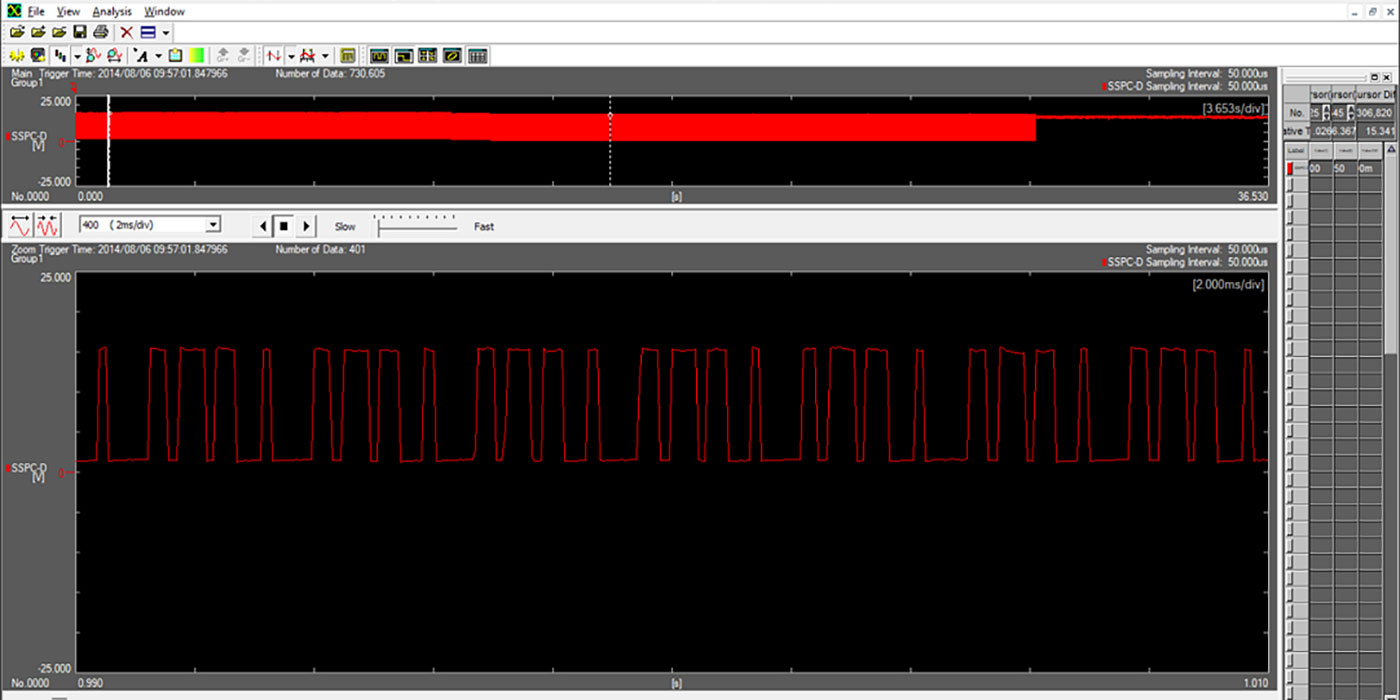

The shop then sent the vehicle to a local Ford dealer for diagnosis. The Ford dealer was able to locate a broken ground wire in the transfer-case harness, and when that was repaired the vehicle operated correctly. The loss of ground on the circuit (unknown at this point) caused the computer to signal full clutch apply, creating a full-time 100% duty cycle on the clutch pack, and the continuous operation on dry pavement wedged the balls and the apply cam into terminal lockup.

This is a prime example of an external cause creating multiple problems with a unit that had nothing wrong with it. I do not know why the three shops involved could not find the bad ground, nor do I know how the Ford dealer was able to solve the problem relatively quickly. Perhaps there was a difference in the quality of the diagnostic tools used, or maybe the Ford technician had seen this problem before and knew what to look for. There is no blame here, and no one is meant to be held as guilty. This is just an example of an incredible amount of wasted time and money for all involved, all because of a pattern of thought that always makes the unit the first place to look, instead of the last place after every conceivable external factor has been examined.

Solutions to Other Nasty Transfer-Case Problems

NV136

This is a clutch-driven all-wheel-drive transfer case. This unit is particularly sensitive to the condition of the fluid and the size and pressure of the tires. When the fluid breaks down, the transfer case will react to the loss of the fluid additive package by binding on turns.

The cure is usually a multiple-step procedure, the first of which is to make sure all tire pressures are equal and that circumferences at the center of the tread are within 1⁄4 inch on all four wheels. The second step is to replace the fluid and add a bottle of Lubegard Red fluid additive. Have the customer drive the vehicle for about 300 miles. It will take this long for the new fluid to replace the old fluid in the clutch material. After 300 miles either the unit will work correctly or you will need to disassemble the transfer case and replace the clutches.

NV247J

This is an “automatic” transfer case that uses clutches and a pump coupler to provide pressure to apply the clutch pack when needed. The pump coupler is a sealed unit that cannot be rebuilt or repaired and, as with most replacement-only items, is expensive. These transfer cases will tend to bind on turns. After making sure that tire pressures and circumferences are all equal, check the fluid. If the fluid is low or badly discolored, you can be sure that the pump coupler has gone to the great scrap yard in the sky. Use only 247M fluid in this unit.

NV231J

Premature chain failure. Before the 1994 model year, all the Jeep models that used a 231 transfer case had a front-axle disconnect, so that when the vehicle was in two-wheel drive the front driveshaft was not turning. Starting with the 1994 model year, Jeep eliminated the front-axle disconnect so that the chain is turning through the front prop shaft any time the vehicle is in motion.

The factory fill on these units is ATF. When the chain whips the ATF at high speed, the fluid becomes a vapor and leaves the transfer case through the vent system. A combination of low oil and overheating stretches the chain and the unit is junk. Anytime you see one of these units with a brown discoloration on the inside of the case and a brown chain, you know how it happened.

Another cause of this is the owners who drive their vehicles in four-wheel drive on dry pavement. It doesn’t take too much of this at highway speeds to have a meltdown. These part-time units should never be driven in four-wheel drive on dry pavement. The cure for the part of this problem you can control is to fill these units with 5W-30 motor oil. Because of its higher viscosity, the motor oil will not vaporize and leave through the vent, and the transfer case will last much longer.

All-wheel-drive transfer cases with viscous couplings

BW 4472 & 4404

Viscous-coupling failure – These units are extremely sensitive to tire size and tire pressure. Running the vehicle with tires of different circumferences will cause the fail the viscous coupling to fail in short order. Also check for stripped axle splines, which will have the same effect. If the unit binds on turns, the coupling is done.

To check the viscous coupling, place it on the shaft. Hold the shaft in a soft-jawed vise and use the lock nut to turn the coupling with a torque wrench. If you can turn it with 65-250 lb.-ft. of torque, it is useable. If the viscous coupling is locked up, buy a new one. If under hard acceleration one of these units bangs in the driveline, replace the chain and planetary.

BW4405

Multiple areas to be observed:

A high-pitched whine after installation is caused by the front or rear speed sensors not being installed flush and hitting the tone wheel. Would you be surprised to know that we get this call five times a week? It is easy to install the speed sensors in a cocked position. Lubricate the O-rings thoroughly and install with a twisting motion to make sure they are flush to the case.

Binding in Auto two-wheel drive on turns – Measure tire circumferences and check air pressure.

Bad speed sensors or speed-sensor circuits – Any time any sensor or electrical-circuit plug is disconnected for repairs or diagnosis, be sure to reset the GEM by disconnecting the negative battery lead before driving or checking for codes.

Ghost shifts – This is an unrequested shift from high into low at speed. This usually breaks the shift fork. This “ghost shift” to low violates all safety parameters designed into the unit. To obtain a shift to low, the vehicle should be in neutral with the brake switch actuated and at a speed of no more than 3 mph. For this shift to occur on its own, there has to be a short to power in one of the harnesses. The usual suspect is the short harness under the driver’s seat. This is common enough that a lot of shops stock this harness. If this shift occurs for the customer, make sure that you inspect the transfer case internally, as there will be damage to the low-range fork and shift collar.

T56 transmission

Broken 3-4 shift keys, 3-4 synchro locked in 3rd or 4th, hard-shifting problems – The problem always starts with a bad clutch release. This may be caused by a bad clutch, worn hydraulics or a driver who rushes the shifts. This means he is moving the shift lever before the clutch has disengaged and spun down, a common problem with performance-oriented cars and drivers who are trying to impress their girlfriends.

A pro knows that it takes a little time for the clutch to disconnect and spin down, releasing the input shaft. The amateur driver will beat the clutch release or try to “power shift,” with the 3-4 synchro keys giving up their life. If you have solid keys made, he will just break the synchro hub in the future.

These are some shortcuts to let you see how many internal problems result from external causes. See the whole picture, as sometimes when it is hot and heavy in the trenches you can’t see the forest for the trees.