TASC Force Tips

- Author: Ed Lee, Deltrans

There was a time when the only fact that you had to know about a one-way clutch was the direction in which the clutch freewheeled. Today you also must be able to troubleshoot some difficult problems related to one-way clutches.

Early on, technicians realized that you could bypass a one-way clutch by engaging a clutch or band that holds the same member that the one-way clutch holds. You can easily isolate the one-way clutch in a rear-wheel-drive or three-speed front-wheel-drive Chrysler transmission by placing the transmission into the manual-low range. In the manual-low range the rear band is applied. The rear band now helps to hold the drum that previously was held by only the low roller clutch. If the vehicle moves in manual-low range but did not move in the other forward ranges, you know that the low roller clutch was not holding.

You can isolate the launch shudder in a 700 transmission in a similar manner. By placing the transmission into the “D” or “3” range, you are applying the overrun clutch. If the launch-shudder condition is not present when the transmission is in the “D” or “3” range but was present in the OD range, the input one-way clutch was not holding.

In 1999, ATSG’s Wayne Colonna gave his “X-Files” presentation. One important point of his presentation was how an input sprag can affect the 2-3 shift on G4A-EL and F4EAT transmissions. This fact later was reinforced by John Pifke’s “We Know It’s Not the Input Sprag” article in Transmission Digest, February 1999. This condition also can occur in other front- and rear-wheel-drive transmissions with the same power flows (e.g., 700, RE4RO1A). In all the transmissions with this type of power flow, you can isolate the 2-3 flare by shifting the transmission into either the “D” or “3” range. In some instances when a manual “D” or “3” range is not available, it may be necessary to depress the overdrive-cancel button. Both methods will engage the overrun clutch. If the 2-3 flare is not present when the overrun clutch is engaged, the input one-way clutch is not holding.

The only exception to this rule is the JR403 transmission. Since the overrun solenoid in the JR403 is controlled in connection with the throttle-position sensor (TPS), the overrun clutch is applied only about 10% of the time that the overdrive-cancel button is depressed. For this reason, you may see an isolated good shift. To apply the overrun clutch on the JR403 transmission, find pin #21 on the control unit (usually behind the glove box). Cut the wire about 3-4 inches from the control unit. Cutting the wire to the overrun solenoid turns off the solenoid. When the solenoid is off, the overrun clutch is on. If the 2-3 flare is not present when the overrun clutch is on, the forward one-way clutch was not holding.

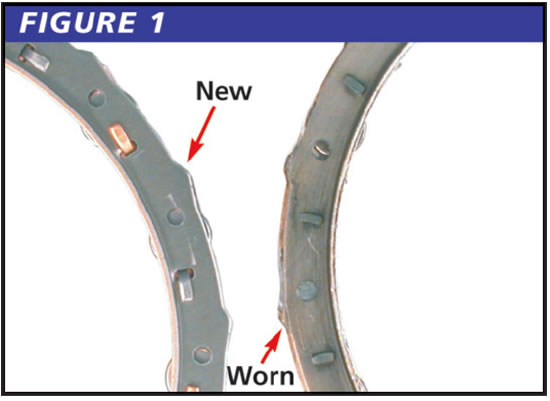

Other one-way-clutch problems occur when the cages that hold the springs and rollers start to wear. Figure 1 shows a new cage on the left and a worn-out cage on the right. The worn cage was in a 700 transmission. The customer complained that the vehicle had harsh forward engagements and that the 2-1 downshift felt as if you were being rear-ended by a tractor-trailer.

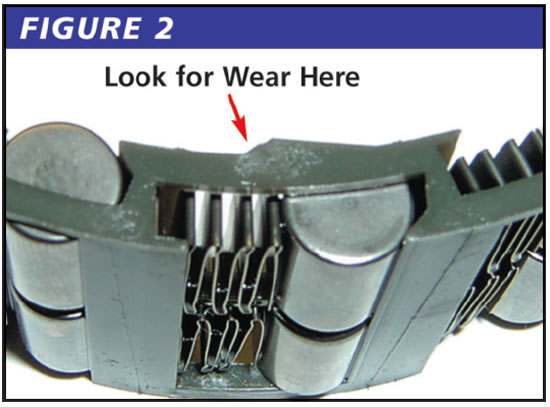

The worn-out cage in Figure 2 was in a rear-wheel-drive Chrysler 518 transmission. This customer complained about an intermittent 3-4 flare. To check the amount of wear on the roller-clutch cage, install the cage into the housing without the inner race. Check the distance that the worn cage rotates and compare that with the rotation distance of a new cage.

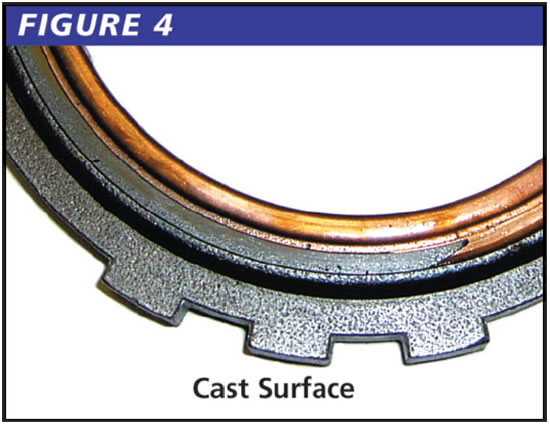

Front-wheel-drive Toyota transmissions historically have had a low roller clutch with a machined surface on one side (see Figure 3). The opposite side of this low roller clutch traditionally has had a raw-casting appearance (see Figure 4). The factory and ATSG manuals refer to loading the one-way clutch from the shiny (machined) side.

On some of the late-model Toyota front-wheel-drive overdrive transmissions, the low roller clutch now is machined on both sides (two shiny sides). The old dogs of our industry will have to pay particular attention to this. Just because the shiny side is up does not mean that the sprag is installed properly.

Hope this helps you with your one-way-clutch problems.

The TASC Force (Technical Automotive Specialties Committee) is a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians.