Tech to Tech

- Author: Craig Van Batenburg

- Subject Matter: Serviceability

- Vehicle Application: 2014 Chevy Impala

- Issue: Service comparison

After GM went through a public bankruptcy, did its cars get better to service?

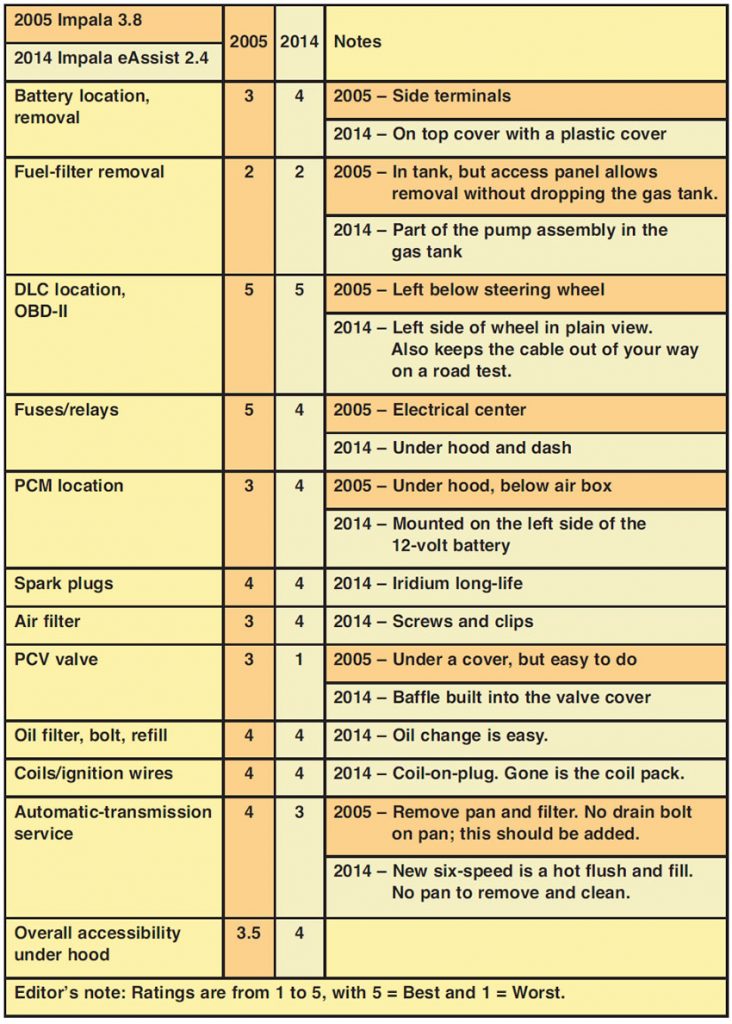

This month, we focus on the Chevy Impala for the second time. Back in 2005 I compared the 3.8 four-door sedan with a model-year (MY) 2000. As I have said many times, I will not let my bias change the real story. In 2005 my bias was against GM as it was building gas-guzzlers and had few innovations. Now I am watching a company move into some high-tech solutions, like the Spark EV and the Volt. GM and Alan Nagel, a GM trainer in Canada, are making a believer out of me.

The first Impala

With a six-cylinder engine, a 1958 Chevrolet Bel Air Impala started at $2,586; $2,693 bought an eight-cylinder. MY 1958 was the first year of production as Impala signaled Chevrolet’s entry into the mid-price field. Little did the company know 55 years ago that cars named Camry and Accord would upset the ranking of its car with fins and a V 8. Today we have the 10th-generation Impala. It was updated for MY 2014 and was the first American sedan in 20 years to earn Consumer Reports’ top score. This updated version, which I saw at the New York Auto show April 4, 2012, is larger and more lavish than the existing model.

Is GM a new company?

The new Impala models went on sale to the public on April Fool’s Day, 2013. The eAssist versions will go on sale late this year. Consumer Reports wrote, “It has been transformed from a woefully uncompetitive and outdated model that was to be avoided even as a free upgrade at the rental-car counter into a thoroughly modern and remarkably enjoyable vehicle.” I have noticed as I have traveled to Detroit many times since 2009 that the GM people I come in contact with have humility about them. When I tell them I was a Honda owner ever since I bought a 1974 Civic (and Honda motorcycles before that) and now I own a Chevy Volt (and love it), they thank me for taking a chance and buying a Chevy. So how good is this new 2014 Impala?

2014 Impala

Chief engineer Todd Pawlik’s team had a lot to do. The car segment was very advanced except for the old Impala. What they did was truly a transformation. The GM engineers designed and built a roadworthy Impala without expensive solutions – very “Honda” of them. Chevrolet didn’t use the special HiPer-strut front suspension used by Buick and Cadillac. Instead, the front shocks (finely tuned conventional twin-tube components) and a multilink rear suspension were bolted directly to the unibody. They added urethane jounce bumpers and rebound springs to supplement the front coil springs and provide a great ride while keeping body motion under control. Electrically assisted power steering helped fuel efficiency and is also required when the eAssist hybrid system is ordered, but it is on all models.

eAssist

Mated to the 2.4L Ecotec direct-injection four-cylinder engine and next-generation six-speed automatic transmission, the eAssist system uses power stored in a large battery to provide needed electrical boost in various driving scenarios, optimizing engine and transmission operation. An advanced 115-volt lithium-ion battery and latest-generation 15-kW induction motor-generator unit help increase fuel economy with the usual regenerative braking, which provides up to 15 kW of electricity to charge the battery and provides up to 11 kW (15-hp) of electric power assistance during acceleration.

The automatic engine shut-off when the vehicle is stopped and fuel cut-off during deceleration down to zero vehicle speed along with the charge and discharge of the high-voltage battery is typical hybrid fare. The eAssist delivers electric boost to the powertrain system during heavy acceleration and grade driving, enabling the engine and transmission to operate more efficiently.

It also features a “hill-assist” system that captures brake pressure to help the driver more comfortably accelerate from a stop on a moderate or steep grade. It does this by greatly reducing the tendency of the vehicle to roll backward with the engine in shut-down mode. While in fuel shut-off mode, the induction motor-generator unit continues spinning along with the engine to provide immediate and smooth take-off power when the driver presses on the accelerator. Then, as the vehicle comes to a stop, the induction motor-generator unit spins the engine, bringing it to a smooth stop, properly positioned for a smooth restart.

The eAssist power pack contains the lithium-ion battery pack, the integrated power inverter and 12-volt power supply. It is situated in a compartment between the rear seat and trunk, and it is surprisingly compact and lightweight, weighing only about 65 pounds. A quiet electric fan cools the power pack, drawing air from a vent in the package tray, behind the rear seat. The eAssist system’s electric induction motor-generator is mounted to the engine in place of the alternator to provide both motor-assist and electric-generating functions through a unique engine-belt drive system. The induction motor-generator is a high-performance, compact induction motor that is liquid-cooled for increased performance and efficiency. It also uses a 12-volt starter on initial startup.

Next-generation six-speed

The next-generation Hydra-Matic 6T40 features make the powertrain more efficient. Significant internal transmission changes to clutch controls and hardware provide reduced spin losses while improving shift response and time. The added electric power provided by the eAssist system allows for higher gearing to improve steady-state efficiency without affecting acceleration performance or drivability. The system’s ability to provide some electric assistance at cruising speeds allows the driver to accelerate lightly or ascend mild grades without the transmission downshifting.

An auxiliary, electrically driven transmission oil pump is added to the 6T40, which keeps the transmission primed and the fluid flowing when the engine shuts down at a stop. That keeps the transmission ready to perform when the driver accelerates.

2005 Impala

The 2005 Impala with the 3.8 was a good engine, but the car was not the most powerful, fuel efficient, clean or high-tech. The technicians who work on these all day just go about their work. Service is easy, after tricks are learned, like changing the air filter. It looks easy, but the first time is frustrating, as you fight with the intake hose. It could be a lot easier to replace. As I said in 2005: “A car with such a historic name sure deserves more car buyers than this. What is keeping the average buyer away?” Overall, the 2005 was a plain car, not a bad design, but old fashioned. Looks like the 2014 may change the old story.

Summary

As I look back, I have evaluated the Silverado, Malibu, Corvette, Cruze and the Saturn Division (now discontinued). What is your pick for serviceability on any motor vehicle you have serviced? Email me at [email protected] and vote for the best service design you have seen on any car, van, SUV or truck sold in the United States since 1996. I will report the survey in the future. Until then, remember: It is harder to fix them than it is to design them. Keep up the good work.

Craig Van Batenburg, AAM, is a master hybrid technician. He was the owner and lead technician for more than 25 years at his own shop that specialized in Honda and Toyota vehicles. Van Batenburg was the president of ASA Massachusetts from 1993 to 1996. He is owner of the Automotive Career Development Center (ACDC), which he founded in 1998. He develops technical classes for those who require updating their knowledge in hybrid and electric cars. Some of his customers include the U.S. Army, U.S. Marines, Delphi, Midtronics, John Deere, Porsche of America and BG Products. You can reach Van Batenburg at [email protected].

This copyrighted article is reprinted with the permission of AutoInc., the official publication of the Automotive Service Association (ASA). To learn more about ASA and its commitment to independent automotive-service and repair professionals, visit www.ASAshop.org or call 800-272-7467.