TASC Force Tips

- Author: Gregg Nader

We’ve heard many times how we can fix transmission problems by reprogramming the computer and how important it is to check for updates when dealing with a new problem or symptoms. Most of the technical-information sources have been preaching this for several years now, but it is important to note that you cannot rely on traditional service bulletins for complete information on vehicle-software updates. It takes way too much effort and money for the car manufacturers to document every software update with a service bulletin. So if you are dealing with an unusual problem, just checking for bulletins is not good enough. I suggest you go directly to the OEM source to see whether there are any revisions to the computer software for the vehicle you are working on.

GM makes this easy and free on the Internet at http://calid.gm.com. For anybody who has not checked out this site, I strongly recommend that you familiarize yourself with it. It provides the software identification numbers and shows whether updated software is available for the vehicle identification number (VIN) you enter. It is information only and does not allow you to reprogram directly. That must be done with dedicated equipment. For other manufacturers, you must rely on dealer contacts to help determine whether updates are available. It would be nice if more manufacturers followed GM’s lead and made this information easily accessible, especially when it affects vehicle durability.

One type of software update alters the sensitivity to setting trouble codes, sometimes referred to as nuisance codes. The new software may adjust the parameters necessary for a code to trigger and prevent troublesome warning lights and failsafe mode in an otherwise properly working vehicle.

Another type of reprogram changes the actual operation of the unit to improve durability or drivability. The story that follows is this second type of reprogram. It involves a 2001 full-size GM van with a 4L60-E and a complaint of an intermittent squawk/slip in reverse. It had been bounced around to various shops and dealers with the same complaint. During parking-lot maneuvers with the vehicle hot, occasionally there would be a squawk in reverse when the driver pushed the throttle. This was not a rolling engagement into reverse: rather, it was a normal shift into reverse with a slight pause and then depressing the throttle, and away it would chatter.

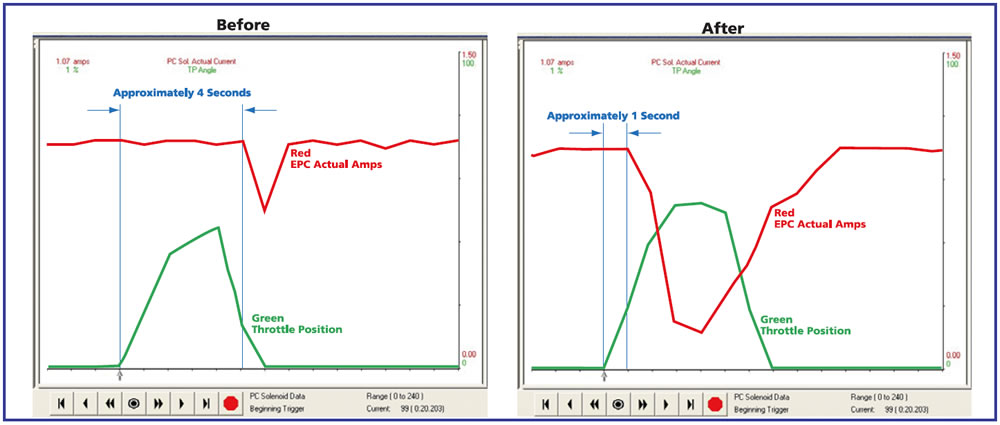

With a pressure gauge installed, it seemed as though line pressure did not respond immediately, but once pressure did rise, the squawk/slip stopped. The worse the pressure delay, the worse the squawk/slip was. It was definitely a pressure-rise problem and seemed it was internal to the unit until a technician used a graphing scan tool to compare the signal from the computer to the electronic-pressure-control (EPC) solenoid with the throttle percentage indicated by the throttle-position sensor (TPS). There was a delay of a couple of seconds from the moment the throttle was depressed to when the computer commanded a change in EPC pressure. The time of the delay corresponded to when the unit was slipping, squawking and chattering.

This unit already had a new pump, a different valve body and EPC solenoid, and the rest of the unit had been thoroughly checked. The vehicle was at a dealership, and there were no bulletins that described this or similar problems. Checking for software updates showed “new calibration for improved transmission performance in garage shifts,” and comparing the calibration-identification information showed that this vehicle did not have the updated software installed.

Illustrations 1 and 2 show TPS percentage and EPC-solenoid amperage before and after the reprogram. The response time changed from about 4 seconds before the reprogram to 1 second after the reprogram. This was a much-improved response, and all symptoms were gone.

This is not so much about how 2001 and 2002 GM full-size vans can be fixed with a reprogram. The real issue is that there is no service bulletin to inform you of this problem! The traditional way of checking for known problems/fixes by checking service bulletins no longer applies.

GM makes it fairly easy with its online Web site, but with other brands it can be challenging at best. With Chrysler you can take the complete part number off the computer or access the software ID number with your scan tool. Chrysler dealers can enter this number into their Benchtop Programmer computer application and it should show any revised calibration numbers that supersede your original number. With Ford, the only way I know of checking for undocumented updates requires connecting the vehicle to the Ford WDS scan-tool system and beginning the reprogramming process.

Although this may be an obstacle in aftermarket transmission shops, this is one area in which new-car dealers have an advantage, as they can try a reprogram with very little effort and cost to see whether it helps. So if you are dealing with a new or odd problem, especially on a later-model vehicle, be sure to investigate software updates before you invest too much time in mechanical fixes.

Special thanks to Jeff Davis and Rockenbach Chevrolet for sharing this problem and fix.

Gregg Nader is a Sonnax technical specialist and a member of the TASC Force (Technical Automotive Specialties Committee), a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians. ©2005 Sonnax