TASC Force Tips

- Author: Gregg Nader, Sonnax

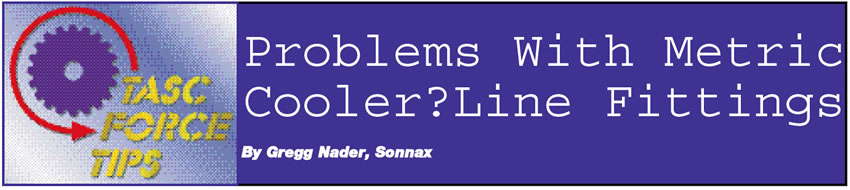

Few things slow down an R&R job like frozen cooler-line fittings. The metric cooler-line fittings used in Isuzu 4L30 applications and Toyota trucks with A340/30-40LE (see Figure 1) are frustrating enough to make you want to reach for the tubing cutter and start cutting rather than struggle with stubborn lines.

What is especially frustrating about these applications is that the line nut often will break loose and turn easily for one or two turns and then lock up tight. This is no picnic on cramped 4WD trucks with driveshafts and torsion-bar suspension in the way. Even after the line has been removed, the line nut will be just as hard to re-install. Nobody likes spending two hours on one line!

The reason these fittings are so difficult to remove is that the line nut expands as it is tightened into the fitting. These female fittings have no threads near the bottom, so as the nut is tightened, the leading threads of the male nut expand or flare out (see Figure 2). Even with new parts the line nut will install easily. However, once the nut is tightened, the expanded threads make it very difficult to remove and re-install.

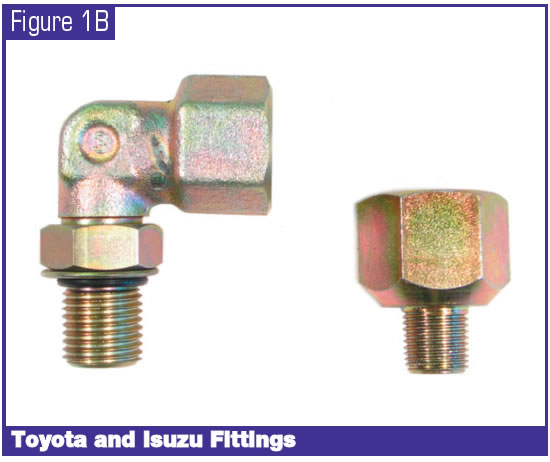

A quick fix to make the line easier to re-install is to chase the threads with a 16mm x 1.5mm thread die or spindle thread chaser (see source box). This removes a small amount of the expanded thread material from the line nut, making the line easier to re-install (see Figure 3). This saves a lot of time re-installing the line, but, unfortunately, if it ever needs to be removed again you are back to the same problem.

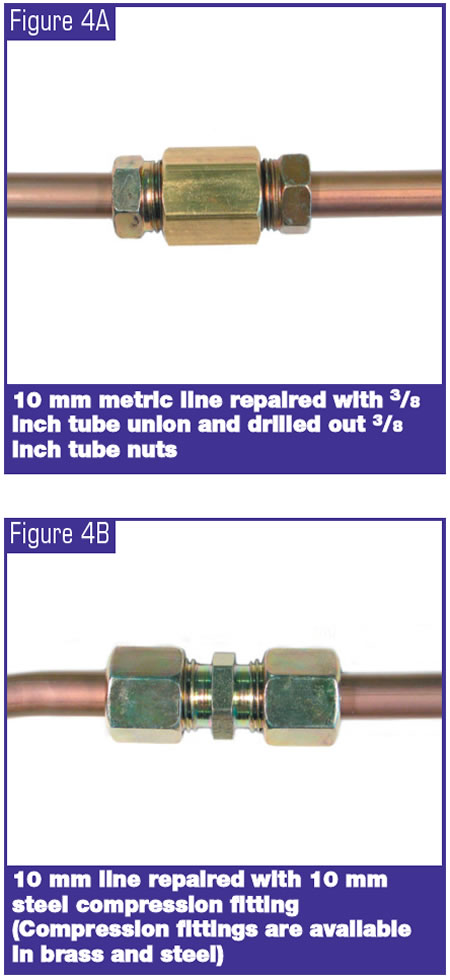

If it is necessary to cut the line there are a few options to patch the 10mm tubing. Just as with standard 3⁄8 tubing, options include tubing nuts and union, compression fittings or rubber hose (see figures 4a, 4b and 5). Replacement 10mm tubing is still very hard to come by, and most parts stores cannot even order it (see source box).

The best way to patch a cut cooler line is to double-flare the lines and join both ends with a tubing union. Unfortunately, 10mm metric tubing nuts and unions are not readily available. 10mm and 3⁄8 line are close enough in size that in a pinch, standard 3⁄8 tube nuts can be drilled out to fit over the 10mm line, then double-flared in place. Now the line ends can be joined with a standard 3⁄8 tubing union. A 3⁄8 flaring tool will work, but it will put deep crimps into the 10mm tubing. It is better to use a metric flaring tool to form the double flares, even though you are using 3⁄8 tube nuts.

If you patch the metal line with rubber hose, be sure to form a slight bubble flare on the line ends to keep the rubber hose from sliding off (see Figure 5). This will help prevent seeps and keeps the hose secure when the line gets hot. And NEVER use rubber fuel line, as it will certainly blow out. Use only transmission or power-steering return line that is compatible with ATF.

The TASC Force (Technical Automotive Specialties Committee) is a group of recognized industry technical specialists, transmission rebuilders and Sonnax Industries Inc. technicians.