Torque Converter Tech Tips

- Subject: Failure of starter ring gear

- Vehicle Application: 2006-08 Mitsubishi Galant V-6

- Essential Reading: Rebuilder, Diagnostician

- Author: Ed Lee

Torque-converter rebuilders have been reporting an increase in the number of failed ring gears on Mitsubishi Galant converters. Most of the failed ring gears are found on 2006-08 vehicles equipped with V-6 engines, and the failures seem to occur soon after the vehicle’s starter has been replaced.

Prior to the ring-gear failures, most customers report hearing a noise during startup followed by a condition of starter non-engagement. In most vehicles, the starter ring gear is on the outer diameter of the flex plate; when a ring gear fails, the flex plate must be replaced. On most Mitsubishi Galants, the ring gear is mounted directly on the converter, which makes it more difficult and much more expensive to replace. If the mileage of the vehicle or the appearance of the ATF makes the condition of the transmission questionable, replacing the converter and overhauling the transmission may be a better option than simply replacing the converter. If it is a low-mileage vehicle and the ATF appears to be in good condition, it is possible to replace only the ring gear.

Unfortunately, the location of the ring gear on the Galant converters makes it impossible to replace the gear without disassembling the converter. The welds used to secure the ring gear to the cover are too close to the TCC reacting surface to allow the ring gear to be replaced with the converter still assembled.

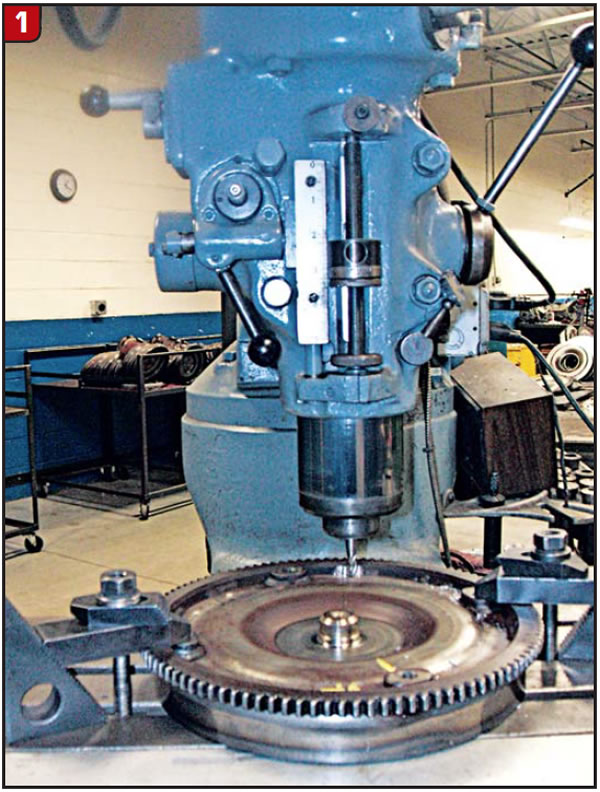

A ring gear typically can be removed from the converter by machining the welds off on a lathe. On some models of the Galant the ring gear is attached to the outer diameter of the converter cover. On the 2006-08 Galant, the ring gear is mounted to the front of the cover directly adjacent to the four mounting pads. The proximity of the ring gear to the mounting pads makes ring-gear removal more difficult. On those converters, a milling machine is a better option than machining the welds off on a lathe. If you are removing only one ring gear, you can secure the cover directly to the bed of the milling machine (Figure 1).

If you are removing more than one ring gear, you may want to mount your cover to a turntable. To remove the weld, plunge into the weld until the milling bit contacts the ring gear (the ring gear is harder than the weld and has a different feel on the cross feed). Do not force the milling bit into the ring gear. If you do, the bit will quickly become dull.

Why did the OEM ring gear fail?

Although the cause of the ring-gear damage is not totally clear, all known failures have been in vehicles with aftermarket replacement starters. The OEM replacement starter costs about $160, so customers often elect to go with an aftermarket starter that is about $40 less. In the short run, these customers did save $40, but in the long run they also had to pay for the R&R of the converter and the cost of the replacement converter and opted to go back to the OEM replacement starters to prevent repeat failures.

Ed Lee is a Sonnax Technical Specialist who writes on issues of interest to torque converter rebuilders. Sonnax supports the Torque Converter Rebuilders Association. Learn more about the group at www.tcraonline.com.

©Sonnax2010