Torque Converter Tech Tips

Subject: Woven-carbon lining on lockup piston worn away

Unit: GM 300mm converter

Essential Reading: Rebuilder, Diagnostician

Author: Lowell Caltrell

Complaint:

The customer was driving 55 mph when he noticed an engine-speed flare and realized that the lockup was no longer holding. There also was a growling noise when the converter tried to lock up. When the converter was cut open, there was fine black material resembling graphite on the stator assembly.

In our converter shop, a large number of 300mm converter pistons with woven-carbon linings are coming in with the friction material worn down to the metal. The lining on these pistons acts much like a thrust washer: As it wears, the converter end clearance increases.

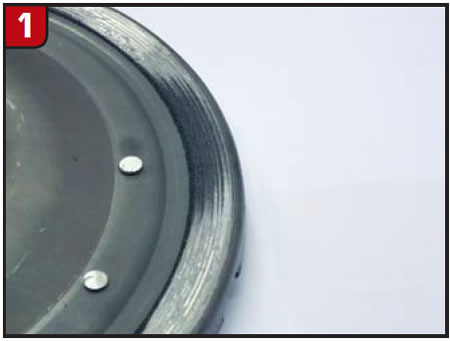

How many times has a converter with a woven clutch that’s worn down to the metal come into your shop? It might be your competitor’s rebuilt converter, an OE unit or one of your own units. On inspection, the unit looks pretty good. The O-ring, piston bore and turbine hub are fine. The unit seems mechanically sound, but the lining is gone or, in some instances, worn down to almost nothing (Figure 1).

Does what you see in the converter match up with the customer complaint? In most instances you might reason that the transmission is at fault and that the wear is due to a lack of application pressure. However, by examining the various stages of breakdown of this material, we can find a more-likely cause of failure.

If you catch this problem before the lining is completely gone, you can find fine black particles in the oil, because woven-carbon material does not wear like paper linings. In fact, it can be compared with a brake pad, since the more it is applied the thinner it gets. We have seen this situation regardless of the manufacturer of the converter.

The wear pattern starts at the outside diameter because the piston is dished. On inspection of used piston linings, we have recorded lining thickness as low as 0.005 inch on one part of the piston and 0.015 inch in other areas of the same piston. In the lower-right quadrant of the piston shown in Figure 2, the lining is only 0.005 inch thick, although the section at lower center is obviously thicker.

Figure 3 shows the next stage in the breakdown process. This piston was taken out of an OE unit that had never been rebuilt.

The unit in Figure 4 ran 45,000 miles on a good used lining and shows the final stage of breakdown.

We can easily conclude that this wear pattern is par for the course for this material. This pattern has even been observed in units with on/off lockup application, and especially in units where the lining takes up the end clearance, as it is almost always in contact with the cover.

General Motors allows a 20% wear factor in its remanufacturing process, which gives you a minimum thickness of 0.017 inch. There also are other factors such as surface finish, cleaning process and the type of oil used. Since this lining starts out at 0.022 inch thick, there is not a lot of room for error.

In our shop we have opted to change these linings 100% as we have a three-year, unlimited-mileage warranty, and it is a small price to pay for peace of mind. However, if you choose to reuse these linings, make sure you:

- Use a non-water-based cleaning process such as solvent.

- Maintain a finish of at least 20 RA on the cover.

- Reuse only linings that have the least wear possible, and check the thickness in several places, accepting only piston linings with the minimum thickness of 0.017 inch.

Lowell Caltrell is general manager of the converter shop at Precision Transmission Parts, Bakersfield, Calif., and has 20 years’ experience in the converter industry.

©2011 Sonnax