Torque Converter Tech Tips

- Subject: Pump-gear failure

- Unit: 4L60-E with 300mm converter

- Vehicle Application: 2002-2003 Olds Bravada, GMC Envoy, Chevy Trailblazer

- Essential Reading: Rebuilder, Diagnostician

- Author: Ed Lee

4L60-E, 300mm converter, 4.2L engine, code VJCX

Some GM vehicles with 4L60-E transmissions and 300-millimeter converters are experiencing higher-than-normal pump-gear failures. Affected vehicles are 2002-2003 Bravada, Envoy and Trailblazer (Dacco B-85 VJCX) equipped with the 4.2L engine. An easy way to identify this converter is that it is the only GM 300mm unit whose impeller overlaps the front cover rather than vice versa.

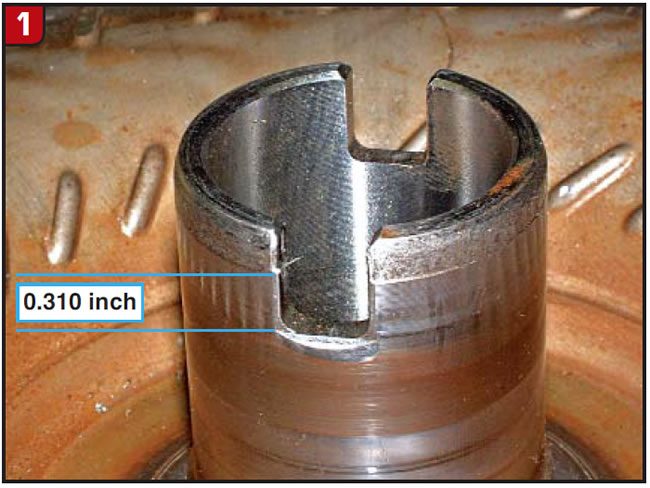

One possible cause of pump-gear failure could be insufficient engagement of the impeller drive hub into the pump gear due to excessive “stab depth.” Stab-depth measurement can be used as a method to evaluate a hub’s engagement into the pump gear. To check the stab depth of a converter, bolt the transmission to the engine and push the converter into the pump until the converter drive slot bottoms on the lugs of the pump gear. Once it’s in place, measure the gap between the flex plate and the mounting pads of the converter. This measurement should be a minimum of 0.125 inch to avoid damaging or destroying the pump but not more than 0.250 inch to prevent pump-gear failure. If you have only the converter and do not have access to the vehicle, you can get a rough idea of the stab depth by measuring the distance from the witness marks of the lug contact area of the impeller hub to the bottom of the drive slot.

This distance in Figure 1 measures about 0.310 inch, which is the same measurement that was obtained when the stab depth was checked in the vehicle.

The OE spec for the overall height on this VJCX converter is 6.500 inches; however, most of these OE converters measure only about 6.450 inches. With the exception of the Corvette, measuring between 6.254 and 6.275 inches, the OE spec for all other 300mm converters is 6.550 inches. In fact, the correct overall height for this VJCX converter should be 6.550 inches.

How to fix the problem

There are three different approaches being used to rectify this problem, but only one good one.

- Shimming the gap between flex plate and mounting pads. If the converter has an overall height of 6.500-6.550 inches and the stab depth is still too wide, shimming the gap between the flex plate and mounting pad is a viable option. However, if the overall height of the converter is 6.450 inches or less, the pilot will be pulled out of the crankshaft and will not have sufficient engagement when a shim is placed between the flex plate and the mounting pad of the converter. Be aware! If you are using a shim to correct the stab depth of a converter, you must be certain that you have sufficient pilot engagement in the crankshaft when you are finished.

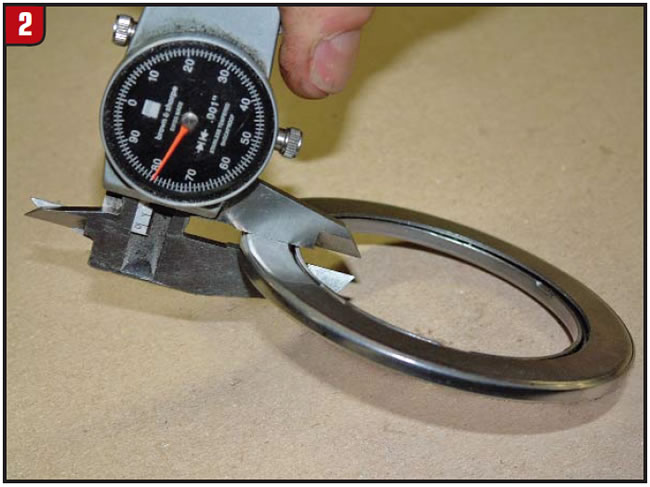

- Increasing internal clearance. A bearing upgrade with a 0.030-inch-thicker race is available for this converter (Figure 2). Some rebuilders have elected to replace the bearings without removing the 0.030 inch from the bearing’s original mating surface. This will increase the overall height of the converter by 0.060 inch but will also increase the internal clearance by 0.060 inch. Because increasing the internal clearance by 0.060 inch makes the converter less efficient, increases the stall and raises the operating temperature of the converter, this is not a good option.

- Installing a taller hub. The best option is to install a taller impeller hub. This method will allow the rebuilder to increase the overall height of the converter while maintaining the correct internal clearance.

Ed Lee is a Sonnax Technical Specialist who writes on issues of interest to torque converter rebuilders. Sonnax supports the Torque Converter Rebuilders Association. Learn more about the group at www.tcraonline.com.

©Sonnax2011